Sluicing uses water to separate valuable minerals from sediment by flowing it through a sluice box, exploiting the density differences of particles. Phytomining involves growing plants that absorb heavy metals from the soil, which are then harvested and processed to extract the metals. While sluicing relies on mechanical separation techniques in mining, phytomining offers an environmentally friendly alternative by utilizing natural biological processes to recover metals.

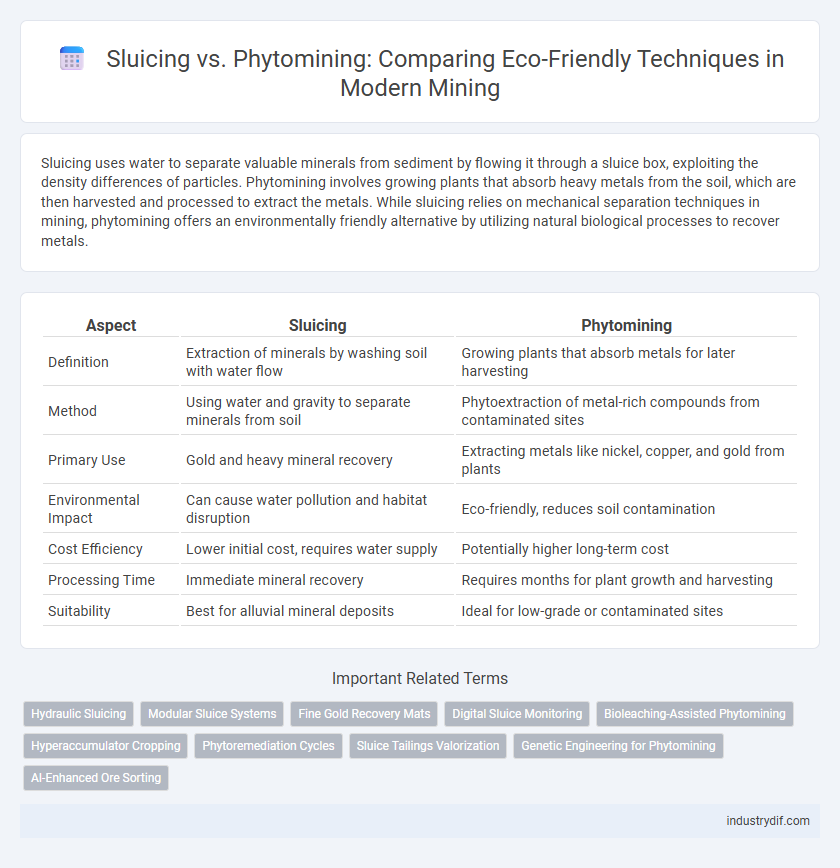

Table of Comparison

| Aspect | Sluicing | Phytomining |

|---|---|---|

| Definition | Extraction of minerals by washing soil with water flow | Growing plants that absorb metals for later harvesting |

| Method | Using water and gravity to separate minerals from soil | Phytoextraction of metal-rich compounds from contaminated sites |

| Primary Use | Gold and heavy mineral recovery | Extracting metals like nickel, copper, and gold from plants |

| Environmental Impact | Can cause water pollution and habitat disruption | Eco-friendly, reduces soil contamination |

| Cost Efficiency | Lower initial cost, requires water supply | Potentially higher long-term cost |

| Processing Time | Immediate mineral recovery | Requires months for plant growth and harvesting |

| Suitability | Best for alluvial mineral deposits | Ideal for low-grade or contaminated sites |

Introduction to Sluicing and Phytomining

Sluicing involves washing sediment through a sluice box to separate heavier minerals like gold from lighter materials using water flow and gravity. Phytomining uses specific plants to extract valuable metals such as nickel or copper from soil, accumulating these metals in their biomass for later harvesting and processing. Both methods offer environmentally friendly alternatives to traditional mining by reducing landscape disruption and chemical use.

