Room and Pillar mining involves excavating large rooms while leaving pillars of ore to support the roof, providing stability in flat-lying deposits. Continuous mining utilizes a mechanized shearer or continuous miner to extract ore without drilling and blasting, increasing efficiency and safety in coal seams and other soft minerals. The choice between these methods depends on geological conditions, resource geometry, and operational goals, balancing extraction rate with mine safety.

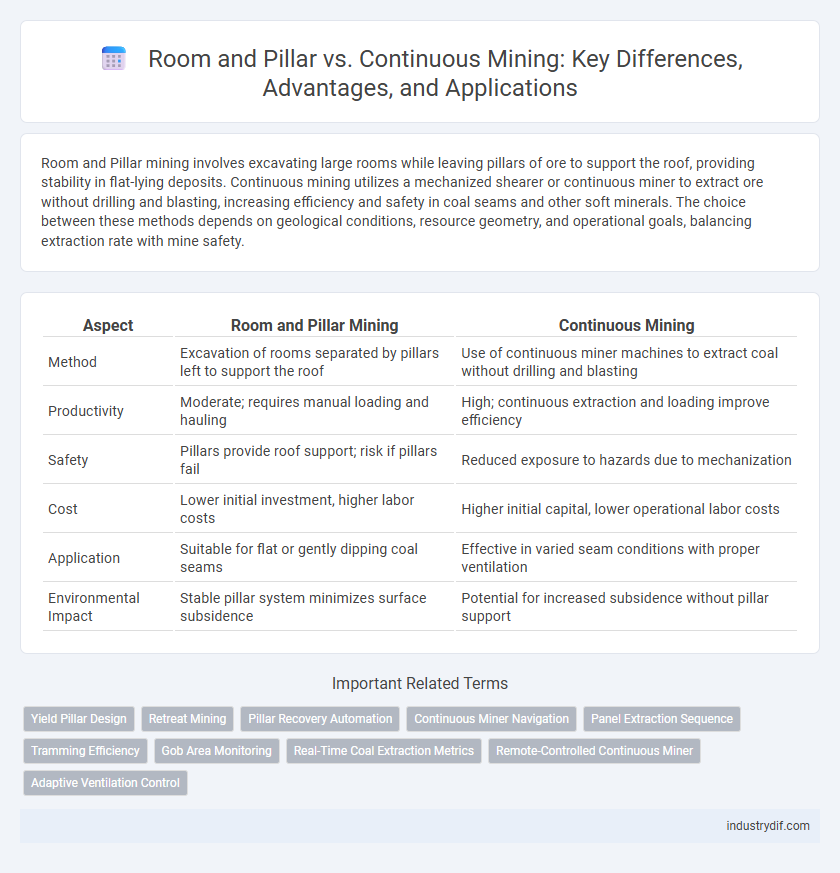

Table of Comparison

| Aspect | Room and Pillar Mining | Continuous Mining |

|---|---|---|

| Method | Excavation of rooms separated by pillars left to support the roof | Use of continuous miner machines to extract coal without drilling and blasting |

| Productivity | Moderate; requires manual loading and hauling | High; continuous extraction and loading improve efficiency |

| Safety | Pillars provide roof support; risk if pillars fail | Reduced exposure to hazards due to mechanization |

| Cost | Lower initial investment, higher labor costs | Higher initial capital, lower operational labor costs |

| Application | Suitable for flat or gently dipping coal seams | Effective in varied seam conditions with proper ventilation |

| Environmental Impact | Stable pillar system minimizes surface subsidence | Potential for increased subsidence without pillar support |

Overview of Room and Pillar Mining

Room and pillar mining involves excavating a series of open spaces, or "rooms," while leaving behind pillars of untouched material to support the roof, making it suitable for flat-lying, stable coal seams. This method maximizes safety by maintaining structural integrity and allows for selective extraction of ore, minimizing waste. Compared to continuous mining, room and pillar offers greater control over mine layout and stability but typically results in lower extraction rates.

