Shaft mining involves vertical excavation to access and extract underground mineral resources, offering precise control over ore retrieval but demanding significant infrastructure and safety measures. Bioleaching employs microorganisms to biologically extract metals from ores, reducing environmental impact and operational costs compared to traditional mining methods. While shaft mining provides immediate mineral access, bioleaching presents a sustainable alternative for low-grade ores and complex mineral compositions.

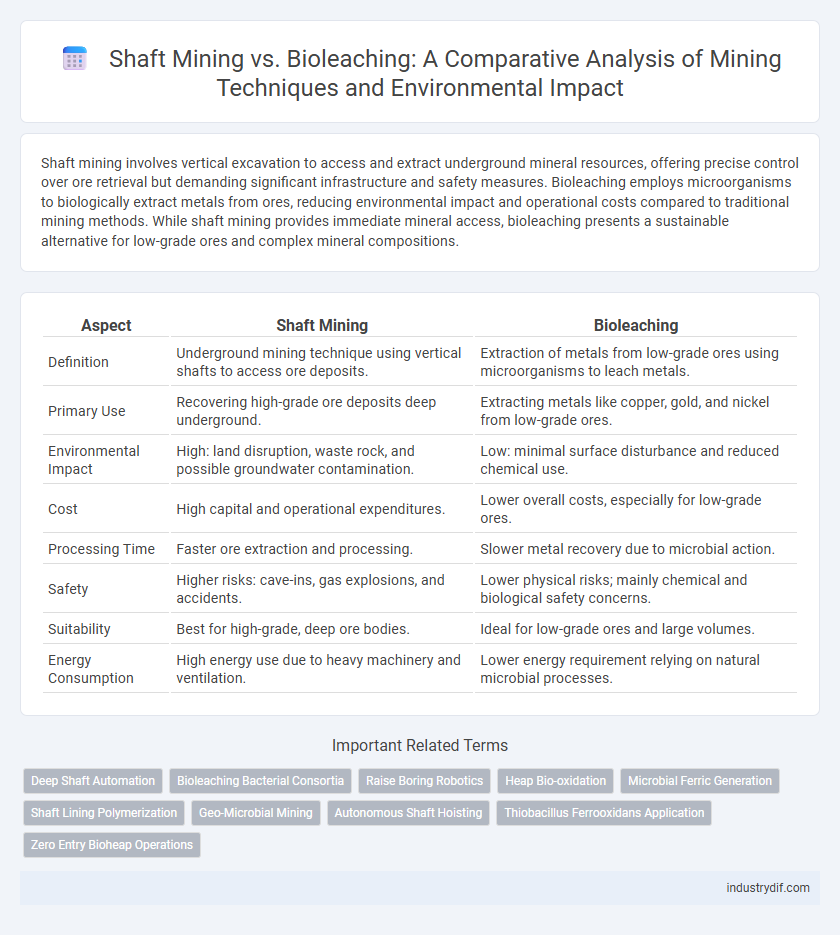

Table of Comparison

| Aspect | Shaft Mining | Bioleaching |

|---|---|---|

| Definition | Underground mining technique using vertical shafts to access ore deposits. | Extraction of metals from low-grade ores using microorganisms to leach metals. |

| Primary Use | Recovering high-grade ore deposits deep underground. | Extracting metals like copper, gold, and nickel from low-grade ores. |

| Environmental Impact | High: land disruption, waste rock, and possible groundwater contamination. | Low: minimal surface disturbance and reduced chemical use. |

| Cost | High capital and operational expenditures. | Lower overall costs, especially for low-grade ores. |

| Processing Time | Faster ore extraction and processing. | Slower metal recovery due to microbial action. |

| Safety | Higher risks: cave-ins, gas explosions, and accidents. | Lower physical risks; mainly chemical and biological safety concerns. |

| Suitability | Best for high-grade, deep ore bodies. | Ideal for low-grade ores and large volumes. |

| Energy Consumption | High energy use due to heavy machinery and ventilation. | Lower energy requirement relying on natural microbial processes. |

Introduction to Shaft Mining and Bioleaching

Shaft mining involves vertical tunnels that reach deep mineral deposits, enabling efficient extraction of ores like gold and copper from underground. Bioleaching uses specialized microorganisms to dissolve metals from ores, offering an eco-friendly alternative for low-grade mineral recovery. Both techniques are vital in modern mining, with shaft mining providing direct access to deposits and bioleaching enhancing sustainable metal extraction.

