Heap leaching and glycine leaching are two effective techniques for extracting valuable metals from low-grade ores. Heap leaching involves stacking crushed ore and applying a leaching solution, typically cyanide, to dissolve metals over time, making it cost-efficient for large-scale operations. Glycine leaching offers an eco-friendly alternative by using a biodegradable amino acid solution, reducing environmental risks and improving metal recovery from refractory ores.

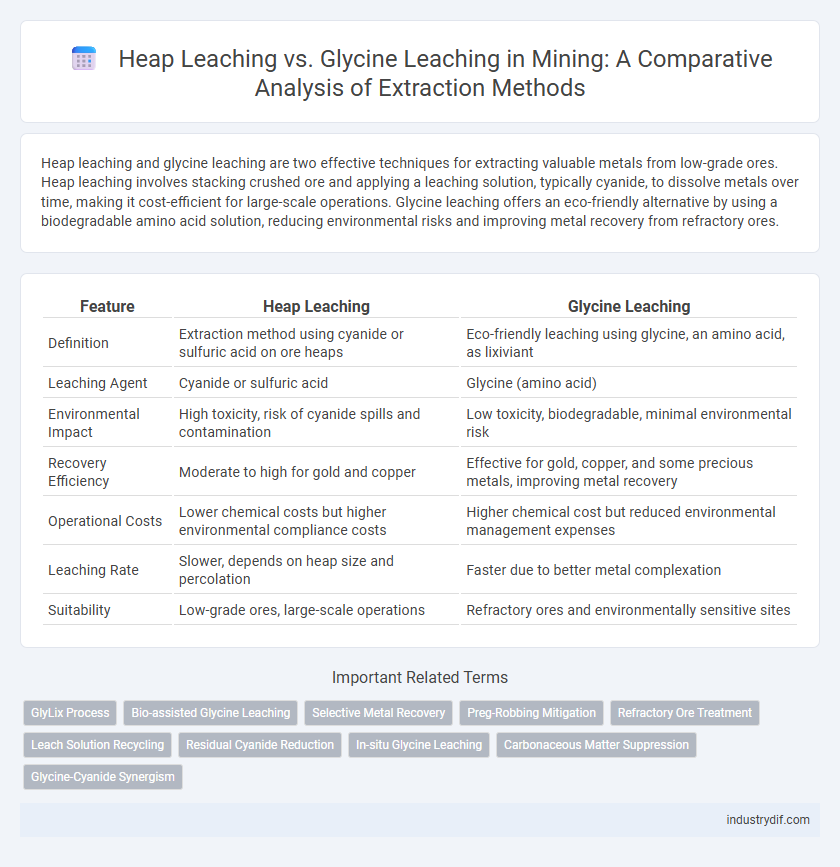

Table of Comparison

| Feature | Heap Leaching | Glycine Leaching |

|---|---|---|

| Definition | Extraction method using cyanide or sulfuric acid on ore heaps | Eco-friendly leaching using glycine, an amino acid, as lixiviant |

| Leaching Agent | Cyanide or sulfuric acid | Glycine (amino acid) |

| Environmental Impact | High toxicity, risk of cyanide spills and contamination | Low toxicity, biodegradable, minimal environmental risk |

| Recovery Efficiency | Moderate to high for gold and copper | Effective for gold, copper, and some precious metals, improving metal recovery |

| Operational Costs | Lower chemical costs but higher environmental compliance costs | Higher chemical cost but reduced environmental management expenses |

| Leaching Rate | Slower, depends on heap size and percolation | Faster due to better metal complexation |

| Suitability | Low-grade ores, large-scale operations | Refractory ores and environmentally sensitive sites |

Overview of Heap Leaching and Glycine Leaching

Heap leaching is a widely used mining technique that involves stacking ore into heaps and applying a chemical solution, typically cyanide, to extract valuable metals such as gold and copper. Glycine leaching is an innovative environmentally friendly alternative that utilizes the amino acid glycine as a lixiviant, offering lower toxicity and enhanced metal recovery, especially from complex or oxide ores. Both methods optimize metal extraction efficiency but differ significantly in chemical agents and environmental impact.

