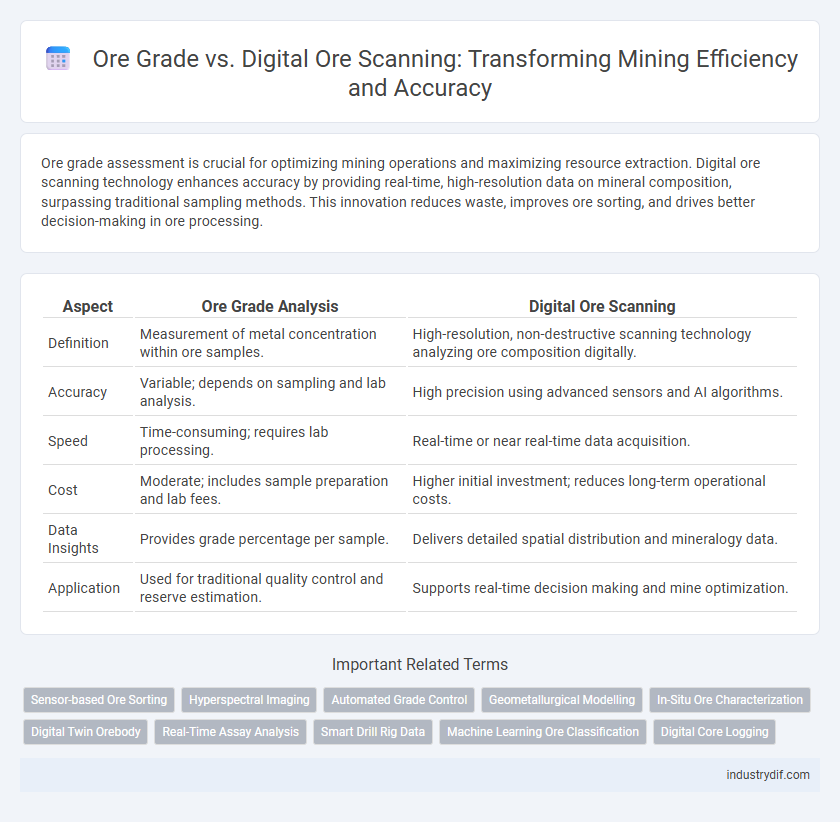

Ore grade assessment is crucial for optimizing mining operations and maximizing resource extraction. Digital ore scanning technology enhances accuracy by providing real-time, high-resolution data on mineral composition, surpassing traditional sampling methods. This innovation reduces waste, improves ore sorting, and drives better decision-making in ore processing.

Table of Comparison

| Aspect | Ore Grade Analysis | Digital Ore Scanning |

|---|---|---|

| Definition | Measurement of metal concentration within ore samples. | High-resolution, non-destructive scanning technology analyzing ore composition digitally. |

| Accuracy | Variable; depends on sampling and lab analysis. | High precision using advanced sensors and AI algorithms. |

| Speed | Time-consuming; requires lab processing. | Real-time or near real-time data acquisition. |

| Cost | Moderate; includes sample preparation and lab fees. | Higher initial investment; reduces long-term operational costs. |

| Data Insights | Provides grade percentage per sample. | Delivers detailed spatial distribution and mineralogy data. |

| Application | Used for traditional quality control and reserve estimation. | Supports real-time decision making and mine optimization. |

Understanding Ore Grade: Key Metrics and Importance

Ore grade, measured as the concentration of valuable minerals within extracted material, is a critical metric directly influencing mining profitability and operational efficiency. Digital ore scanning technologies enable precise, real-time analysis of ore grade variability, enhancing resource estimation and reducing dilution during extraction. Understanding ore grade distribution through digital scanning optimizes mine planning and ensures optimal recoveries while minimizing environmental impact.

Evolution of Ore Grade Assessment in Mining

Digital ore scanning has revolutionized ore grade assessment by providing real-time, high-resolution mineralogical data that surpasses traditional assay methods. Advances in hyperspectral imaging and X-ray fluorescence allow precise identification and quantification of ore components, minimizing sampling errors and enhancing grade control accuracy. This evolution enables more efficient resource estimation, optimized extraction processes, and reduced operational costs in mining projects.

