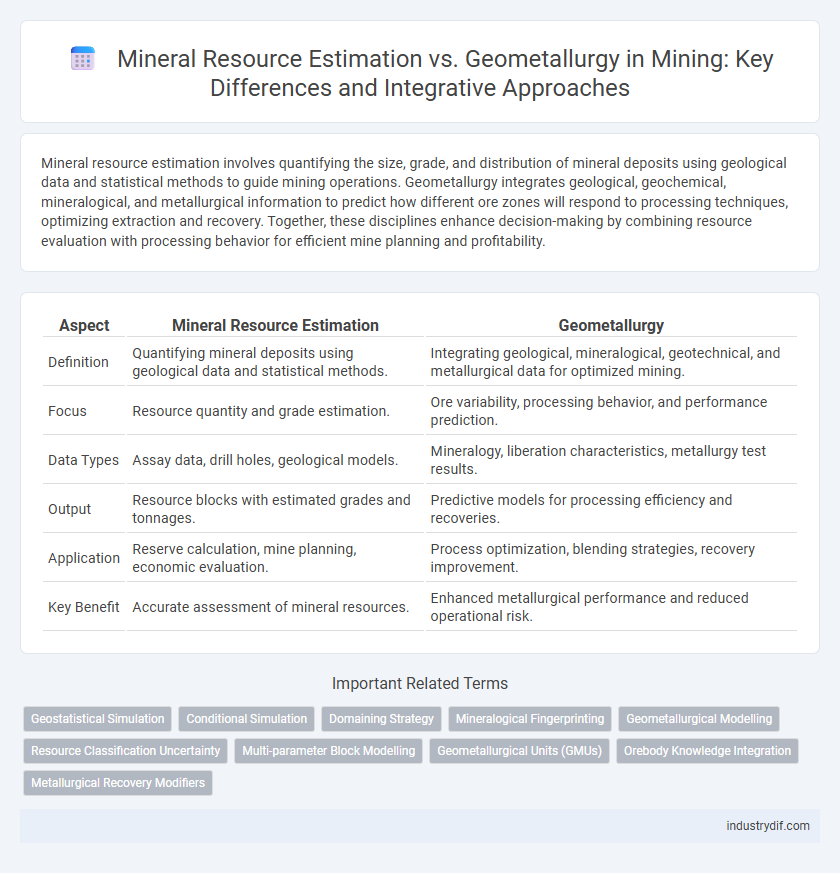

Mineral resource estimation involves quantifying the size, grade, and distribution of mineral deposits using geological data and statistical methods to guide mining operations. Geometallurgy integrates geological, geochemical, mineralogical, and metallurgical information to predict how different ore zones will respond to processing techniques, optimizing extraction and recovery. Together, these disciplines enhance decision-making by combining resource evaluation with processing behavior for efficient mine planning and profitability.

Table of Comparison

| Aspect | Mineral Resource Estimation | Geometallurgy |

|---|---|---|

| Definition | Quantifying mineral deposits using geological data and statistical methods. | Integrating geological, mineralogical, geotechnical, and metallurgical data for optimized mining. |

| Focus | Resource quantity and grade estimation. | Ore variability, processing behavior, and performance prediction. |

| Data Types | Assay data, drill holes, geological models. | Mineralogy, liberation characteristics, metallurgy test results. |

| Output | Resource blocks with estimated grades and tonnages. | Predictive models for processing efficiency and recoveries. |

| Application | Reserve calculation, mine planning, economic evaluation. | Process optimization, blending strategies, recovery improvement. |

| Key Benefit | Accurate assessment of mineral resources. | Enhanced metallurgical performance and reduced operational risk. |

Defining Mineral Resource Estimation and Geometallurgy

Mineral resource estimation involves quantifying the quantity and quality of minerals within a deposit using geological data, sampling, and statistical modeling to support mine planning and economic evaluation. Geometallurgy integrates geological, mineralogical, and metallurgical information to predict ore processing behavior and optimize beneficiation, blending, and extraction processes. Both disciplines are critical for improving the accuracy of resource valuation and operational efficiency in mining projects.

