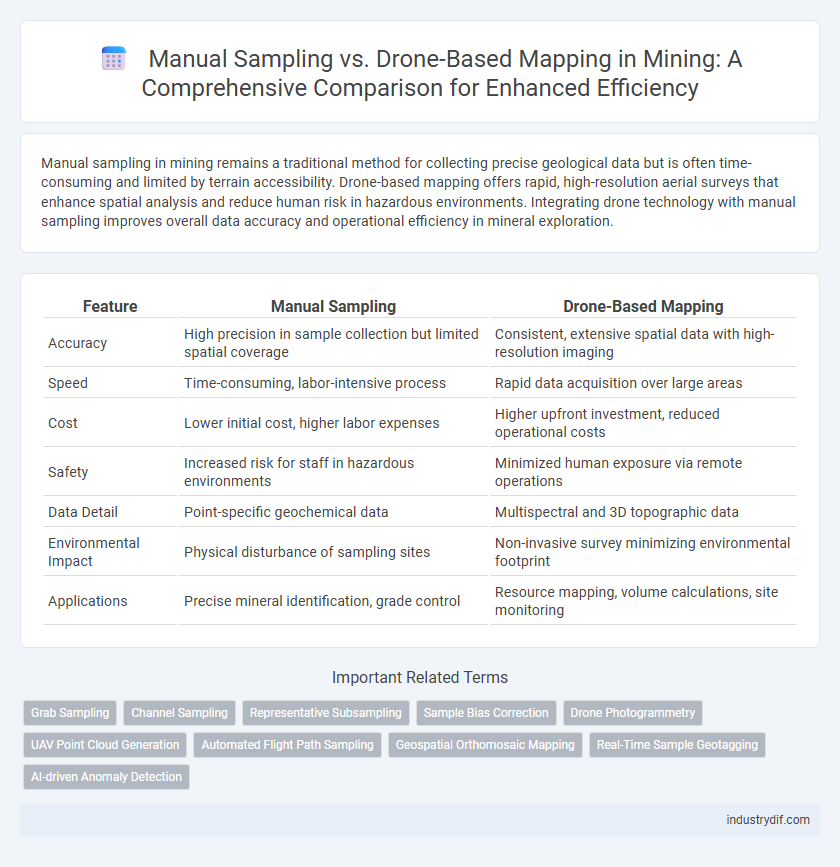

Manual sampling in mining remains a traditional method for collecting precise geological data but is often time-consuming and limited by terrain accessibility. Drone-based mapping offers rapid, high-resolution aerial surveys that enhance spatial analysis and reduce human risk in hazardous environments. Integrating drone technology with manual sampling improves overall data accuracy and operational efficiency in mineral exploration.

Table of Comparison

| Feature | Manual Sampling | Drone-Based Mapping |

|---|---|---|

| Accuracy | High precision in sample collection but limited spatial coverage | Consistent, extensive spatial data with high-resolution imaging |

| Speed | Time-consuming, labor-intensive process | Rapid data acquisition over large areas |

| Cost | Lower initial cost, higher labor expenses | Higher upfront investment, reduced operational costs |

| Safety | Increased risk for staff in hazardous environments | Minimized human exposure via remote operations |

| Data Detail | Point-specific geochemical data | Multispectral and 3D topographic data |

| Environmental Impact | Physical disturbance of sampling sites | Non-invasive survey minimizing environmental footprint |

| Applications | Precise mineral identification, grade control | Resource mapping, volume calculations, site monitoring |

Introduction to Sampling Methods in Mining

Manual sampling in mining involves direct collection of ore or soil samples by workers at specific locations, providing high accuracy but limited spatial coverage and labor-intensive processes. Drone-based mapping employs advanced aerial imaging and sensors to capture large-scale geospatial data rapidly, enabling efficient identification of mineral deposits and terrain variations. Combining these methods enhances exploration precision by integrating detailed ground-level data with extensive aerial surveys.

Manual Sampling: Processes and Challenges

Manual sampling in mining involves physically collecting rock, soil, or mineral samples from specific sites to analyze ore quality and composition, essential for accurate resource estimation. The process is labor-intensive, time-consuming, and prone to errors due to human factors, difficult terrain, and inconsistent sample sizes. Challenges include safety risks, limited spatial coverage, and delays in data acquisition, which can impact decision-making and operational efficiency.

Drone-Based Mapping: Technology Overview

Drone-based mapping in mining utilizes advanced GPS, LiDAR, and multispectral imaging technologies to capture high-resolution aerial data, enabling precise topographical modeling and mineral deposit analysis. Automated flight paths and real-time data processing enhance spatial accuracy and operational efficiency compared to manual sampling. Integration with GIS software allows for dynamic site monitoring, reducing human error and improving decision-making in resource management.

Accuracy Comparison: Manual vs Drone-Based Data Collection

Manual sampling in mining often provides highly localized and precise data points through direct human intervention, but it can be limited by human error and slower data acquisition rates. Drone-based mapping enhances accuracy by capturing extensive spatial data rapidly with high-resolution sensors, reducing inconsistencies caused by terrain variability and human factors. Combining drone-based geospatial data with ground-truth manual samples results in more robust and accurate mineral deposit modeling and resource estimation.

Efficiency and Time Consumption Analysis

Manual sampling in mining involves labor-intensive processes that often lead to slower data collection and increased human error, limiting efficiency. Drone-based mapping significantly reduces time consumption by capturing high-resolution aerial data over extensive areas quickly, enabling real-time analysis and decision-making. The integration of drone technology enhances operational efficiency by streamlining sampling workflows and minimizing downtime in mining explorations.