Definition and Process of Shaft Mining

Shaft mining is an underground mining technique that involves vertical tunnels to access ore deposits deep beneath the surface, typically used for extracting minerals like coal, gold, and diamonds. The process begins with sinking a shaft to reach the ore body, followed by constructing horizontal tunnels or levels for ore removal and ventilation. This method requires extensive engineering to ensure structural stability and safe transport of materials and personnel.

Understanding Bioleaching Techniques

Bioleaching utilizes specialized microorganisms to extract metals like copper, gold, and nickel from low-grade ores, offering an eco-friendly alternative to traditional shaft mining. This technique accelerates metal recovery by oxidizing sulfide minerals, reducing the need for extensive underground excavation and lowering environmental impact. Understanding bioleaching's microbial processes and optimal conditions enhances resource efficiency and supports sustainable mining practices.

Key Differences Between Shaft Mining and Bioleaching

Shaft mining involves the physical excavation of deep vertical tunnels to access mineral deposits, often requiring extensive infrastructure and significant labor costs, whereas bioleaching uses microorganisms to extract metals from ores through biochemical processes, minimizing environmental disruption. Shaft mining provides immediate access to high-grade ores but poses greater safety risks, while bioleaching offers a slower, more sustainable extraction method suitable for low-grade or complex ores. Environmental impact and operational scalability are critical factors distinguishing these mining techniques, with bioleaching presenting lower energy consumption and reduced waste generation compared to the intensive excavation of shaft mining.

Environmental Impact: Shaft Mining vs Bioleaching

Shaft mining typically causes significant environmental disruption, including deforestation, soil erosion, and groundwater contamination due to the extensive excavation and waste rock generation. Bioleaching offers a more sustainable alternative by using microorganisms to extract metals from ores with minimal surface disturbance, reducing toxic waste and lower energy consumption. This environmentally friendly method significantly decreases greenhouse gas emissions and habitat destruction compared to traditional shaft mining techniques.

Economic Efficiency and Cost Analysis

Shaft mining involves substantial upfront capital expenditure for infrastructure development, including excavation, ventilation, and safety systems, resulting in high fixed costs but potentially lower operating costs per ton of ore extracted over time. Bioleaching offers a cost-effective alternative with lower initial investment, utilizing microorganisms to extract metals from low-grade ores, reducing the need for extensive physical excavation and energy consumption. Economic efficiency of bioleaching can be higher for low-grade ores or complex mineral compositions, while shaft mining remains economically viable for high-grade deposits with significant volume.

Safety Considerations in Shaft Mining and Bioleaching

Shaft mining involves significant safety risks such as potential collapses, gas explosions, and exposure to harmful dust, necessitating rigorous monitoring and ventilation systems. Bioleaching offers a safer alternative by minimizing physical hazards through the use of microorganisms to extract metals, reducing the need for workers to be exposed to dangerous underground environments. However, bioleaching requires careful management of chemical and biological processes to prevent environmental contamination and ensure operational safety.

Applications and Suitability for Different Ore Types

Shaft mining is highly suitable for extracting high-grade, deep underground ore bodies such as gold, copper, and zinc, providing direct access to concentrated mineral deposits with minimal dilution. Bioleaching is ideal for low-grade, sulfide-rich ores, including chalcopyrite and pentlandite, leveraging microbial processes to selectively dissolve metals like copper and nickel in a cost-effective and environmentally friendly manner. While shaft mining excels in hard rock conditions requiring extensive infrastructure, bioleaching offers scalable, low-impact solutions for large, low-grade ore bodies where traditional methods are less economical.

Technological Advancements in Both Methods

Technological advancements in shaft mining include automated drilling systems, real-time monitoring sensors, and improved ventilation techniques that enhance safety and efficiency underground. Bioleaching has benefited from breakthroughs in microbial engineering, optimized bioreactor designs, and advanced bioinformatics for selecting high-performance bacteria strains to accelerate metal extraction. Integration of IoT and AI in both methods enables precise resource management, predictive maintenance, and reduced environmental impact.

