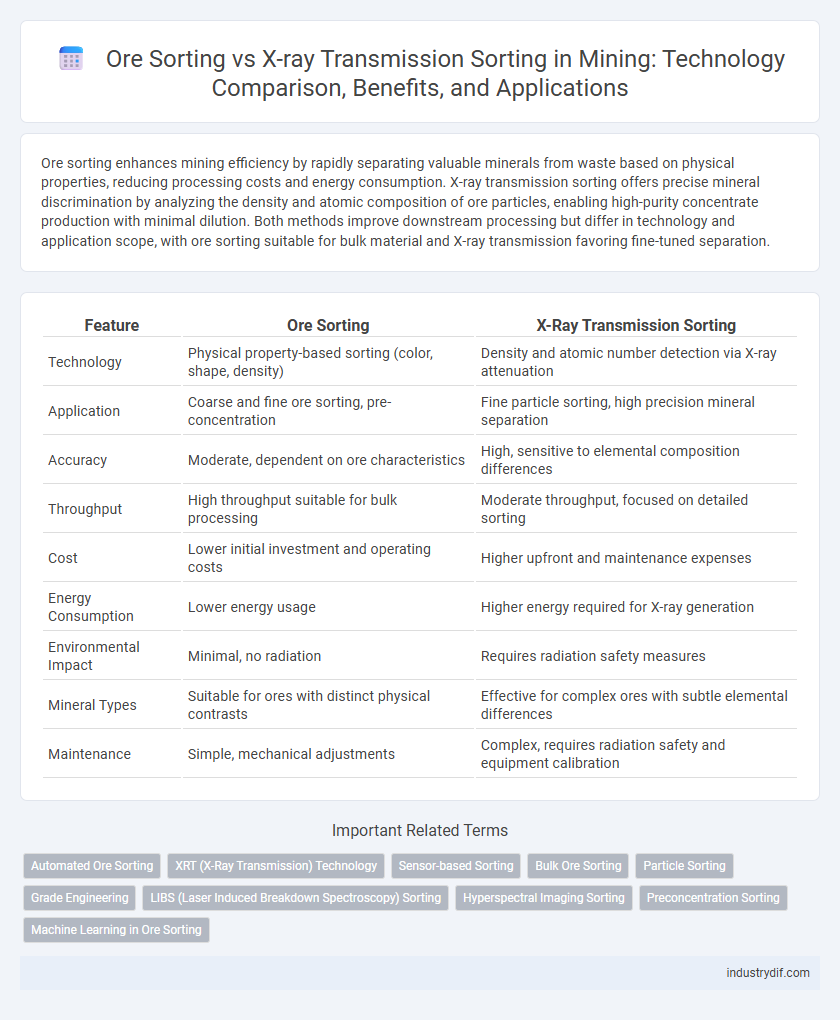

Ore sorting enhances mining efficiency by rapidly separating valuable minerals from waste based on physical properties, reducing processing costs and energy consumption. X-ray transmission sorting offers precise mineral discrimination by analyzing the density and atomic composition of ore particles, enabling high-purity concentrate production with minimal dilution. Both methods improve downstream processing but differ in technology and application scope, with ore sorting suitable for bulk material and X-ray transmission favoring fine-tuned separation.

Table of Comparison

| Feature | Ore Sorting | X-Ray Transmission Sorting |

|---|---|---|

| Technology | Physical property-based sorting (color, shape, density) | Density and atomic number detection via X-ray attenuation |

| Application | Coarse and fine ore sorting, pre-concentration | Fine particle sorting, high precision mineral separation |

| Accuracy | Moderate, dependent on ore characteristics | High, sensitive to elemental composition differences |

| Throughput | High throughput suitable for bulk processing | Moderate throughput, focused on detailed sorting |

| Cost | Lower initial investment and operating costs | Higher upfront and maintenance expenses |

| Energy Consumption | Lower energy usage | Higher energy required for X-ray generation |

| Environmental Impact | Minimal, no radiation | Requires radiation safety measures |

| Mineral Types | Suitable for ores with distinct physical contrasts | Effective for complex ores with subtle elemental differences |

| Maintenance | Simple, mechanical adjustments | Complex, requires radiation safety and equipment calibration |

Introduction to Ore Sorting Technologies

Ore sorting technologies enhance mineral processing efficiency by selectively separating valuable ore from waste rock based on physical or chemical properties. X-ray transmission sorting utilizes differences in material density and atomic composition to identify and separate ore particles, offering precise sorting capabilities for complex ores. Compared to traditional ore sorting methods, X-ray transmission provides higher accuracy and improved recovery rates, making it essential in modern mining operations.