Overview of Sluicing in Mining Operations

Sluicing in mining operations involves using water to separate valuable minerals from sediment by allowing heavier particles to settle in a sluice box, enhancing efficiency in gold and gemstone extraction. This technique relies on gravity and water flow to concentrate minerals, making it cost-effective for placer mining in riverbeds and alluvial deposits. Sluicing minimizes environmental impact compared to traditional mining methods by reducing the need for chemical processing.

Principles and Techniques of Phytomining

Phytomining utilizes hyperaccumulator plants to extract valuable metals like nickel and gold from soil by absorbing and concentrating them in their biomass, which is then harvested and processed to recover the metals. This technique relies on the principles of bioaccumulation and phytoremediation to recover metals from low-grade ores or contaminated soils, offering an environmentally friendly alternative to traditional mining methods such as sluicing. Phytomining involves growing specific plants on metal-rich soils, harvesting the plant material, and incinerating it to produce a metal-rich ash for extraction, while sluicing depends on mechanical separation of metals from sediments through water flow and gravity.

Comparative Environmental Impact

Sluicing involves using water to separate valuable minerals from ore, leading to significant water consumption and sediment disruption, which can harm aquatic ecosystems. Phytomining employs hyperaccumulator plants to extract metals from soil, reducing habitat destruction and minimizing chemical runoff compared to traditional methods. Overall, phytomining presents a more sustainable and lower-impact alternative by enhancing soil health and reducing water pollution risks inherent in sluicing.

Resource Recovery Efficiency

Sluicing involves the mechanical separation of minerals from sediments using water flow, offering moderate resource recovery efficiency with high operational water use. Phytomining utilizes hyperaccumulator plants to extract valuable metals from soil, providing eco-friendly recovery with potential for regenerating low-grade ores but slower metal accumulation rates. Resource recovery efficiency in phytomining can surpass traditional sluicing for certain metals like nickel and cadmium, especially in contaminated or low-grade sites where conventional methods are less effective.

Equipment and Technology Requirements

Sluicing requires specialized equipment such as sluice boxes, water pumps, and riffles designed to separate heavy minerals from sediment using flowing water, relying on gravity concentration technology. Phytomining demands advanced agricultural technology, including genetically engineered hyperaccumulator plants, specialized harvesting machinery, and processing units to extract metals from biomass through bioleaching or pyroprocessing. While sluicing emphasizes mechanical and hydraulic equipment for sediment processing, phytomining integrates biotechnological advancements with conventional agricultural and metallurgical tools.

Economic Viability and Cost Analysis

Sluicing offers lower initial capital investment but incurs higher labor and water management costs compared to phytomining, which involves slower metal recovery rates but benefits from lower operational expenses and environmental remediation savings. Phytomining, through the use of hyperaccumulator plants, reduces the need for extensive infrastructure and chemical inputs, enhancing its economic viability in marginal ore deposits or contaminated sites. Cost analysis reveals sluicing achieves quicker returns in high-grade deposits, whereas phytomining provides a sustainable, lower-cost alternative suited for long-term metal extraction with reduced ecological impact.

Regulatory and Safety Considerations

Sluicing involves the use of water to separate valuable minerals from sediment, requiring strict adherence to water management regulations to prevent contamination and erosion. Phytomining employs hyperaccumulator plants to extract metals from soil, necessitating compliance with environmental guidelines to manage potential bioaccumulation risks and disposal of contaminated biomass. Both methods demand rigorous safety protocols to protect workers from exposure to hazardous materials and ensure sustainable mining practices.

Applications and Limitations in Modern Mining

Sluicing is widely used in alluvial gold mining to separate heavy minerals by water flow, offering efficient extraction in high-volume operations but limited by water availability and sediment composition. Phytomining involves cultivating hyperaccumulator plants to extract valuable metals like nickel and gold from low-grade ores and contaminated soils, providing an eco-friendly alternative with slower metal recovery rates and specific plant growth requirements. Both techniques complement modern mining by addressing resource scarcity and environmental concerns, yet their effectiveness depends on site-specific geological and ecological conditions.

