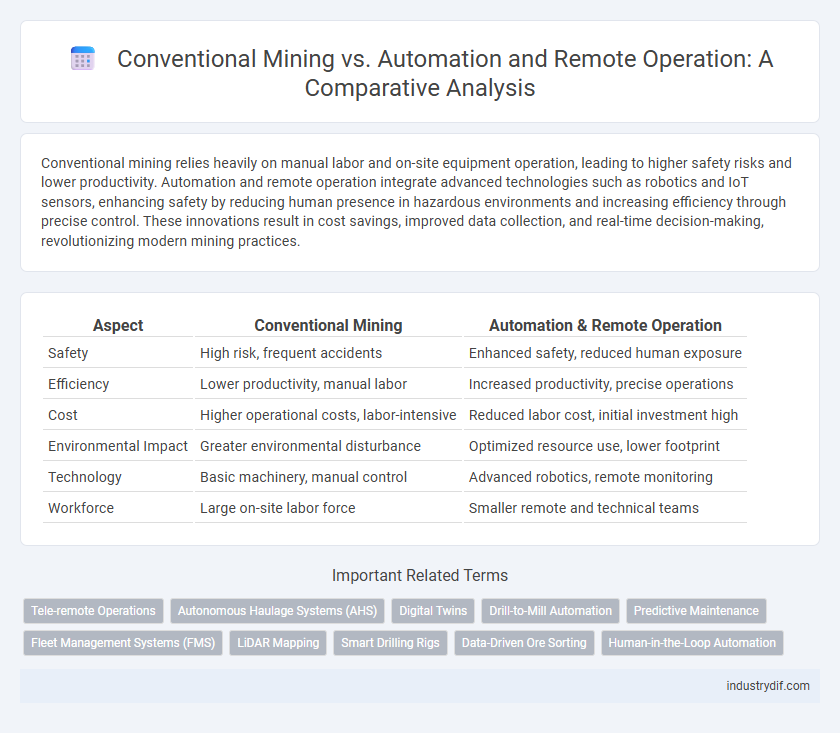

Conventional mining relies heavily on manual labor and on-site equipment operation, leading to higher safety risks and lower productivity. Automation and remote operation integrate advanced technologies such as robotics and IoT sensors, enhancing safety by reducing human presence in hazardous environments and increasing efficiency through precise control. These innovations result in cost savings, improved data collection, and real-time decision-making, revolutionizing modern mining practices.

Table of Comparison

| Aspect | Conventional Mining | Automation & Remote Operation |

|---|---|---|

| Safety | High risk, frequent accidents | Enhanced safety, reduced human exposure |

| Efficiency | Lower productivity, manual labor | Increased productivity, precise operations |

| Cost | Higher operational costs, labor-intensive | Reduced labor cost, initial investment high |

| Environmental Impact | Greater environmental disturbance | Optimized resource use, lower footprint |

| Technology | Basic machinery, manual control | Advanced robotics, remote monitoring |

| Workforce | Large on-site labor force | Smaller remote and technical teams |

Introduction to Conventional Mining Methods

Conventional mining methods involve manual labor-intensive processes such as drilling, blasting, and hauling, typically operated onsite by miners using heavy machinery. These traditional techniques rely heavily on direct human involvement, exposing workers to safety risks and operational inefficiencies. Despite limitations, conventional mining remains prevalent in extracting valuable minerals from underground and surface deposits worldwide.

Evolution of Mining Automation

Conventional mining methods rely heavily on manual labor and on-site equipment operation, leading to higher risks and lower efficiency. Automation and remote operation technologies, including autonomous haul trucks and remote control drilling systems, have revolutionized mining by increasing safety, productivity, and operational precision. The evolution of mining automation integrates IoT sensors, AI-driven analytics, and real-time data management to optimize resource extraction and reduce environmental impact.

Key Technologies in Automated Mining

Automated mining integrates advanced technologies such as autonomous haulage systems (AHS), remote-controlled drilling rigs, and real-time data analytics platforms, significantly improving operational efficiency compared to conventional mining methods. Key technologies include GPS-guided vehicles, IoT sensors for equipment monitoring, and machine learning algorithms for predictive maintenance, enabling continuous operation with reduced human intervention. These innovations enhance safety, optimize resource extraction, and lower operational costs by minimizing downtime and maximizing equipment utilization.

Safety Implications: Manual vs Automated Operations

Conventional mining relies heavily on manual labor, exposing workers to higher risks such as cave-ins, toxic gas exposure, and machinery accidents, which contribute to elevated injury and fatality rates. Automation and remote operation technologies significantly enhance safety by reducing human presence in hazardous environments, utilizing advanced sensors, real-time monitoring, and automated machinery to prevent accidents. These innovations lead to a substantial decline in workplace incidents, promoting safer mining operations and improving overall worker health and safety standards.

Productivity and Efficiency Comparison

Conventional mining methods rely heavily on manual labor and onsite equipment operation, often resulting in slower extraction rates and higher operational costs. Automation and remote operation technologies enhance productivity by enabling continuous mining processes, reducing human error, and minimizing downtime through real-time monitoring and control. These advancements lead to significant efficiency gains, including increased ore recovery rates and lower energy consumption per ton mined.

Environmental Impact: Traditional vs Automated Mining

Conventional mining typically results in higher environmental impact due to extensive land disturbance, increased energy consumption, and greater emissions of greenhouse gases compared to automated and remote mining technologies. Automated mining processes utilize advanced machinery and remote sensing to optimize resource extraction with reduced waste and lower carbon footprints, significantly minimizing water pollution and soil degradation. Remote operations enable precise monitoring and control, leading to enhanced environmental management and decreased disturbance to surrounding ecosystems.