Overview of X-ray Transmission (XRT) Sorting

X-ray Transmission (XRT) sorting technology utilizes density differences to separate ore particles, enabling precise sorting based on material composition and reducing waste. The system detects variations in X-ray absorption, distinguishing valuable minerals from gangue with high accuracy, improving recovery rates and processing efficiency. XRT sorting is suitable for a range of ore types, including complex polymetallic ores, offering enhanced throughput and lower operational costs compared to traditional ore sorting methods.

Principles and Mechanisms of Ore Sorting

Ore sorting employs sensors such as optical, magnetic, or near-infrared to identify and separate valuable minerals from waste based on physical or chemical properties. X-ray transmission sorting utilizes differences in material density and atomic number to detect and differentiate ore particles by measuring the attenuation of X-ray beams passing through the material. Both methods improve ore grade and recovery by selectively removing gangue before processing, reducing energy consumption and downstream processing costs.

Comparative Efficiency: Traditional Ore Sorting vs XRT

X-ray transmission (XRT) sorting offers superior precision and efficiency compared to traditional ore sorting by leveraging detailed density and atomic number analysis to differentiate ores. Traditional ore sorting methods, such as sensor-based or manual techniques, often struggle with lower accuracy and increased material loss, limiting recovery rates. XRT technology enhances ore grade control, reduces waste, and improves overall processing throughput, making it a preferred choice for modern mining operations.

Material Suitability: What Each Sorting Method Handles Best

Ore sorting excels in handling coarse, high-density materials like chromite and iron ore by efficiently separating valuable minerals from waste rock. X-ray transmission sorting is best suited for finer particles and complex ores, particularly those containing varying chemical compositions such as lead-zinc and copper ores. Each method optimizes recovery based on mineral density and composition, maximizing resource extraction efficiency.

Technological Innovations in Ore Sorting

Technological innovations in ore sorting have significantly enhanced the efficiency of mineral processing by integrating advanced sensor-based techniques. X-ray transmission sorting utilizes differential absorption properties to accurately distinguish ore from waste, enabling high-precision separation and reducing downstream processing costs. In contrast, traditional ore sorting methods rely on color, shape, or size, making X-ray transmission sorting superior in detecting fine-grained minerals and improving overall recovery rates.

Environmental Impact: Ore Sorting vs XRT Systems

Ore sorting significantly reduces environmental impact by minimizing waste sent to tailings and lowering energy consumption during mineral processing. X-ray transmission (XRT) sorting enhances selectivity and recovery rates but involves higher energy use and more complex equipment, potentially increasing its environmental footprint. Efficient ore sorting technologies prioritize reducing carbon emissions and water usage, contributing to greener mining operations.

Cost Analysis and ROI of Each Sorting Method

Ore sorting offers lower upfront equipment costs and reduced operational expenses compared to X-ray transmission sorting, resulting in faster return on investment (ROI) for mining operations targeting coarse particle separation. X-ray transmission sorting, though more capital intensive due to advanced sensor technology and higher maintenance requirements, delivers superior precision in elemental discrimination, potentially increasing ore grade and profitability over longer processing periods. Cost analysis favors ore sorting for projects with limited budgets and shorter lifespans, while X-ray transmission sorting justifies its ROI in high-value, complex ore deposits requiring detailed material characterization.

Case Studies: Successful Implementations in Mining

Case studies demonstrate that ore sorting using sensor-based technologies, particularly X-ray transmission (XRT) sorting, significantly enhances ore grade and reduces waste, as evidenced by implementations in copper and diamond mining operations. In a major copper mine, XRT sorting improved ore recovery by over 15% while cutting energy consumption and downstream processing costs. Diamond producers report up to 30% increases in recovered carats through XRT sorting, highlighting its precision in separating high-value minerals from low-grade material.