Future Prospects: Sluicing vs. Phytomining

Sluicing remains a cost-effective mining technique with potential advancements in mechanization and automation increasing its efficiency and environmental sustainability. Phytomining offers a promising future as a green technology that can extract valuable metals from low-grade ores and contaminated soils while rehabilitating ecosystems. Integrating phytomining with sluicing could optimize resource recovery by combining traditional mechanical methods with innovative, eco-friendly metal extraction processes.

Related Important Terms

Hydraulic Sluicing

Hydraulic sluicing uses high-pressure water jets to dislodge and separate minerals from sediment, enabling efficient gold recovery from alluvial deposits. This method contrasts with phytomining, which employs hyperaccumulator plants to absorb metals, making hydraulic sluicing more immediate in mineral extraction but requiring significant water resources and environmental management.

Modular Sluice Systems

Modular sluice systems enhance traditional sluicing by offering scalable, efficient separation of heavy minerals such as gold through adjustable riffles and water flow, optimizing recovery rates in small to medium-scale operations. Unlike phytomining, which relies on hyperaccumulator plants to extract metals from soil over extended periods, modular sluice systems provide immediate and reusable infrastructure designed for rapid mineral concentration and easy deployment in remote mining sites.

Fine Gold Recovery Mats

Sluicing uses gravity separation techniques with fine gold recovery mats to capture minute particles from water or slurry efficiently, enhancing gold yield in placer mining operations. Phytomining leverages hyperaccumulator plants to extract gold from contaminated soils, but fine gold recovery mats remain essential to refine and concentrate gold particles during subsequent processing stages.

Digital Sluice Monitoring

Digital sluice monitoring enhances traditional sluicing by providing real-time data analytics on particle separation efficiency and water flow rates, enabling optimized recovery of valuable minerals such as gold. This technology contrasts with phytomining, which leverages hyperaccumulator plants to extract metals, offering a complementary approach where digital sluice systems prioritize immediate mineral recovery while phytomining supports long-term environmental sustainability.

Bioleaching-Assisted Phytomining

Bioleaching-assisted phytomining enhances metal recovery by exploiting microorganisms to solubilize metals from low-grade ores or contaminated soils, which plants then uptake and concentrate in their biomass for harvest. This technique combines biological leaching efficiency with phytomining's eco-friendly extraction, offering a sustainable alternative to traditional sluicing methods that rely on mechanical separation of ore particles.

Hyperaccumulator Cropping

Hyperaccumulator cropping in phytomining exploits plants capable of absorbing high concentrations of metals from soil, enabling eco-friendly recovery of valuable elements like nickel and cobalt. Sluicing, in contrast, relies on water currents to separate heavier metal particles from sediments, offering a mechanical extraction method with less biological impact.

Phytoremediation Cycles

Phytomining uses hyperaccumulator plants to extract valuable metals from contaminated soils through multiple phytoremediation cycles, enabling metal recovery without soil excavation. Unlike sluicing, which relies on water separation of minerals, phytomining promotes sustainable metal extraction while gradually restoring soil health across successive plant growth cycles.

Sluice Tailings Valorization

Sluicing tailings valorization enhances metal recovery by reprocessing sediment materials through water-channel sluices, effectively concentrating valuable minerals often overlooked in initial extraction. Phytomining, in contrast, uses hyperaccumulator plants to absorb metals from soil for subsequent harvesting, but sluicing offers higher throughput and immediate recovery from existing tailings.

Genetic Engineering for Phytomining

Genetic engineering enhances phytomining by modifying plants to accumulate higher concentrations of target metals from contaminated soils, thus increasing metal yield and extraction efficiency compared to traditional sluicing methods that rely on physical sediment separation. Engineered hyperaccumulator plants optimize metal uptake and tolerance, making phytomining a sustainable alternative to sluicing's environmentally disruptive processes.

AI-Enhanced Ore Sorting

AI-enhanced ore sorting improves sluicing efficiency by accurately separating valuable minerals from waste, reducing the amount of material processed and lowering operational costs. In contrast, phytomining, which uses hyperaccumulator plants to extract metals, benefits less directly from AI sorting but relies on precise identification of metal-rich biomass to optimize metal recovery.

Sluicing vs Phytomining Infographic

industrydif.com

industrydif.com