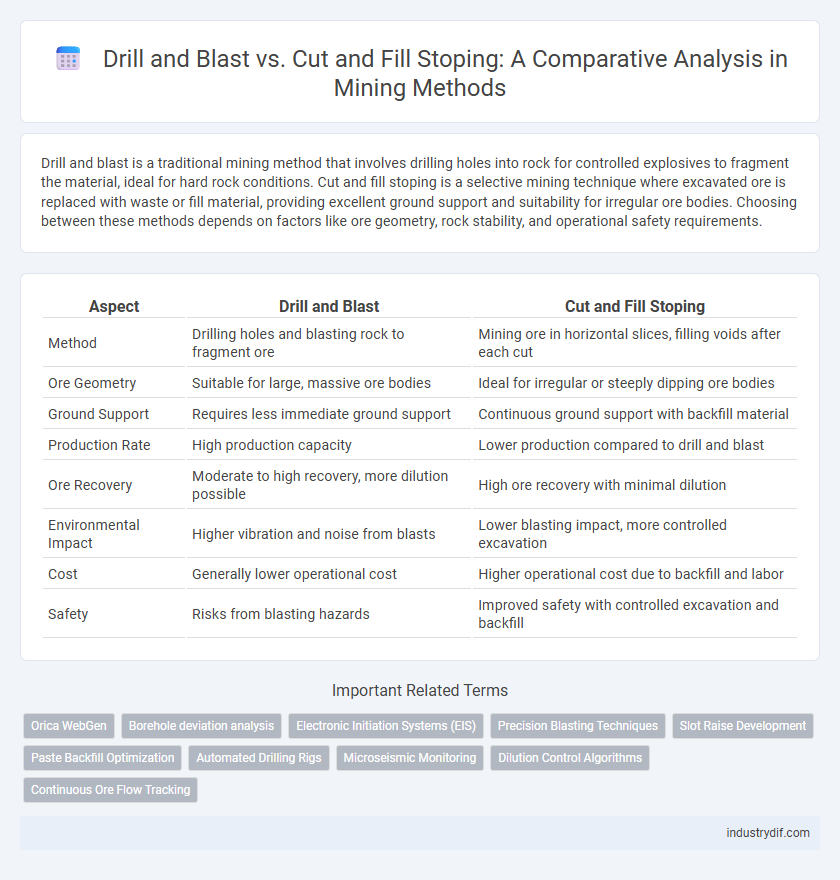

Drill and blast is a traditional mining method that involves drilling holes into rock for controlled explosives to fragment the material, ideal for hard rock conditions. Cut and fill stoping is a selective mining technique where excavated ore is replaced with waste or fill material, providing excellent ground support and suitability for irregular ore bodies. Choosing between these methods depends on factors like ore geometry, rock stability, and operational safety requirements.

Table of Comparison

| Aspect | Drill and Blast | Cut and Fill Stoping |

|---|---|---|

| Method | Drilling holes and blasting rock to fragment ore | Mining ore in horizontal slices, filling voids after each cut |

| Ore Geometry | Suitable for large, massive ore bodies | Ideal for irregular or steeply dipping ore bodies |

| Ground Support | Requires less immediate ground support | Continuous ground support with backfill material |

| Production Rate | High production capacity | Lower production compared to drill and blast |

| Ore Recovery | Moderate to high recovery, more dilution possible | High ore recovery with minimal dilution |

| Environmental Impact | Higher vibration and noise from blasts | Lower blasting impact, more controlled excavation |

| Cost | Generally lower operational cost | Higher operational cost due to backfill and labor |

| Safety | Risks from blasting hazards | Improved safety with controlled excavation and backfill |

Overview of Drill and Blast Mining

Drill and blast mining involves the systematic drilling of holes in rock formations followed by controlled explosive detonations to fragment the material for easier extraction. This method is widely used in both open-pit and underground mining due to its efficiency in breaking hard rock and adaptability to complex ore bodies. Key advantages include cost-effectiveness and high fragmentation control, which enhance productivity and safety in mining operations compared to cut and fill stoping.