Future Trends in Ore and XRT Sorting Technologies

Future trends in ore sorting emphasize advancements in X-ray transmission (XRT) sorting technologies, leveraging improved sensor resolution and real-time data analytics to enhance ore grade control and reduce processing costs. Integration of artificial intelligence and machine learning algorithms is enabling more precise discrimination between ore and waste, increasing overall sorting efficiency and recovery rates. Development of portable, modular XRT units promises greater flexibility and adaptability for diverse mining operations, supporting sustainable resource management and reducing environmental impact.

Related Important Terms

Automated Ore Sorting

Automated ore sorting enhances mining efficiency by using advanced sensors to differentiate valuable minerals from waste rock, significantly reducing processing costs and increasing recovery rates. X-ray transmission sorting, a subset of automated sorting, provides precise material density analysis, enabling higher accuracy in separating ore based on atomic composition compared to traditional optical sorting methods.

XRT (X-Ray Transmission) Technology

X-ray Transmission (XRT) technology in ore sorting uses density-based differentiation to precisely separate valuable minerals from waste, enhancing recovery rates and reducing processing costs. Compared to traditional ore sorting methods, XRT offers higher accuracy in detecting fine-grained ores and is effective in handling materials with varying moisture content and particle size distributions.

Sensor-based Sorting

Ore sorting techniques leverage sensor-based technologies to enhance mineral processing efficiency by distinguishing valuable ore from waste rock. X-ray transmission sorting, a key sensor-based method, utilizes differences in material density and atomic composition to accurately separate ore particles, reducing energy consumption and increasing recovery rates compared to traditional sorting methods.

Bulk Ore Sorting

Bulk Ore Sorting enhances mineral recovery by processing large volumes of ore and rejecting low-grade material early, increasing overall plant efficiency and reducing downstream processing costs. Compared to X-ray transmission sorting, which uses element-specific density and atomic number differences for precise ore classification, bulk ore sorting relies on broader physical properties like density and particle size, making it suitable for high-throughput applications in mining operations.

Particle Sorting

Ore sorting utilizes optical and sensor-based technologies to separate valuable minerals from waste rock by analyzing particle size, shape, and composition, enhancing overall processing efficiency. X-ray transmission sorting specifically leverages differences in material density and atomic number, enabling precise particle sorting by detecting variations in X-ray absorption, which improves recovery rates in complex ore bodies.

Grade Engineering

Ore sorting enhances Grade Engineering by selectively separating high-grade minerals from low-grade ores, maximizing resource efficiency and reducing processing costs. X-ray transmission sorting further improves grade control by accurately identifying mineral density variations, enabling precise separation and higher quality concentrate output.

LIBS (Laser Induced Breakdown Spectroscopy) Sorting

LIBS sorting leverages laser-induced plasma emission spectra to precisely analyze elemental composition, enabling efficient separation of valuable ores from gangue with higher accuracy than X-ray transmission sorting, which primarily relies on density and atomic number differences. LIBS technology offers rapid, real-time, and non-destructive sorting capabilities suitable for complex mineral matrices, improving yield and reducing processing costs in mining operations.

Hyperspectral Imaging Sorting

Hyperspectral imaging sorting utilizes detailed spectral data to identify and separate ore minerals with high precision, outperforming traditional X-ray transmission sorting which primarily relies on density differences. This advanced technique enhances ore grade recovery and reduces waste by capturing chemical and mineralogical variations invisible to X-rays.

Preconcentration Sorting

Ore sorting uses physical properties like color and shape to separate valuable minerals from waste, enabling efficient preconcentration of ores before milling. X-ray transmission sorting identifies differences in atomic density to selectively preconcentrate ores, enhancing recovery rates and reducing energy consumption in downstream processing.

Machine Learning in Ore Sorting

Machine learning enhances ore sorting by enabling adaptive algorithms to analyze complex sensor data, improving the accuracy and efficiency of both traditional ore sorting and advanced X-ray transmission sorting technologies. These intelligent systems optimize mineral recovery rates and reduce waste by dynamically adjusting sorting parameters based on real-time material characteristics.

Ore sorting vs X-ray transmission sorting Infographic

industrydif.com

industrydif.com