Heap leach pads are designed for cost-effective extraction of valuable metals by stacking ore in large heaps, allowing a leaching solution to percolate through and dissolve target minerals. Geomembrane-lined heaps incorporate synthetic liners beneath the ore to prevent leachate seepage, enhancing environmental safety and reducing groundwater contamination risks. The choice between traditional heap leach pads and geomembrane-lined heaps depends on site-specific environmental regulations, ore characteristics, and economic considerations.

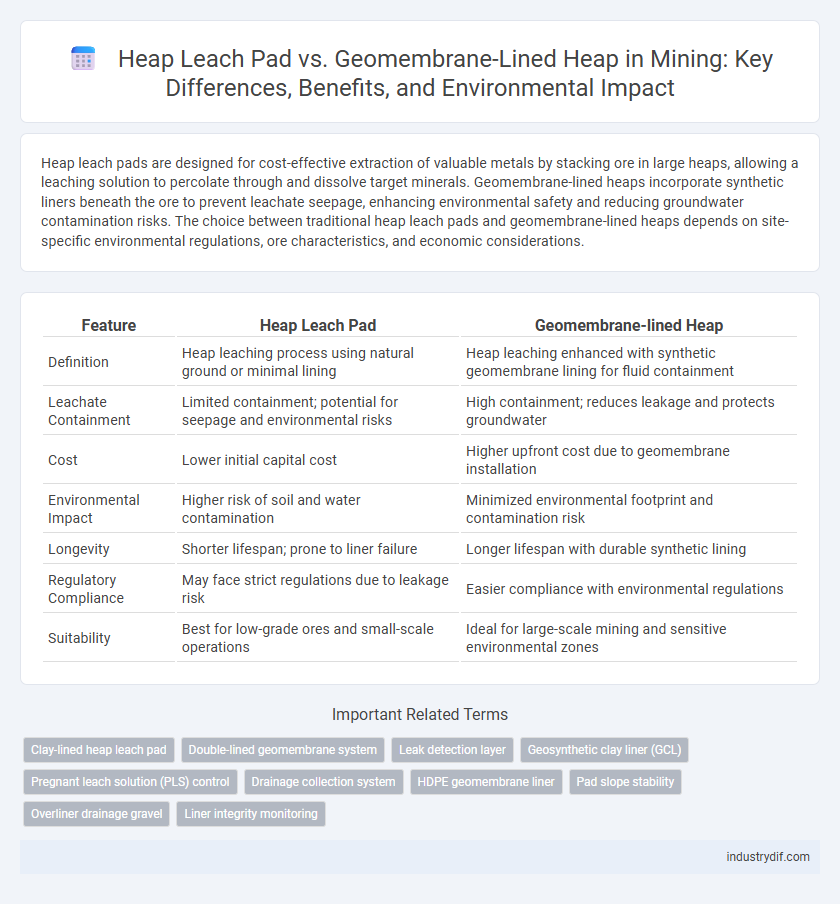

Table of Comparison

| Feature | Heap Leach Pad | Geomembrane-lined Heap |

|---|---|---|

| Definition | Heap leaching process using natural ground or minimal lining | Heap leaching enhanced with synthetic geomembrane lining for fluid containment |

| Leachate Containment | Limited containment; potential for seepage and environmental risks | High containment; reduces leakage and protects groundwater |

| Cost | Lower initial capital cost | Higher upfront cost due to geomembrane installation |

| Environmental Impact | Higher risk of soil and water contamination | Minimized environmental footprint and contamination risk |

| Longevity | Shorter lifespan; prone to liner failure | Longer lifespan with durable synthetic lining |

| Regulatory Compliance | May face strict regulations due to leakage risk | Easier compliance with environmental regulations |

| Suitability | Best for low-grade ores and small-scale operations | Ideal for large-scale mining and sensitive environmental zones |

Introduction to Heap Leach Pads

Heap leach pads are engineered facilities designed to extract valuable metals from low-grade ores by stacking crushed ore and applying leaching solutions. These pads typically feature a single or multiple layers of compacted materials, such as clay or synthetic liners, to prevent environmental contamination by containing the leachate. Geomembrane-lined heap leach pads use advanced synthetic liners to enhance impermeability, reduce seepage risks, and improve operational efficiency compared to traditional pad designs.

