Smelting involves high-temperature processing to extract metals from ores through chemical reactions, producing molten metal and slag. Hydrometallurgy uses aqueous solutions to dissolve and recover metals, offering eco-friendly and cost-effective extraction for low-grade ores. Choosing between smelting and hydrometallurgy depends on ore type, environmental impact, and operational costs.

Table of Comparison

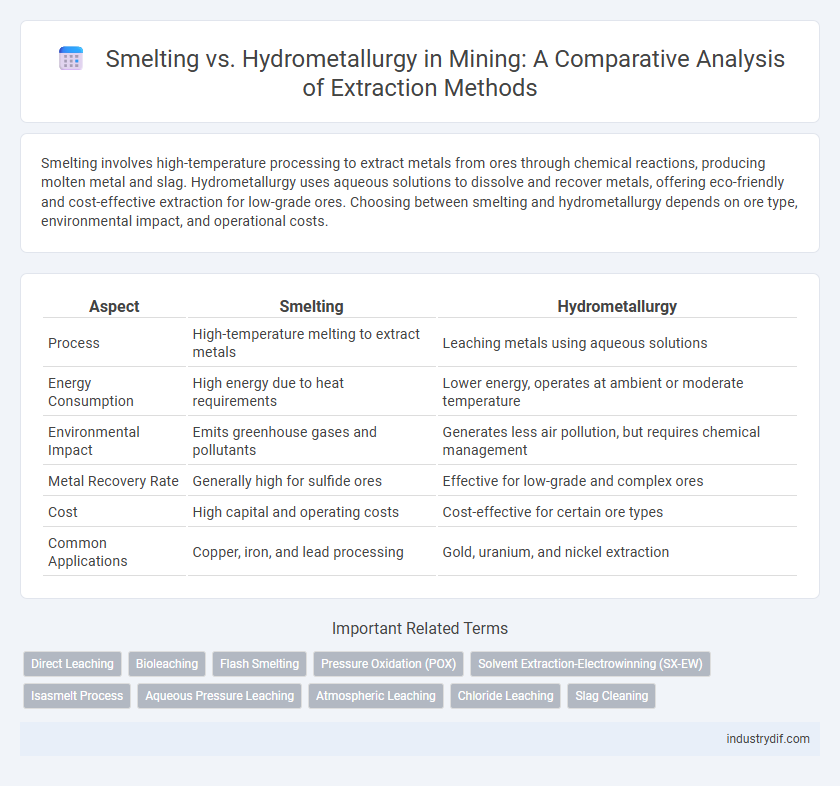

| Aspect | Smelting | Hydrometallurgy |

|---|---|---|

| Process | High-temperature melting to extract metals | Leaching metals using aqueous solutions |

| Energy Consumption | High energy due to heat requirements | Lower energy, operates at ambient or moderate temperature |

| Environmental Impact | Emits greenhouse gases and pollutants | Generates less air pollution, but requires chemical management |

| Metal Recovery Rate | Generally high for sulfide ores | Effective for low-grade and complex ores |

| Cost | High capital and operating costs | Cost-effective for certain ore types |

| Common Applications | Copper, iron, and lead processing | Gold, uranium, and nickel extraction |

Introduction to Mineral Processing Techniques

Smelting and hydrometallurgy are fundamental mineral processing techniques used to extract metals from ores, with smelting relying on high-temperature chemical reduction and hydrometallurgy employing aqueous solutions for metal recovery. Smelting is generally effective for sulfide ores like copper and lead, involving roasting and melting to separate metals from impurities, while hydrometallurgy suits low-grade and complex ores through leaching, solvent extraction, and electrowinning. Advances in hydrometallurgical methods offer environmentally friendly alternatives with lower energy consumption compared to traditional smelting processes.

Defining Smelting in the Mining Industry

Smelting in the mining industry refers to the high-temperature process that extracts valuable metals from their ores by melting and chemical reduction, typically involving furnaces such as blast or electric arc furnaces. This pyrometallurgical technique separates impurities from metal, producing a purified molten metal and slag byproduct. Unlike hydrometallurgy, which uses aqueous chemistry for metal recovery, smelting relies on thermal energy to achieve metallurgical transformation and metal extraction.

Fundamentals of Hydrometallurgy

Hydrometallurgy involves extracting metals from ores through aqueous chemistry, primarily using leaching solutions to dissolve desired metals. This process efficiently recovers metals like copper, gold, and nickel at lower temperatures compared to smelting, reducing energy consumption and environmental emissions. Key hydrometallurgical techniques include solvent extraction, precipitation, and electrowinning, which optimize metal recovery and purity.

Key Differences Between Smelting and Hydrometallurgy

Smelting involves high-temperature processing to extract metals from ores, producing molten metal and slag, whereas hydrometallurgy relies on aqueous chemistry to leach metals at lower temperatures. Smelting is energy-intensive and generates significant air pollutants, while hydrometallurgy offers a more environmentally friendly, solvent-based extraction with reduced emissions. The choice between smelting and hydrometallurgy depends on ore type, metal recovery efficiency, and environmental regulations impacting mining operations.

Common Applications of Smelting

Smelting is widely used in the extraction of metals such as iron, copper, lead, and nickel from their ores through high-temperature processes that separate metal from impurities. Common applications of smelting include the production of pig iron in blast furnaces, copper refining through converting and reverberatory furnaces, and lead recovery via sintering and molten reduction. This method is favored for its efficiency in handling sulfide and oxide ores in large-scale metallurgical operations.

