Open-pit mining involves the excavation of large surface pits to extract ore, providing easy access to minerals but causing significant environmental disruption and landscape alteration. In contrast, in-situ recovery extracts minerals by injecting solutions to dissolve ores underground, minimizing surface disturbance and reducing waste generation. The choice between these methods depends on ore type, depth, environmental impact, and economic feasibility.

Table of Comparison

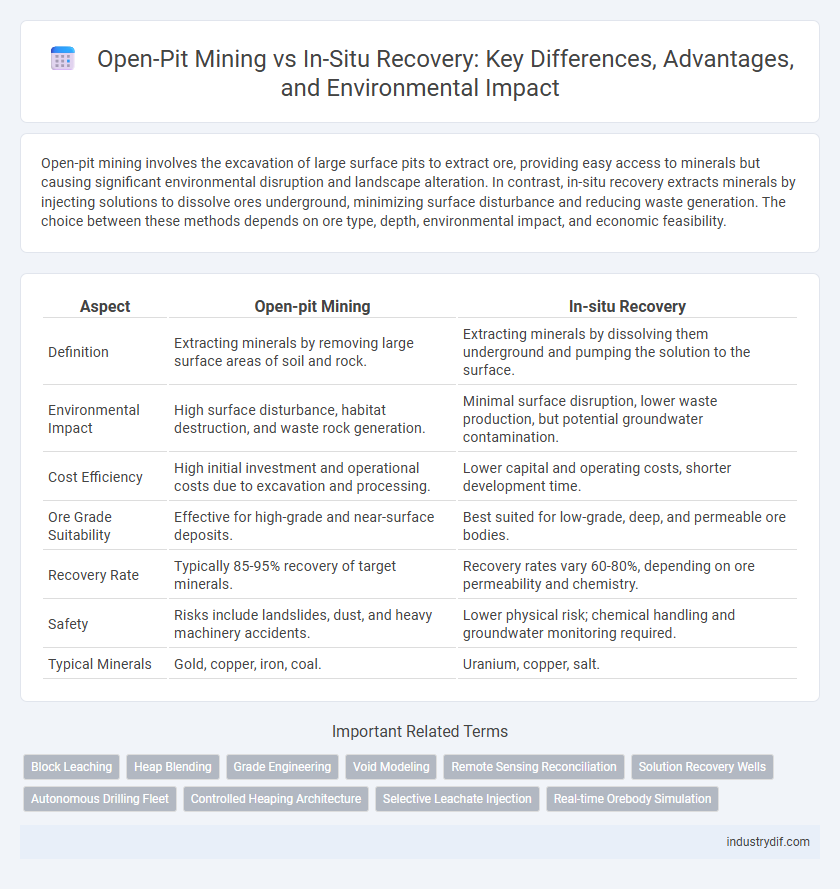

| Aspect | Open-pit Mining | In-situ Recovery |

|---|---|---|

| Definition | Extracting minerals by removing large surface areas of soil and rock. | Extracting minerals by dissolving them underground and pumping the solution to the surface. |

| Environmental Impact | High surface disturbance, habitat destruction, and waste rock generation. | Minimal surface disruption, lower waste production, but potential groundwater contamination. |

| Cost Efficiency | High initial investment and operational costs due to excavation and processing. | Lower capital and operating costs, shorter development time. |

| Ore Grade Suitability | Effective for high-grade and near-surface deposits. | Best suited for low-grade, deep, and permeable ore bodies. |

| Recovery Rate | Typically 85-95% recovery of target minerals. | Recovery rates vary 60-80%, depending on ore permeability and chemistry. |

| Safety | Risks include landslides, dust, and heavy machinery accidents. | Lower physical risk; chemical handling and groundwater monitoring required. |

| Typical Minerals | Gold, copper, iron, coal. | Uranium, copper, salt. |

Overview of Open-pit Mining and In-situ Recovery

Open-pit mining involves extracting minerals from a large, open excavation on the surface, enabling access to ore deposits close to the earth's surface with heavy machinery. In-situ recovery (ISR) extracts minerals by injecting chemical solutions into the ore body underground, dissolving the target minerals, and pumping the solution to the surface for processing, minimizing surface disturbance. Open-pit mining is typically used for ores like copper and gold with shallow deposits, while ISR is preferred for uranium and other minerals located in permeable rock formations at greater depths.