Overview of Geomembrane-Lined Heaps

Geomembrane-lined heap leach pads utilize synthetic liners to prevent solution leakage and protect underlying soil and groundwater from contamination. These liners, typically made of high-density polyethylene (HDPE), provide enhanced impermeability compared to traditional unlined or natural soil heaps. Their design supports greater environmental safety and operational control, improving solution recovery efficiency in mining operations.

Key Differences Between Conventional and Lined Pads

Heap leach pads utilize natural soil or unlined surfaces, allowing process solutions to percolate through ore but posing higher risks of environmental contamination. Geomembrane-lined heap leach pads incorporate synthetic liners, such as high-density polyethylene (HDPE), that provide a containment barrier to prevent leachate leakage and protect groundwater. The key differences include leakage prevention, environmental safety, construction cost, and operational longevity, with geomembrane-lined pads offering enhanced containment and regulatory compliance at a higher initial investment.

Environmental Considerations in Heap Leaching

Heap leach pads without geomembrane liners pose a significant risk of contaminant leakage into surrounding soil and groundwater, leading to environmental degradation and increased remediation costs. Geomembrane-lined heaps offer superior containment, minimizing the percolation of toxic leachates, which protects aquifers and reduces long-term ecological damage. Careful selection and maintenance of liners are critical to prevent liner failure and ensure sustainable heap leaching operations with minimal environmental impact.

Material Selection for Heap Leach Pads

Material selection for heap leach pads significantly influences the efficiency and environmental safety of mining operations. Geomembrane-lined heaps require high-density polyethylene (HDPE) liners due to their chemical resistance and durability, minimizing leachate seepage and protecting groundwater. In contrast, unlined heap leach pads rely heavily on natural soil permeability, often necessitating the use of clay or compacted soils with low hydraulic conductivity to reduce infiltration and contamination risks.

Cost Comparison: Traditional vs Geomembrane-Lined Systems

Heap leach pads offer lower initial construction costs but higher long-term environmental management expenses due to potential seepage and contamination, whereas geomembrane-lined heap leach systems involve higher upfront costs driven by materials like HDPE liners and installation complexities, significantly reducing leakage risk and remediation costs. The total cost of ownership for geomembrane-lined systems is often justified by improved containment efficiency, regulatory compliance, and reduced environmental liabilities. Mining operations focused on cost-effective reclamation and sustainability increasingly favor geomembrane-lined solutions despite their higher capital investment.

Performance and Longevity of Leach Pads

Heap leach pads without geomembrane liners often experience higher permeability, leading to increased leakage risks and environmental contamination, which reduces overall performance and longevity. Geomembrane-lined heap pads provide superior containment by drastically minimizing seepage and enhancing solution recovery rates, thereby extending the operational lifespan of the leach facility. The durability of geomembrane materials under varying climatic and chemical conditions directly contributes to sustained leach efficiency and reduced maintenance costs over time.

Regulatory Compliance and Heap Leach Design

Heap leach pads with geomembrane liners enhance regulatory compliance by preventing toxic leachate from contaminating groundwater, meeting stringent environmental standards. Geomembrane-lined heaps optimize heap leach design through improved containment, allowing for safer and more efficient metal recovery processes. These engineered liners reduce operational risks and ensure adherence to environmental permits, critical for sustainable mining practices.

Risk Mitigation in Heap Leach Operations

Heap leach pads without geomembrane liners present higher risks of cyanide and heavy metal contamination to surrounding soil and groundwater, demanding rigorous monitoring and containment strategies. Geomembrane-lined heaps significantly reduce seepage and environmental hazards by providing a durable barrier that prevents toxic solution leakage and facilitates regulatory compliance. Incorporating geomembrane liners enhances long-term stability and minimizes remediation costs, making them a preferred choice for risk mitigation in large-scale heap leach operations.