Key Differences in Chemical Processes

Heap leaching relies on sulfuric acid to dissolve metal ores through an oxidative reaction, effectively extracting copper and gold from sulfide and oxide ores. Glycine leaching uses the amino acid glycine in an alkaline solution to form stable metal complexes, enabling selective extraction of metals like gold and copper with lower environmental impact. The key difference lies in the chemical mechanisms: heap leaching promotes acid-based oxidative dissolution, while glycine leaching operates via complexation under mild alkaline conditions, improving selectivity and reducing acid use.

Ore Suitability for Each Leaching Method

Heap leaching is highly effective for low-grade oxide ores and sulfide ores with high permeability, allowing efficient percolation of the leach solution through large ore piles. Glycine leaching is better suited for ores rich in copper, particularly for complex sulfide minerals and bioleaching applications, as glycine forms stable complexes enhancing metal recovery under mild conditions. Selection depends on ore mineralogy, particle size, and economic factors, with heap leaching favored for bulk processing and glycine leaching preferred for selective extraction of precious or base metals.

Environmental Impact Comparison

Heap leaching and glycine leaching differ significantly in environmental impact, with glycine leaching offering a more eco-friendly alternative due to its biodegradable and less toxic nature. Heap leaching often involves cyanide, which poses substantial risks of soil and water contamination, while glycine, an amino acid, reduces chemical hazards and improves sustainability in metal extraction processes. The adoption of glycine leaching minimizes hazardous waste production and enhances compliance with environmental regulations, making it a preferable choice for greener mining operations.

Extraction Efficiency and Metal Recovery Rates

Heap leaching typically achieves metal recovery rates of 60-80% for gold and copper, but glycine leaching demonstrates higher extraction efficiency with recovery rates exceeding 85%, especially in oxide and secondary sulfide ores. Glycine leaching operates effectively at lower cyanide concentrations, reducing environmental impact while enhancing metal dissolution kinetics compared to traditional heap leaching. This method also shows superior selectivity and metal recovery in complex ores, optimizing overall extraction performance in mining operations.

Operational Costs and Economic Considerations

Heap leaching typically incurs lower capital expenditure but higher operational costs due to longer processing times and larger reagent volumes, while glycine leaching, although requiring higher initial investment in specialized reagents, offers faster metal recovery and reduced environmental liabilities. The economic considerations favor glycine leaching in environmentally sensitive regions due to its biodegradable nature and decreased waste management expenses. Operational costs in heap leaching rise with scale and ore grade variability, making glycine leaching more cost-effective for low-grade or complex ores.

Scalability and Commercial Applications

Heap leaching demonstrates strong scalability in extracting metals from low-grade ores and is widely adopted in large-scale commercial mining due to its cost-effectiveness and simplicity. Glycine leaching, an emerging technology, offers greater environmental benefits and improved metal recovery from complex ores but currently faces scalability challenges limiting its commercial use. Ongoing advancements in glycine leaching processes aim to enhance throughput and reduce operational costs, positioning it as a promising alternative for future commercial mining applications.

Reagent Consumption and Recyclability

Heap leaching typically involves higher reagent consumption due to cyanide use, whereas glycine leaching significantly reduces chemical input by utilizing an amino acid-based reagent system, enhancing environmental sustainability. Glycine leaching offers better reagent recyclability, as the organic nature of glycine allows for easier recovery and reuse compared to conventional cyanide-based heap leaching solutions. Lower reagent consumption and improved recyclability in glycine leaching contribute to reduced operational costs and minimized environmental impact in mineral extraction processes.

Regulatory and Safety Aspects

Heap leaching with cyanide is highly regulated due to the toxicity and environmental risks associated with cyanide spills and groundwater contamination, requiring stringent monitoring and containment measures. Glycine leaching presents a safer alternative by using a biodegradable, non-toxic lixiviant that reduces regulatory burdens related to hazardous chemical handling and mitigates risks to worker health and ecosystems. Regulatory frameworks increasingly favor glycine leaching as part of sustainable mining practices, emphasizing lower environmental impact and enhanced operational safety.

Future Trends in Leaching Technologies

Emerging advancements in heap leaching and glycine leaching focus on enhancing metal recovery rates while minimizing environmental impact, particularly through bioleaching additives and pH optimization to target low-grade ores. Research in glycine leaching emphasizes its biodegradability and its efficacy in extracting gold and copper from sulfide minerals, positioning it as a sustainable alternative to traditional cyanide processes. Future trends involve integrating real-time monitoring with automated leach pad management systems to optimize lixiviant consumption and reduce operational costs across mining operations.