Core Objectives: Resource Estimation vs Geometallurgical Analysis

Mineral resource estimation focuses on quantifying the size, grade, and spatial distribution of mineral deposits to support mine planning and economic evaluation. Geometallurgical analysis integrates geological, mineralogical, and metallurgical data to predict ore processing behavior, enhancing orebody characterization and optimizing extraction techniques. Core objectives of resource estimation determine ore tonnage and quality, while geometallurgy aims to improve processing efficiency and recovery rates through detailed ore variability assessment.

Key Data Inputs for Each Discipline

Mineral resource estimation primarily relies on geological data such as drill hole assays, lithology, and structural mapping to quantify the grade and tonnage of ore bodies. Geometallurgy integrates metallurgical test results, mineralogy, and geochemical data alongside geological information to predict ore processing behavior and optimize extraction methods. Key data inputs for resource estimation emphasize spatial distribution and grade continuity, while geometallurgy requires detailed mineral characterization and process response indicators.

Geological Modeling Approaches

Mineral resource estimation relies on spatial statistical methods such as geostatistics and block modeling to quantify ore tonnage and grade distribution within geological boundaries. Geometallurgy integrates geological, mineralogical, and metallurgical data to create predictive models that assess ore processing performance and variability. Geological modeling approaches in mineral resource estimation typically focus on defining orebody geometry, while geometallurgy emphasizes linking geological heterogeneity to metallurgical behavior for optimized mining and processing strategies.

Integration of Sampling and Assay Data

Mineral resource estimation relies on geostatistical analysis of sampling and assay data to quantify ore grades and spatial distribution, enabling accurate resource modeling. Geometallurgy integrates these data with mineralogical and metallurgical properties to predict processing behavior and optimize mine planning. Effective integration of sampling and assay data enhances both resource delineation and process recovery predictions, driving improved operational decision-making.

Variability and Spatial Analysis Techniques

Mineral resource estimation relies heavily on geostatistical methods such as kriging and inverse distance weighting to model ore grade variability and quantify uncertainties across spatial domains. Geometallurgy integrates mineralogical and metallurgical variability with spatial analysis techniques like 3D geological modeling and geostatistical simulation to optimize ore processing and predict metallurgical performance. Both disciplines use spatial data analysis, but geometallurgy uniquely combines variability in mineralogy, texture, and chemistry to enhance predictive accuracy in extraction and processing workflows.

Impact on Mine Planning and Optimization

Mineral resource estimation provides quantitative data on ore grade and distribution essential for defining mine reserves, directly influencing block model accuracy and reserve classification. Geometallurgy integrates mineralogical, metallurgical, and geochemical data to predict ore processing characteristics, enabling more precise processing schedules and recovery forecasts. Combining these approaches enhances mine planning by optimizing extraction sequences, processing efficiency, and overall project economics.

Risk Assessment in Estimation and Geometallurgy

Mineral resource estimation involves quantifying the size, grade, and spatial distribution of mineral deposits, which inherently carries uncertainties due to data gaps and geological variability. Geometallurgy integrates geological, metallurgical, and geochemical data to predict ore behavior during processing, reducing operational risks by improving resource utilization and processing efficiency. Risk assessment in estimation addresses volume and grade variability, while geometallurgy mitigates risks related to ore heterogeneity and processing performance, enhancing overall mine planning and economic forecasting.

Technological Tools and Software Comparison

Mineral resource estimation relies heavily on advanced geostatistical software such as Surpac, Datamine, and Leapfrog to model ore bodies and quantify resource grades with spatial accuracy. Geometallurgy integrates data from mineralogy, metallurgy, and geochemistry using tools like SGS Geometallurgical Database, QEMSCAN, and METSIM to optimize processing parameters in relation to ore variability. While resource estimation emphasizes geological modeling and tonnage-grade calculations, geometallurgy focuses on predictive metallurgical performance, leveraging machine learning and process simulation platforms to enhance mine-to-mill strategies.