Future Trends in Heap Leach Pad Technology

Future trends in heap leach pad technology emphasize enhanced environmental protection through advanced geomembrane liners that minimize permeability and prevent leakage of toxic solutions. Innovations in sensor integration and real-time monitoring systems improve operational efficiency and early detection of structural integrity issues. Sustainable practices and cost-effective materials are being developed to reduce ecological impact while optimizing metal recovery rates in heap leaching operations.

Related Important Terms

Clay-lined heap leach pad

Clay-lined heap leach pads offer a natural, low-permeability barrier that reduces contaminant leakage by enhancing containment compared to geomembrane-lined heaps, which rely on synthetic liners for impermeability. While clay liners provide cost-effective environmental protection and durability, they may require thicker installations and maintenance to prevent cracking and ensure consistent leachate management.

Double-lined geomembrane system

Double-lined geomembrane heap leach pads offer enhanced environmental protection by preventing leachate leakage through a secondary impermeable barrier, reducing the risk of soil and groundwater contamination compared to conventional single-lined systems. This double containment system significantly improves the integrity and lifespan of heap leach operations, ensuring compliance with stringent environmental regulations and minimizing potential liability.

Leak detection layer

Heap leach pads with geomembrane liners incorporate a leak detection layer designed to identify and contain seepage, minimizing environmental contamination compared to traditional unlined pads. This leak detection layer enhances fluid monitoring efficiency by providing an early warning system, ensuring the integrity of the heap leach process and protecting surrounding soil and groundwater.

Geosynthetic clay liner (GCL)

Geosynthetic clay liners (GCLs) integrated within geomembrane-lined heap leach pads provide enhanced containment by combining geosynthetic impermeability with the swelling properties of bentonite clay, significantly reducing the risk of leachate migration compared to traditional heap leach pads. The layered design of GCLs offers superior hydraulic conductivity control and chemical resistance, ensuring long-term environmental protection in mining operations.

Pregnant leach solution (PLS) control

Heap leach pads use natural or compacted soil layers to allow percolation but risk PLS seepage, whereas geomembrane-lined heaps incorporate synthetic liners that provide superior containment and minimize PLS leakage into the surrounding environment. Effective PLS control is critical to prevent groundwater contamination, making geomembrane-lined systems the preferred choice for environmental compliance and operational efficiency in mining heap leaching.

Drainage collection system

Heap leach pads rely on natural soil permeability for drainage collection systems, while geomembrane-lined heaps utilize impermeable synthetic liners to prevent seepage and effectively channel leachate into engineered collection networks. This enhanced control in geomembrane-lined heaps reduces environmental contamination risks and improves leachate recovery efficiency.

HDPE geomembrane liner

HDPE geomembrane liners in heap leach pads provide superior chemical resistance and impermeability, significantly reducing the risk of toxic leachate infiltration into surrounding soil and groundwater. Their durability under extreme environmental conditions outperforms traditional unlined heap leach pads, ensuring enhanced environmental protection and operational efficiency.

Pad slope stability

Heap leach pad slope stability depends significantly on the presence of a geomembrane liner, which enhances structural integrity by preventing fluid migration and reducing seepage-induced instability. Unlined heap leach pads are more susceptible to slope failures due to fluid infiltration weakening the base, whereas geomembrane-lined pads provide critical containment and support, thereby improving overall slope stability in mining operations.

Overliner drainage gravel

Overliner drainage gravel plays a critical role in both heap leach pads and geomembrane-lined heaps by enhancing permeability and facilitating efficient leachate collection, thereby preventing fluid buildup that can compromise pad stability. In geomembrane-lined heaps, the drainage gravel layer not only supports structural integrity but also protects the liner from puncture and hydraulic pressure, optimizing the heap leach recovery process.

Liner integrity monitoring

Heap leach pads with geomembrane liners require advanced liner integrity monitoring systems such as electrical leak location surveys and automated sensor networks to promptly detect breaches and prevent hazardous fluid leakage. Continuous monitoring technologies improve the reliability of geomembrane-lined heaps by enabling early intervention, thereby minimizing environmental risks and ensuring compliance with mining regulatory standards.

Heap leach pad vs Geomembrane-lined heap Infographic

industrydif.com

industrydif.com