Hydrometallurgical Processes in Modern Mining

Hydrometallurgical processes in modern mining involve the use of aqueous chemistry to extract metals from ores, providing an energy-efficient and environmentally friendly alternative to traditional smelting. Techniques such as leaching, solvent extraction, and electrowinning enable the recovery of valuable metals like copper, gold, and nickel from low-grade ores and complex materials. The increasing adoption of hydrometallurgy supports sustainable mining practices by minimizing greenhouse gas emissions and reducing the production of hazardous byproducts.

Environmental Impact: Smelting vs Hydrometallurgy

Smelting generates significant air pollution through the release of sulfur dioxide and heavy metals, contributing to acid rain and respiratory issues, while also producing slag waste that poses disposal challenges. Hydrometallurgy typically has a lower environmental footprint by utilizing aqueous solutions that reduce air emissions and energy consumption, though it may generate hazardous liquid effluents requiring careful management. The choice between smelting and hydrometallurgy hinges on balancing emissions control, waste treatment efficiency, and the potential for soil and water contamination.

Economic Considerations in Process Selection

Smelting demands significant capital investment and higher energy costs but offers faster throughput and established scalability for large ore volumes. Hydrometallurgy presents lower upfront expenses and improved metal recovery rates from low-grade ores, reducing operational costs over time. Economic considerations favor hydrometallurgy when processing complex or low-grade ores, while smelting remains cost-effective for high-grade, bulk mining operations.

Technological Advancements in Extraction Methods

Technological advancements in smelting have led to the development of flash smelting and continuous casting, significantly increasing energy efficiency and reducing emissions in metal extraction. Hydrometallurgy innovations, such as bioleaching and solvent extraction, enable low-grade ore processing with minimal environmental impact. Both methods benefit from automation and real-time monitoring systems, enhancing precision and scalability in mineral recovery.

Future Trends in Metal Extraction Methods

Future trends in metal extraction emphasize the shift towards hydrometallurgy due to its lower energy consumption and reduced environmental impact compared to traditional smelting. Advances in leaching technologies and solvent extraction improve the recovery rates of metals such as copper, nickel, and cobalt from low-grade ores and complex concentrates. Integration of digital monitoring and automation in hydrometallurgical processes enhances efficiency and sustainability in the mining industry's evolving landscape.

Related Important Terms

Direct Leaching

Direct leaching in hydrometallurgy offers a more energy-efficient and environmentally friendly alternative to traditional smelting by extracting metals directly from ores using chemical solutions. This method reduces greenhouse gas emissions and lowers operational costs while enabling the recovery of metals with minimal residue compared to high-temperature smelting processes.

Bioleaching

Bioleaching, a hydrometallurgical process, uses bacteria to extract metals such as copper, gold, and nickel from ores, offering an environmentally friendly and cost-effective alternative to traditional smelting, which involves high-temperature melting to separate metals. This method reduces energy consumption and greenhouse gas emissions, making bioleaching advantageous for low-grade and complex ores where smelting is less efficient or economically viable.

Flash Smelting

Flash smelting offers a highly energy-efficient method for extracting metals by rapidly oxidizing sulfide ores at high temperatures, significantly reducing greenhouse gas emissions compared to traditional smelting techniques. Hydrometallurgy, while effective for low-grade ores through aqueous chemical processes, typically involves longer processing times and higher reagent consumption, making flash smelting more favorable for large-scale sulfur-rich concentrates.

Pressure Oxidation (POX)

Pressure Oxidation (POX) in hydrometallurgy uses high-pressure oxygen and temperature to break down refractory sulfide ores, enabling efficient metal extraction compared to traditional smelting. POX offers environmental benefits by reducing sulfur dioxide emissions and energy consumption while improving recovery rates for metals like gold and copper.

Solvent Extraction-Electrowinning (SX-EW)

Smelting involves high-temperature processing to extract metals from ores, whereas Hydrometallurgy, particularly Solvent Extraction-Electrowinning (SX-EW), uses aqueous solutions to selectively separate and recover metals such as copper with lower energy consumption and reduced environmental impact. SX-EW enables precise metal purification through solvent extraction followed by electrowinning, making it a cost-effective and sustainable alternative to traditional smelting for copper and other base metals.

Isasmelt Process

The Isasmelt process combines high-intensity smelting with continuous feed of ores and concentrates, offering superior energy efficiency and reduced emissions compared to traditional smelting methods. Hydrometallurgy, while effective for low-grade ores through leaching and solvent extraction, often requires longer processing times and generates larger volumes of wastewater.

Aqueous Pressure Leaching

Aqueous pressure leaching offers enhanced metal recovery by using high-pressure, high-temperature aqueous solutions to dissolve ores, outperforming traditional smelting methods that rely on high-temperature melting and chemical reduction. This hydrometallurgical technique improves environmental outcomes by reducing emissions and energy consumption compared to the energy-intensive smelting process.

Atmospheric Leaching

Atmospheric leaching is a hydrometallurgical process that uses chemical solutions under ambient pressure to extract valuable metals from ores, offering lower energy consumption and reduced environmental impact compared to traditional smelting methods. This technique is particularly effective for complex sulfide ores, enabling the recovery of metals such as copper, nickel, and cobalt with higher selectivity and less greenhouse gas emissions.

Chloride Leaching

Chloride leaching, a hydrometallurgical process, offers higher selectivity and lower environmental impact compared to traditional smelting, enabling efficient extraction of metals such as copper and gold. This method reduces energy consumption and toxic emissions by operating at lower temperatures while enhancing metal recovery rates through controlled chemical reactions.

Slag Cleaning

Slag cleaning in smelting involves the removal of impurities from molten metal through flux addition and controlled cooling, enhancing metal purity but generating substantial solid waste. Hydrometallurgy achieves slag cleaning by dissolving metal oxides in acidic or basic solutions, allowing selective metal recovery with reduced solid residues and lower environmental impact.

Smelting vs Hydrometallurgy Infographic

industrydif.com

industrydif.com