Cost Implications: Labor vs Technological Investment

Manual sampling in mining involves extensive labor costs due to the need for skilled personnel to collect and analyze samples on-site, often resulting in longer project timelines and higher safety risks. Drone-based mapping requires an upfront technological investment in high-resolution sensors and software but significantly reduces labor expenses and accelerates data collection across large areas. Over time, the cost efficiency of drones increases as they enable faster decision-making and minimize human exposure in hazardous mining environments.

Safety Considerations in Sampling Techniques

Manual sampling in mining exposes workers to hazards such as unstable terrain, heavy machinery, and limited visibility, increasing the risk of accidents and injuries. Drone-based mapping minimizes these risks by remotely capturing high-resolution data, enabling operators to assess mining sites without physical presence in dangerous areas. Employing drones enhances overall safety protocols by reducing human exposure to hazardous conditions during sampling operations.

Environmental Impact of Sampling Methods

Manual sampling in mining often results in localized environmental disturbance due to soil compaction and vegetation removal, whereas drone-based mapping minimizes ground impact by capturing high-resolution aerial data. Drone technology enables precise identification of mineral deposits, reducing the need for extensive physical sampling and preserving surrounding ecosystems. This shift toward drone-based methods supports sustainable mining practices by lowering habitat disruption and soil erosion risks.

Data Integration and Real-Time Decision Making

Manual sampling in mining offers high-accuracy localized data but is often time-consuming and lacks seamless integration with broader datasets, limiting real-time decision-making capabilities. Drone-based mapping provides extensive spatial coverage and rapid data collection, enabling continuous data integration through advanced software platforms for comprehensive mine site analysis. This integration facilitates real-time decision making by delivering up-to-date geospatial insights, enhancing operational efficiency and safety.

Future Trends: Automation and Smart Mining

Manual sampling in mining remains essential for precise material analysis but is increasingly augmented by drone-based mapping, which offers rapid, high-resolution spatial data collection. Future trends emphasize automation and smart mining technologies integrating drone data with AI-driven analytics to enhance resource estimation accuracy and operational efficiency. These advancements enable real-time decision-making, reduce human risk, and drive sustainable mining practices through optimized resource management.

Related Important Terms

Grab Sampling

Grab sampling in mining offers direct collection of ore or soil samples for precise compositional analysis, providing immediate, localized data critical for quality control. Drone-based mapping complements this by delivering extensive aerial mineral distribution maps, enhancing exploration efficiency and reducing human exposure to hazardous sites.

Channel Sampling

Channel sampling offers precise ore grade analysis by extracting continuous rock sections, but manual sampling is labor-intensive and prone to human error. Drone-based mapping enhances channel sampling by providing high-resolution spatial data and accelerating site surveys, improving accuracy and operational efficiency in mineral resource estimation.

Representative Subsampling

Manual sampling in mining offers direct control for collecting representative subsamples but is often limited by spatial coverage and human error, whereas drone-based mapping provides extensive, high-resolution spatial data enabling more precise and comprehensive subsampling strategies through advanced geospatial analytics. Integrating drone technology enhances the accuracy of ore body characterization by minimizing sampling bias and improving resource estimation models with multispectral and LiDAR data.

Sample Bias Correction

Manual sampling in mining often faces limitations in spatial coverage and introduces sample bias due to human error and inconsistent sampling density, impacting resource estimation accuracy. Drone-based mapping enables comprehensive geological data acquisition with high-resolution imagery and geospatial analysis, facilitating effective sample bias correction by integrating extensive spatial datasets and improving the representativeness of mineral deposit models.

Drone Photogrammetry

Drone photogrammetry offers high-resolution, georeferenced 3D models that significantly enhance spatial accuracy and data acquisition speed compared to manual sampling in mining operations. Leveraging UAV-mounted cameras, drone photogrammetry enables comprehensive volumetric analysis and rapid mine site mapping, reducing human error and improving safety while providing detailed terrain and stockpile measurements essential for operational planning.

UAV Point Cloud Generation

Manual sampling in mining provides localized data but often lacks comprehensive spatial coverage and efficiency compared to UAV point cloud generation, which creates detailed 3D maps using drone-based LiDAR or photogrammetry. UAVs enable rapid, high-resolution mapping of expansive mining sites, enhancing accuracy in volume estimation, terrain modeling, and mineral exploration.

Automated Flight Path Sampling

Automated flight path sampling in mining leverages drone-based mapping to systematically collect high-resolution spatial data, enhancing accuracy and reducing human error compared to manual sampling methods. This technology enables efficient coverage of large, complex terrains while minimizing operational time and safety risks inherent in traditional manual sampling practices.

Geospatial Orthomosaic Mapping

Manual sampling in mining provides localized, ground-truth data but is time-consuming and limited in spatial coverage, whereas drone-based geospatial orthomosaic mapping offers high-resolution, comprehensive aerial imagery that enables precise mineral deposit analysis and terrain modeling over large areas efficiently. Orthomosaic maps generated by drones integrate georeferenced images to create accurate, scalable maps essential for resource estimation, site monitoring, and operational planning in mining.

Real-Time Sample Geotagging

Manual sampling in mining often suffers from delayed data entry and imprecise location records, while drone-based mapping offers real-time sample geotagging with high accuracy, enhancing spatial data integration and decision-making. Utilizing drones equipped with GPS and advanced sensors allows instant capture and geolocation of samples, significantly improving workflow efficiency and resource management.

AI-driven Anomaly Detection

AI-driven anomaly detection enhances manual sampling by identifying irregularities in geological data with higher precision and speed, reducing human error and operational costs. Drone-based mapping integrated with AI algorithms provides comprehensive spatial analysis, enabling early detection of mineral deposits and fault lines beyond the reach of traditional manual methods.

Manual sampling vs Drone-based mapping Infographic

industrydif.com

industrydif.com