Future Prospects and Trends in Mining Technologies

Shaft mining continues to evolve with advancements in automation and remote monitoring, improving safety and efficiency in deep mineral extraction. Bioleaching gains traction as an eco-friendly alternative, utilizing microbes to extract metals like copper, gold, and nickel from low-grade ores, reducing environmental impact. Future trends highlight the integration of biotechnology with digital innovations, promising sustainable, cost-effective mineral recovery and deeper resource accessibility.

Related Important Terms

Deep Shaft Automation

Deep shaft automation in mining enhances operational efficiency, safety, and precision by integrating robotics, real-time sensors, and remote control systems in shaft mining, reducing human risk in hazardous underground environments. Bioleaching offers an eco-friendly alternative by utilizing microorganisms to extract metals from ores, but deep shaft automation remains crucial for accessing and managing mineral deposits at greater depths where bioleaching is less effective.

Bioleaching Bacterial Consortia

Bioleaching bacterial consortia, composed of diverse acidophilic microorganisms such as Acidithiobacillus ferrooxidans and Leptospirillum ferrooxidans, offer an eco-friendly alternative to traditional shaft mining by enhancing metal recovery from low-grade ores through biooxidation processes. These microbial communities optimize metal solubilization, reduce environmental impact, and improve overall efficiency compared to conventional mining techniques.

Raise Boring Robotics

Raise boring robotics enhances shaft mining efficiency by automating the excavation of vertical tunnels, reducing human risk and operational downtime. In contrast, bioleaching offers a low-impact alternative for metal extraction using microbes but lacks the precision and speed that raise boring robotics provide in developing mine infrastructure.

Heap Bio-oxidation

Shaft mining involves deep underground excavation to extract ore, offering high recovery rates for valuable minerals but requiring extensive infrastructure and safety measures. Heap bio-oxidation, a form of bioleaching, uses microbial activity to efficiently oxidize sulfide ores on heaps, enhancing metal recovery with lower environmental impact and operational costs compared to traditional shaft mining.

Microbial Ferric Generation

Shaft mining involves extracting ore through vertical tunnels, while bioleaching utilizes microbial ferric generation to oxidize sulfide minerals, enhancing metal solubilization in situ. Microorganisms such as Acidithiobacillus ferrooxidans catalyze ferric ion production, facilitating efficient copper recovery from low-grade ores without extensive excavation.

Shaft Lining Polymerization

Shaft lining polymerization enhances the structural integrity and durability of shaft mining by utilizing advanced polymer materials to reinforce underground shafts against water ingress and mechanical stress. Compared to bioleaching, which relies on microbial processes for mineral extraction, shaft lining polymerization ensures safer and more stable access to ore deposits, crucial for deep mining operations.

Geo-Microbial Mining

Geo-microbial mining leverages bioleaching techniques using microorganisms to extract metals from ores, offering an eco-friendly alternative to conventional shaft mining, which involves extensive underground excavation. This method enhances metal recovery efficiency by harnessing microbial metabolism, reducing environmental impact, and lowering operational costs compared to traditional shaft mining processes.

Autonomous Shaft Hoisting

Autonomous shaft hoisting in shaft mining enhances operational efficiency and safety by using automated systems to transport ore and waste materials, reducing human intervention and downtime. In contrast, bioleaching relies on microbial processes to extract metals from ores in situ, minimizing the need for physical excavation but lacking the immediate extraction speed provided by autonomous shaft hoisting technology.

Thiobacillus Ferrooxidans Application

Thiobacillus ferrooxidans plays a critical role in bioleaching by oxidizing sulfide minerals to extract metals efficiently, offering an environmentally friendly alternative to traditional shaft mining methods that involve extensive excavation and disruption of the earth's crust. The bacterium's ability to facilitate metal recovery from low-grade ores reduces reliance on energy-intensive shaft mining, lowering operational costs and environmental impact in the mining industry.

Zero Entry Bioheap Operations

Zero Entry Bioheap Operations in shaft mining leverage bioleaching techniques to extract metals without human entry into hazardous shafts, significantly reducing safety risks and operational costs. This method enhances ore recovery by utilizing microbial activity to break down minerals within bioheaps, providing an environmentally sustainable alternative to traditional shaft mining practices.

Shaft mining vs Bioleaching Infographic

industrydif.com

industrydif.com