Workforce Skills and Labor Market Changes

Conventional mining relies heavily on manual labor and specialized skilled workers proficient in operating machinery and handling onsite tasks, creating localized labor markets with high demand for physical labor. Automation and remote operation technologies shift workforce requirements toward advanced technical skills, including robotics, data analytics, and systems management, driving a labor market transformation favoring digital literacy and specialized engineering expertise. This evolution reduces hazardous onsite roles but increases demand for remote operators and maintenance technicians, impacting employment patterns and necessitating targeted reskilling programs in mining communities.

Capital and Operational Cost Analysis

Conventional mining requires substantial capital investment in manual labor, equipment, and onsite infrastructure, leading to high operational costs driven by workforce wages, safety measures, and downtime. Automation and remote operation reduce labor expenses and enhance efficiency through real-time monitoring and predictive maintenance, significantly lowering operational costs despite higher initial capital expenditure for advanced technology integration. Long-term cost analysis reveals automation delivers superior return on investment by minimizing disruptions and improving resource utilization compared to traditional mining methods.

Challenges in Implementing Mining Automation

Implementing mining automation faces challenges such as high initial capital investment, the need for advanced workforce training, and integration with existing conventional mining infrastructure. Remote operation demands reliable communication networks and robust cybersecurity measures to ensure uninterrupted and safe mining activities. Additionally, geographical and environmental factors can hinder the deployment and scalability of automated systems in mining sites.

Future Trends in Mining Industry Technologies

Automation and remote operation technologies are revolutionizing the mining industry by increasing safety and operational efficiency while reducing human exposure to hazardous environments. Advanced robotics, AI-driven equipment, and real-time data analytics enable continuous monitoring and decision-making, transforming traditional conventional mining practices. Future trends emphasize integrating IoT devices and autonomous systems to optimize resource extraction and minimize environmental impact.

Related Important Terms

Tele-remote Operations

Tele-remote operations in mining enable operators to control equipment from distant locations, significantly enhancing safety by removing personnel from hazardous environments while improving operational efficiency through real-time data integration. Compared to conventional mining methods that rely heavily on onsite labor and manual control, tele-remote technology reduces downtime, lowers operational costs, and supports continuous, 24/7 mining activities in complex or dangerous conditions.

Autonomous Haulage Systems (AHS)

Conventional mining relies heavily on manual labor and on-site equipment operation, often resulting in higher operational risks and lower efficiency. Autonomous Haulage Systems (AHS) enhance mining productivity by using advanced robotics and AI to perform remote and automated material transport, reducing human error and operational costs while improving safety and real-time data analytics.

Digital Twins

Conventional mining relies on manual labor and physical inspections, whereas automation and remote operation leverage Digital Twins to create precise virtual replicas of mining sites, enabling real-time monitoring and predictive maintenance. Digital Twins enhance operational efficiency, reduce downtime, and improve safety by simulating mining processes and equipment performance in a controlled digital environment.

Drill-to-Mill Automation

Drill-to-mill automation in mining enhances operational efficiency by integrating automated drilling and processing stages, reducing human error and increasing precision compared to conventional mining methods. Remote operation technology enables real-time data monitoring and control, improving safety and productivity by minimizing on-site personnel exposure to hazardous environments.

Predictive Maintenance

Conventional mining relies heavily on scheduled inspections and manual diagnostics, often leading to unexpected equipment failures and costly downtimes. Automation and remote operations utilize predictive maintenance powered by IoT sensors and AI analytics, enabling real-time monitoring and early fault detection to optimize equipment uptime and reduce maintenance costs.

Fleet Management Systems (FMS)

Fleet Management Systems (FMS) in conventional mining rely heavily on manual input and on-site supervision, resulting in limited operational efficiency and increased safety risks. Automation and remote operation leverage advanced FMS technologies with real-time data analytics, GPS tracking, and autonomous vehicle control to optimize fleet utilization, reduce downtime, and enhance worker safety.

LiDAR Mapping

Conventional mining relies heavily on manual surveying methods, which can be time-consuming and prone to human error, whereas automation and remote operation utilize LiDAR mapping to deliver precise, real-time 3D topographical data for enhanced decision-making and operational safety. Integrating LiDAR technology in automated mining systems improves resource estimation accuracy, reduces operational risks, and optimizes excavation processes through continuous, high-resolution terrain analysis.

Smart Drilling Rigs

Conventional mining relies heavily on manual labor and on-site personnel, while automation and remote operation in smart drilling rigs utilize advanced sensors, AI algorithms, and real-time data analytics to enhance precision and safety. Smart drilling rigs integrate automated drilling processes with remote monitoring systems, significantly reducing downtime and operational costs while improving extraction efficiency in mining operations.

Data-Driven Ore Sorting

Conventional mining relies heavily on manual labor and basic sorting techniques, resulting in lower ore recovery rates and higher operational costs. Data-driven ore sorting leverages machine learning algorithms and sensor technologies to enhance precision, reduce waste, and optimize resource extraction through real-time analysis and remote operation capabilities.

Human-in-the-Loop Automation

Human-in-the-Loop automation in mining combines conventional manual oversight with advanced remote operation technologies, enhancing safety and operational efficiency by allowing real-time human intervention during automated tasks. This hybrid approach optimizes resource extraction while reducing downtime and minimizing the risks associated with fully autonomous systems.

Conventional mining vs Automation and remote operation Infographic

industrydif.com

industrydif.com