Key Differences Between Extraction Methods

Open-pit mining involves excavating large surface pits to extract minerals, making it suitable for shallow deposits with high ore grades, while in-situ recovery (ISR) uses chemical solutions to dissolve and pump minerals from deep underground, minimizing surface disturbance. Open-pit mining generates significant waste rock and requires extensive land alteration, whereas ISR reduces environmental impact by limiting surface footprint and lowering waste production. Efficiency in ore recovery varies, with open-pit offering higher extraction rates for large, accessible deposits and ISR providing cost-effective extraction in permeable ore bodies with suitable hydrological conditions.

Environmental Impact Comparison

Open-pit mining typically results in significant land disturbance, habitat destruction, and generation of large amounts of waste rock, leading to soil erosion and water pollution. In-situ recovery minimizes surface disruption by injecting solvents underground to dissolve minerals, reducing landscape alteration and tailings production, but it poses risks of groundwater contamination if not managed properly. Environmental impact comparisons highlight that in-situ recovery offers a lower footprint and less surface ecosystem damage, though strict monitoring is required to prevent subsurface water quality degradation.

Operational Processes of Open-pit Mining

Open-pit mining involves the removal of large volumes of overburden to access near-surface mineral deposits, employing heavy machinery such as drill rigs, excavators, and haul trucks to extract and transport ore. The process includes drilling, blasting, loading, and hauling, with an emphasis on efficient material handling and waste management to optimize extraction rates. Operational success depends on precise scheduling, equipment maintenance, and strict environmental management protocols to minimize surface disturbance and ensure worker safety.

Technological Advancements in In-situ Recovery

In-situ recovery (ISR) technology has advanced significantly, employing sophisticated leaching solutions that selectively dissolve minerals while minimizing surface disturbance and environmental impact. Innovations such as real-time monitoring systems and automated injection-extraction wells enhance the precision and efficiency of mineral extraction in ISR compared to traditional open-pit mining. These technological improvements reduce operational costs, limit waste generation, and enable access to deeper ore deposits that are economically unfeasible with open-pit methods.

Economic Considerations and Cost Analysis

Open-pit mining involves high initial capital expenditure and operational costs due to extensive excavation and equipment needs, impacting overall economic feasibility. In-situ recovery (ISR) offers lower upfront costs and reduced environmental restoration expenses, enhancing cost-effectiveness for suitable ore deposits. Economic considerations must include ore grade, extraction efficiency, and long-term environmental liabilities to determine the most financially viable mining method.

Resource Suitability for Each Method

Open-pit mining is highly suitable for shallow, near-surface ore bodies with large, economically viable deposits, particularly in hard rock formations such as copper or gold. In-situ recovery is ideal for deep, sedimentary deposits like uranium or potash where the ore is amenable to leaching without significant surface disturbance. Resource characteristics such as depth, ore permeability, and mineral solubility primarily determine the optimal extraction method for maximizing efficiency and minimizing environmental impact.

Safety and Worker Health Factors

Open-pit mining exposes workers to hazards like rock falls, dust inhalation, and heavy machinery accidents, increasing the risk of respiratory diseases and physical injuries. In-situ recovery significantly reduces surface exposure by extracting minerals directly from underground deposits using chemical solutions, minimizing dust and physical hazards, thus improving worker safety and health outcomes. However, managing chemical exposure and groundwater contamination remains essential to safeguard environmental and occupational health in in-situ recovery operations.

Regulatory Compliance and Permitting

Open-pit mining requires extensive regulatory compliance involving environmental impact assessments, land disturbance permits, and reclamation plans due to its surface excavation nature. In-situ recovery faces stringent groundwater protection regulations and must secure permits related to fluid injection and chemical use to prevent contamination. Both methods demand comprehensive monitoring and adherence to federal and state mining laws to ensure environmental safety and operational legality.