Related Important Terms

GlyLix Process

The GlyLix process, an innovative glycine leaching method, enhances gold recovery by utilizing a biodegradable amino acid lixiviant, offering a more environmentally sustainable alternative to traditional cyanide heap leaching with reduced toxicity and lower reagent consumption. This process achieves higher selectivity and efficiency in extracting precious metals from refractory ores, significantly decreasing environmental impact and operational costs compared to conventional heap leaching.

Bio-assisted Glycine Leaching

Bio-assisted glycine leaching enhances metal recovery from low-grade ores by utilizing glycine as a biodegradable lixiviant coupled with microbial activity to increase dissolution rates of valuable metals like copper and gold. Compared to traditional heap leaching, this method offers improved environmental sustainability, faster kinetics, and higher selectivity, reducing toxic chemical usage and minimizing ecological impact.

Selective Metal Recovery

Heap leaching offers cost-effective extraction of low-grade ores but often results in lower selectivity for valuable metals, whereas glycine leaching enhances selective metal recovery by leveraging amino acid complexes to target specific metals like copper and gold with reduced environmental impact. Glycine leaching's ability to operate in mild pH conditions improves metal purity and reduces co-extraction of impurities compared to traditional cyanide heap leaching processes.

Preg-Robbing Mitigation

Heap leaching with glycine solutions improves preg-robbing mitigation by enhancing gold recovery through selective adsorption reduction on carbonaceous ores, outperforming traditional cyanide heap leaching methods prone to preg-robbing losses. The use of glycine, a biodegradable and environmentally friendly lixiviant, stabilizes gold complexes and minimizes adsorption onto preg-robbing minerals, thereby increasing extraction efficiency in refractory gold deposits.

Refractory Ore Treatment

Heap leaching and glycine leaching offer distinct advantages for refractory ore treatment, with heap leaching being cost-effective for large-scale operations despite lower extraction rates, while glycine leaching provides environmentally friendly, selective gold recovery with improved metal dissolution in complex sulfide ores. Glycine leaching enhances gold extraction from refractory ores by reducing cyanide consumption and minimizing environmental risks, making it a promising alternative for sustainable mining practices.

Leach Solution Recycling

Heap leaching offers limited leach solution recycling due to solution dilution and nutrient depletion, resulting in increased water and reagent consumption. Glycine leaching enables superior leach solution recycling by maintaining stable pH and complex formation, minimizing reagent loss and reducing overall operational costs.

Residual Cyanide Reduction

Heap leaching with cyanide often results in significant residual cyanide levels, posing environmental risks and requiring extensive detoxification processes; in contrast, glycine leaching offers a less toxic alternative with substantially lower residual cyanide concentrations, enhancing sustainability and reducing chemical remediation costs. Studies indicate glycine leaching can decrease residual cyanide by up to 90%, making it a preferred method for environmentally responsible gold extraction.

In-situ Glycine Leaching

In-situ glycine leaching offers a more environmentally friendly alternative to traditional heap leaching by utilizing the biodegradable amino acid glycine to solubilize metals directly within the ore body, reducing the need for extensive ore excavation. This method enhances metal recovery efficiency in low-grade ores while minimizing acid consumption and mitigating the risks of acid mine drainage commonly associated with sulfuric acid-based heap leaching processes.

Carbonaceous Matter Suppression

Heap leaching with glycine demonstrates superior carbonaceous matter suppression compared to traditional cyanide methods, enabling more efficient gold recovery from refractory ores. Glycine's selective chelation reduces gold losses by minimizing cyanide consumption and preventing gold entrapment within carbonaceous materials.

Glycine-Cyanide Synergism

Glycine leaching offers a sustainable alternative to cyanide in gold extraction by enhancing metal recovery through glycine-cyanide synergism, which improves gold solubilization rates and reduces environmental toxicity. This synergistic interaction facilitates more efficient heap leaching operations by combining the strong complexation properties of cyanide with the biodegradable and less toxic glycine, leading to higher gold recovery and lower cyanide consumption.

Heap Leaching vs Glycine Leaching Infographic

industrydif.com

industrydif.com