Principles of Continuous Mining

Continuous mining operates by utilizing a rotating drum equipped with carbide teeth to cut coal or ore directly from the seam without the need for drilling and blasting, enhancing efficiency and safety. Unlike room and pillar mining, which relies on creating pillars to support the roof, continuous mining continuously extracts material while concurrently supporting the roof with roof bolts and mesh, reducing ground control hazards. This mechanized method enables higher production rates, continuous material flow, and improved resource recovery, making it ideal for flat-lying deposits in underground coal mining.

Key Differences Between Room and Pillar and Continuous Mining

Room and Pillar mining involves excavating a series of rooms while leaving pillars of ore to support the roof, making it ideal for flat-lying, stable deposits, whereas Continuous Mining uses a mechanized machine with a rotating drum to cut and gather ore without blasting, suitable for high-production environments. Room and Pillar offers better ground control through pillars but generally has lower recovery rates compared to Continuous Mining, which excels in productivity and resource extraction. Continuous Mining systems reduce labor intensity and improve safety by minimizing manual handling and blasting operations commonly present in Room and Pillar mining.

Equipment Used in Each Mining Method

Room and pillar mining primarily utilizes continuous miners, roof bolters, and shuttle cars to extract and transport coal while maintaining structural stability. Continuous mining employs continuous miners and conveyor systems, enabling a more automated and efficient extraction process that reduces manual handling. Both methods rely on specialized equipment tailored to maximize safety and productivity based on geological conditions and mining objectives.

Geological Suitability and Application

Room and pillar mining excels in flat-lying, stable geological formations with strong roof conditions, allowing for systematic extraction while preserving ground stability. Continuous mining is suited for softer, less stable strata where automated cutting machines efficiently extract coal or ore without extensive rock support. Geological factors such as seam thickness, rock hardness, and fault presence critically determine the choice between room and pillar and continuous mining techniques for optimized resource recovery.

Production Rates and Efficiency Comparison

Room and pillar mining offers moderate production rates with a stable extraction process, ideal for flat-lying coal seams, while continuous mining delivers higher production rates through mechanized, continuous material removal. Continuous mining systems maximize operational efficiency by reducing downtime and enabling faster resource recovery, contrasting with the more labor-intensive and segmented extraction of room and pillar methods. Production efficiency in continuous mining typically surpasses room and pillar due to automation and streamlined workflows, resulting in increased output and lower operational costs.

Safety Considerations in Both Methods

Room and Pillar mining enhances safety by maintaining pillars that support the roof, reducing the risk of collapses, while Continuous Mining involves automated machinery that minimizes human exposure to hazardous areas. Continuous Mining allows for real-time monitoring systems and remote operation, which further improves worker safety compared to traditional Room and Pillar methods. Both methods require rigorous ventilation and ground control measures to mitigate risks associated with dust, gas buildup, and rock falls.

Environmental Impacts of Mining Techniques

Room and pillar mining minimizes surface subsidence and reduces water contamination by leaving pillars of coal intact for structural support, which helps preserve surrounding ecosystems. Continuous mining, while increasing resource recovery efficiency, often leads to higher emissions and greater disturbance of underground air quality due to constant machinery operation. Selecting between these methods involves balancing mineral extraction rates against the potential for environmental degradation, particularly in terms of soil stability, groundwater protection, and noise pollution.

Cost Analysis: Room and Pillar vs Continuous Mining

Room and Pillar mining typically involves lower upfront equipment costs but incurs higher labor and maintenance expenses due to its manual-intensive operations. Continuous mining, while demanding significant initial capital investment in advanced machinery, often results in reduced operating costs and higher productivity through automation and continuous extraction. A comprehensive cost analysis must consider equipment depreciation, labor efficiency, production rates, and long-term operational expenditures to determine the most economical method for specific mineral deposits.