Trends and Future Synergies in Resource Evaluation

Mineral resource estimation relies heavily on geostatistical models to quantify ore body characteristics, while geometallurgy integrates mineralogical, metallurgical, and geological data to predict processing performance. Emerging trends emphasize the fusion of these disciplines through advanced data analytics and machine learning, enhancing the accuracy of resource valuation and optimization of extraction methods. Future synergies will enable dynamic, real-time resource evaluation, driving sustainable mining practices and improved economic outcomes.

Related Important Terms

Geostatistical Simulation

Mineral resource estimation quantifies ore body tonnage and grade using statistical methods, while geometallurgy integrates geostatistical simulation to model spatial variability in mineral properties, enhancing predictive accuracy for processing performance. Geostatistical simulation captures geological heterogeneity by generating multiple equally probable realizations of mineral distributions, crucial for optimizing extraction and reducing economic risk in mining operations.

Conditional Simulation

Conditional simulation in mineral resource estimation provides probabilistic spatial distributions of ore grades, enabling more accurate risk assessment and resource classification. Geometallurgy integrates conditional simulation outputs with metallurgy data to optimize processing strategies and predict ore variability during mining operations.

Domaining Strategy

Mineral resource estimation relies heavily on accurate domaining strategies to define geological boundaries that influence grade distribution and resource classification, while geometallurgy integrates these domains with metallurgical properties to optimize processing performance. Effective domaining strategies enhance both resource estimation precision and geometallurgical modeling, ensuring improved mine planning and extraction efficiency.

Mineralogical Fingerprinting

Mineralogical fingerprinting in mineral resource estimation provides detailed characterization of ore minerals, enabling precise grade and tonnage predictions by identifying mineral associations and texture variations. Geometallurgy integrates this fingerprinting data to optimize extraction processes, improving metallurgical performance and economic outcomes through targeted mine planning based on mineralogical variability.

Geometallurgical Modelling

Geometallurgical modelling integrates geological, mineralogical, and metallurgical data to predict ore processing behavior and optimize resource extraction strategies, enhancing the accuracy beyond conventional mineral resource estimation. This approach supports detailed block models that incorporate variability in ore characteristics, enabling improved mine planning and economic forecasting.

Resource Classification Uncertainty

Mineral resource estimation relies heavily on geostatistical methods to quantify resource classification uncertainty by analyzing spatial variability and sampling data, while geometallurgy integrates geological, mineralogical, and metallurgical information to reduce uncertainty through better prediction of ore behavior and processing performance. Combining both approaches enhances decision-making accuracy by accounting for variability in resource quality and processing outcomes, ultimately improving mine planning and economic evaluations.

Multi-parameter Block Modelling

Multi-parameter block modelling in mineral resource estimation integrates geological, geotechnical, and metallurgical data to create a comprehensive subsurface representation, enhancing precision in resource quantification and mine planning. Geometallurgy leverages this modelling approach to predict ore variability and optimize processing performance, thereby bridging the gap between geological characteristics and metallurgical behavior.

Geometallurgical Units (GMUs)

Geometallurgical Units (GMUs) integrate geological, mineralogical, and metallurgical data to enhance orebody characterization, enabling more accurate predictions of processing performance and recovery rates. This approach improves resource estimation by linking spatial variability with metal extraction efficiency, optimizing mine planning and operational decisions.

Orebody Knowledge Integration

Mineral resource estimation provides quantitative data on orebody size, grade, and distribution, forming the foundational framework for mining design and economic evaluation. Geometallurgy integrates geological, metallurgical, and spatial data to enhance orebody knowledge, enabling precise prediction of processing behavior and optimization of extraction methods.

Metallurgical Recovery Modifiers

Metallurgical recovery modifiers in mineral resource estimation quantify how ore variability and processing conditions impact metal recovery rates, while geometallurgy integrates detailed geological, mineralogical, and metallurgical data to model spatially variable recoveries more accurately. Incorporating geometallurgical recovery modifiers enables more precise prediction of metal yields, optimizing mine planning and processing strategies.

Mineral resource estimation vs Geometallurgy Infographic

industrydif.com

industrydif.com