Fundamentals of Cut and Fill Stoping

Cut and fill stoping is a mining method ideal for steeply dipping, irregular ore bodies where ground conditions require support during extraction. This technique involves mining ore in horizontal slices, followed by backfilling the void with waste rock or tailings to stabilize the excavation and enable safe access for subsequent slices. Compared to drill and blast, cut and fill stoping offers precise ore control and reduced dilution, enhancing overall recovery and safety in complex underground operations.

Key Differences: Drill and Blast vs Cut and Fill

Drill and blast mining involves drilling holes into rock and detonating explosives to fracture the ore, making it suitable for hard rock and large-scale operations with irregular ore bodies. Cut and fill stoping, on the other hand, is a selective underground mining method where ore is excavated in horizontal slices and backfilled with waste material, providing better ground support and allowing high recovery in steeply dipping, irregular ore zones. Key differences include the scale and selectivity of extraction, ground stability management, and adaptability to ore body geometry, with drill and blast being more efficient for bulk mining and cut and fill preferred for precision and safety in complex underground environments.

Geological Conditions Suited for Each Method

Drill and blast stoping is best suited for hard, massive, and stable rock formations where controlled fragmentation is essential, often used in narrow to medium-width ore bodies with consistent geology. Cut and fill stoping excels in irregular, weak, or highly fractured rock masses, allowing selective ore extraction and ground support, ideal for steeply dipping or variable ore bodies. Geological conditions such as rock strength, ore body shape, and structural stability determine the optimal selection between these two underground mining methods.

Equipment and Technology Utilized

Drill and blast stoping relies on heavy-duty drilling rigs and explosives technology to fragment rock efficiently, optimizing mucking productivity through mechanized loaders and haul trucks. In contrast, cut and fill stoping employs more precise equipment, such as raise drills and fill conveyors, alongside cement or hydraulic fill systems to provide ground support in irregular ore bodies. Advanced automation and remote control technologies enhance safety and operational precision in both methods, yet the equipment selection varies significantly based on ore geometry and ground conditions.

Ore Recovery and Dilution Rates Comparison

Drill and blast method typically achieves ore recovery rates ranging from 70% to 85%, with dilution levels between 15% and 30%, influenced by fragmentation control and blast design. Cut and fill stoping offers higher ore recovery, often exceeding 90%, due to selective mining and backfilling, while maintaining dilution rates below 10%, resulting in improved ore grade retention. The choice between these methods depends on orebody geometry and ground conditions, directly impacting operational efficiency and economic viability.

Safety Considerations in Both Methods

Drill and blast methods pose higher safety risks due to potential fly rock, vibrations, and gas emissions, necessitating strict monitoring and controlled blasting protocols. Cut and fill stoping offers better ground control and reduced exposure to unstable rock by allowing gradual excavation and backfilling, improving worker safety in complex ore bodies. Both methods require comprehensive risk assessments and implementation of ventilation, ground support, and emergency response measures to mitigate operational hazards.

Environmental Impacts and Controls

Drill and blast methods generate significant dust, ground vibrations, and noise pollution, impacting surrounding ecosystems and requiring robust dust suppression and vibration monitoring systems to mitigate environmental harm. Cut and fill stoping produces less airborne particulate matter and ground disturbance, allowing for more controlled waste rock management and reduced habitat disruption through backfilling with tailings or waste material. Effective environmental controls in both methods include continuous air quality monitoring, water runoff management, and the implementation of controlled blasting techniques to minimize ecological footprints in mining operations.

Cost and Productivity Analysis

Drill and blast methods typically offer lower upfront costs and higher productivity in hard rock mining environments due to faster cycle times and greater fragmentation efficiency. Cut and fill stoping, while more expensive owing to extensive ground support and backfilling needs, provides better ore recovery and stability in irregular ore bodies, ultimately reducing dilution costs. Cost analysis favors drill and blast for bulk mining, but productivity and ore grade control make cut and fill preferable in complex geology scenarios.