Future Trends and Innovations in Mining Methods

Future trends in mining emphasize automation and AI integration, where continuous mining enhances efficiency by enabling simultaneous extraction and material transport, reducing operational downtime. Room and pillar mining is evolving with sensor technology and real-time data analytics, improving mine safety and stability through predictive maintenance and optimized pillar design. Innovations such as electric-powered continuous miners and advanced ventilation controls promise lower environmental impact and increased energy efficiency in both mining methods.

Related Important Terms

Yield Pillar Design

Room and pillar mining achieves higher yield through precise pillar design, optimizing pillar size to balance ore recovery and ground stability. Continuous mining enhances production efficiency but requires robust yield pillar strategies to maintain structural integrity and maximize extraction in varying geological conditions.

Retreat Mining

Retreat mining in room and pillar mining involves systematically extracting the pillars after the initial mining phase, maximizing resource recovery but increasing the risk of ground collapse. Continuous mining uses powered cutting machines to extract minerals efficiently without blasting, though it typically limits pillar removal, impacting the final extraction rate compared to retreat mining methods.

Pillar Recovery Automation

Pillar recovery automation in room and pillar mining enhances safety and efficiency by remotely controlling extraction processes of pillars, reducing manual labor and minimizing collapse risks. Continuous mining allows for faster material extraction but lacks the precision of automated pillar recovery systems critical for maintaining mine stability during resource reclamation.

Continuous Miner Navigation

Continuous Miner Navigation employs advanced automated guidance systems and real-time data analytics to enhance operational precision and safety, outperforming Room and Pillar methods that rely heavily on manual control. This technology optimizes extraction patterns, reduces downtime, and improves overall productivity in underground mining environments.

Panel Extraction Sequence

Room and pillar mining utilizes a systematic panel extraction sequence, where pillars provide structural support while panels are mined sequentially to maintain stability, optimizing safety and resource recovery. Continuous mining employs a more automated, uninterrupted panel extraction process, enhancing productivity but requiring careful planning to avoid over-extraction and ground control issues.

Tramming Efficiency

Room and Pillar mining offers higher tramming efficiency due to its structured layout of open rooms and pillars, enabling smoother equipment movement and reduced travel time compared to Continuous Mining. Continuous Mining systems, while more flexible in face extraction, often experience lower tramming efficiency because of the irregular tunnel patterns and frequent equipment repositioning.

Gob Area Monitoring

Room and Pillar mining requires meticulous gob area monitoring to ensure pillar stability and prevent subsidence, using sensors to track stress and deformation in real-time. Continuous mining integrates automated monitoring systems within the gob to optimize extraction rates while maintaining safety by detecting potential collapses early.

Real-Time Coal Extraction Metrics

Room and Pillar mining offers stable void recovery with real-time sensors monitoring pillar stress and extraction rates, enabling precise safety adjustments. Continuous Mining provides higher coal output rates with automated machine telemetry delivering instant data on extraction efficiency and cycle times for optimized productivity.

Remote-Controlled Continuous Miner

Room and pillar mining employs a method of excavating ore while leaving pillars of material to support the roof, optimizing stability but limiting extraction efficiency; continuous mining, especially with remote-controlled continuous miners, enhances safety by allowing operators to control machinery from a distance, increasing productivity through uninterrupted material extraction and reducing human exposure to hazardous conditions. Remote-controlled continuous miners integrate advanced automation and sensor technology, enabling precise operation in complex underground environments while minimizing downtime and operational risks compared to traditional room and pillar techniques.

Adaptive Ventilation Control

Adaptive ventilation control enhances safety and energy efficiency in both room and pillar and continuous mining by monitoring air quality and adjusting airflow based on real-time data. This technology optimizes ventilation distribution, reducing methane accumulation risks and improving mine atmosphere management across differing mining methods.

Room and Pillar vs Continuous Mining Infographic

industrydif.com

industrydif.com