Future Trends in Mining Extraction Techniques

Open-pit mining continues to evolve with advancements in automation, drone technology, and real-time data analytics enhancing operational efficiency and environmental monitoring. In-situ recovery methods are gaining traction due to their lower surface disturbance and reduced water usage, driven by innovations in solvent chemistry and precision injection techniques. Emerging trends emphasize sustainability, with hybrid approaches combining open-pit and in-situ processes to optimize resource extraction while minimizing ecological impact.

Related Important Terms

Block Leaching

Block leaching, a method commonly associated with in-situ recovery, involves leaching valuable minerals directly within the ore body without extensive excavation, which contrasts with block extraction in open-pit mining that requires removal of large volumes of overburden and ore in discrete blocks. This in-situ approach minimizes surface disturbance and reduces operational costs while ensuring selective extraction of minerals such as copper and uranium compared to the more invasive and capital-intensive open-pit mining techniques.

Heap Blending

Heap blending in open-pit mining optimizes ore grade by stacking heterogeneous materials to enhance metal recovery rates through uniform leaching processes. In contrast, in-situ recovery bypasses heap blending by dissolving minerals directly within the deposit, minimizing surface disturbance but requiring precise hydrogeological control for efficient extraction.

Grade Engineering

Open-pit mining involves extracting high-grade ore from large surface excavations, enabling efficient grade control and selective mining to maximize metal recovery. In-situ recovery minimizes environmental disturbance by leaching minerals directly from ore bodies underground, but offers limited grade engineering options due to the dilution of ore during the leaching process.

Void Modeling

Void modeling in open-pit mining involves detailed 3D simulations to predict the volume and stability of extracted ore voids, essential for optimizing pit design and ensuring safe slope management. In contrast, void modeling in in-situ recovery focuses on simulating fluid flow pathways and porosity changes within the ore body to predict subsidence and environmental impact during leaching operations.

Remote Sensing Reconciliation

Remote sensing reconciliation enhances open-pit mining by providing precise spatial data for excavation progress and environmental monitoring, while in-situ recovery benefits from real-time subsurface imaging to optimize solution injection and extraction processes. Integrating satellite and drone-based remote sensing technologies ensures accurate resource estimation and minimizes ecological impact in both mining methods.

Solution Recovery Wells

Solution recovery wells in in-situ recovery mining enable the controlled extraction of minerals by injecting and pumping leach solutions directly into the ore body, minimizing surface disruption compared to open-pit mining, which relies on large-scale excavation. These wells optimize resource recovery with reduced environmental impact, enhancing efficiency in extracting minerals such as uranium and copper.

Autonomous Drilling Fleet

Autonomous drilling fleets in open-pit mining enhance operational efficiency by enabling continuous, precise excavation with reduced human intervention, leading to increased productivity and safety. In contrast, in-situ recovery relies less on such machinery, focusing instead on chemical extraction methods that limit the need for extensive drilling fleets.

Controlled Heaping Architecture

Controlled heaping architecture in open-pit mining enables efficient extraction by systematically stacking overburden and ore to optimize stability and minimize environmental impact. In-situ recovery leverages controlled subsurface fluid injection and extraction, preserving geological structures without extensive surface disturbance, offering a more sustainable alternative for suitable ore bodies.

Selective Leachate Injection

Open-pit mining involves large-scale excavation altering the surface landscape, while in-situ recovery utilizes selective leachate injection to dissolve and extract minerals directly from ore bodies underground without extensive surface disruption. Selective leachate injection enhances mineral recovery efficiency by targeting specific ore zones, minimizing environmental impact compared to traditional open-pit operations.

Real-time Orebody Simulation

Open-pit mining relies on real-time orebody simulation to optimize excavation sequences and minimize waste extraction, using high-resolution geospatial data and advanced modeling algorithms. In contrast, in-situ recovery employs continuous reservoir monitoring and real-time flow simulation to enhance solution injection strategies, ensuring efficient mineral dissolution while minimizing environmental impact.

Open-pit Mining vs In-situ Recovery Infographic

industrydif.com

industrydif.com