Choosing the Optimal Method for Your Mine

Drill and blast techniques provide high productivity and flexibility for hard rock mining, allowing for rapid development of large underground stopes. Cut and fill stoping is better suited for irregular ore bodies and weak rock conditions, ensuring ground stability and selective ore extraction with minimal dilution. Selecting the optimal method depends on ore geometry, rock mechanics, production goals, and economic considerations to maximize safety and profitability.

Related Important Terms

Orica WebGen

Orica WebGen enhances drilling precision and explosive placement in drill and blast operations, improving fragmentation and reducing ground vibration compared to traditional cut and fill stoping methods. Its digital initiation technology optimizes blast timing, increases safety, and boosts overall mine productivity by minimizing ore loss and dilution.

Borehole deviation analysis

Borehole deviation analysis in drill and blast mining is critical for ensuring accurate fragmentation and optimal blast outcomes, as deviations can lead to suboptimal rock breakage and increased dilution. In contrast, cut and fill stoping requires precise borehole alignment to maintain stope stability and maximize ore recovery, with deviations potentially compromising fill placement and ground support integrity.

Electronic Initiation Systems (EIS)

Electronic Initiation Systems (EIS) in drill and blast operations provide precise timing control and enhanced safety by reducing misfires and improving blast fragmentation compared to cut and fill stoping, which relies more on mechanical excavation and less on controlled blasting. EIS enables optimized energy use and minimizes ground vibration, making it a superior choice for complex ore bodies requiring efficient rock breakage and stability in underground mining.

Precision Blasting Techniques

Precision blasting techniques in drill and blast operations enhance fragmentation control, reduce ground vibrations, and improve overall safety compared to cut and fill stoping, which relies more on selective excavation and filling to stabilize the ore body. Advanced electronic detonators and directional drilling optimize blast patterns, increasing ore recovery rates and minimizing dilution in complex geological settings.

Slot Raise Development

Slot raise development in mining involves creating a vertical or inclined opening for material extraction and ventilation, where drill and blast is typically preferred for its precision in hard rock conditions and ability to control fragmentation. Cut and fill stoping is often favored for ore zones with irregular shapes or weaker ground, providing better ground support but slower progression compared to the rapid advance achievable with drill and blast methods in slot raise development.

Paste Backfill Optimization

Drill and blast combined with paste backfill optimization significantly improves ore recovery and ground support by efficiently filling voids with cemented tailings, reducing dilution and minimizing surface subsidence. Cut and fill stoping benefits from paste backfill by enabling selective ore extraction in weak ground conditions, enhancing overall mine stability and operational safety.

Automated Drilling Rigs

Automated drilling rigs in drill and blast operations enhance precision and reduce human exposure to hazardous environments, leading to increased efficiency and safety compared to cut and fill stoping. The integration of advanced sensors and real-time data analytics in automated rigs enables optimized fragmentation control and reduced operational downtime in underground mining.

Microseismic Monitoring

Microseismic monitoring provides real-time seismic event detection during drill and blast operations, enabling precise control of rock fragmentation and minimizing ground vibrations. In contrast, cut and fill stoping relies on microseismic data to assess rock mass stability and optimize backfill placement, enhancing safety and structural integrity in underground mining.

Dilution Control Algorithms

Drill and blast stoping employs precise fragmentation modeling and blast optimization algorithms to minimize wall rock dilution and enhance ore recovery, while cut and fill stoping integrates real-time dilution control algorithms that adjust fill placement and extraction sequences to reduce ore loss and contamination. Advanced dilution control algorithms in both methods utilize geostatistical data and sensor feedback to dynamically optimize excavation boundaries and maintain ore quality throughout the mining process.

Continuous Ore Flow Tracking

Drill and blast stoping enables efficient fracturing of ore bodies, facilitating rapid ore removal but often causes uneven ore flow, complicating continuous ore flow tracking. Cut and fill stoping, while slower due to sequential excavation and backfilling, provides more controlled ore extraction that enhances continuous ore flow tracking accuracy and optimizes production scheduling.

Drill and blast vs Cut and fill stoping Infographic

industrydif.com

industrydif.com