Challenges of Traditional Ore Grade Measurement

Traditional ore grade measurement relies heavily on manual sampling, which often results in inconsistent data due to sampling bias and heterogeneous ore distribution. The time-consuming nature of laboratory assays causes delays in decision-making and limits real-time mine optimization. Digital ore scanning addresses these challenges by providing rapid, high-resolution compositional data that enhances accuracy and supports dynamic resource modeling.

Introduction to Digital Ore Scanning Technologies

Digital Ore Scanning technologies revolutionize ore grade assessment by providing precise mineralogical data through automated imaging and sensor-based analysis. These systems utilize hyperspectral imaging, X-ray fluorescence, and laser scanning to rapidly determine ore composition and grade variability with higher accuracy than traditional sampling methods. Enhanced ore characterization improves resource estimation, optimizes mill feed, and reduces operational costs in mining extraction processes.

Digital Ore Scanning vs. Conventional Assay Methods

Digital ore scanning offers precise mineralogical data and real-time analysis, surpassing conventional assay methods that often require longer processing times and sample destruction. This technology enables accurate ore grade estimation by detecting mineral phases and textures, improving resource modeling and reducing sampling errors. Compared to traditional assays, digital ore scanning optimizes mining efficiency and enhances decision-making in ore valuation.

Impact of Digital Scanning on Ore Grade Analysis Accuracy

Digital ore scanning technology significantly enhances ore grade analysis accuracy by providing high-resolution, real-time compositional data that traditional sampling methods often miss. Advanced sensors and imaging techniques enable precise mineral identification and quantification, reducing sampling errors and improving geological modeling. This improved accuracy directly supports optimized extraction strategies, higher metal recovery rates, and reduced operational costs in mining operations.

Real-Time Data Collection for Ore Grade Optimization

Real-time digital ore scanning enhances ore grade optimization by providing immediate and precise data on mineral composition during extraction, enabling dynamic adjustments to processing parameters. This technology reduces reliance on traditional, time-consuming assay results, increasing operational efficiency and minimizing dilution and ore loss. Integration of sensors and machine learning algorithms ensures continuous monitoring, leading to improved resource estimation and better decision-making in the mining workflow.

Cost Efficiency: Digital Scanning vs. Manual Sampling

Digital ore scanning offers significant cost efficiency compared to manual sampling by reducing labor-intensive processes and enabling faster data acquisition with higher accuracy. Automated ore grade analysis minimizes errors and sample handling costs, optimizing resource allocation and reducing downtime in mining operations. The integration of advanced sensors and AI-driven analytics further enhances decision-making efficiency, leading to substantial savings in operational expenses.

Enhancing Resource Recovery with Digital Ore Scanning

Digital ore scanning significantly enhances resource recovery by providing precise, real-time data on ore grade variability across the deposit, enabling more accurate selective mining and processing. High-resolution imaging and sensor technologies allow mining operations to identify mineral concentrations with greater accuracy compared to traditional sampling methods. This precision reduces dilution and waste, optimizing ore extraction efficiency and increasing overall economic returns.

Future Trends: Integrating AI with Ore Grade Analytics

Future trends in mining emphasize integrating AI with ore grade analytics to enhance accuracy and efficiency in resource estimation. Digital ore scanning technology combined with machine learning algorithms enables real-time analysis of mineral composition, reducing exploration risks and operational costs. Advanced AI models facilitate predictive analytics, optimizing ore grade classification and improving decision-making processes across mining value chains.

Related Important Terms

Sensor-based Ore Sorting

Sensor-based ore sorting technologies enable real-time digital ore scanning, significantly enhancing ore grade assessment accuracy by detecting mineralogical variations at a granular level. This method optimizes resource utilization and reduces processing costs by pre-concentrating high-grade material, improving overall mine yield and sustainability.

Hyperspectral Imaging

Hyperspectral imaging enhances ore grade estimation by providing precise mineralogical data through digital ore scanning, enabling accurate identification of ore composition and quality variations at a micron-scale. This technology significantly improves the efficiency and accuracy of mining operations by reducing reliance on traditional sampling methods and enabling real-time, high-resolution analysis of ore grade distribution.

Automated Grade Control

Automated Grade Control (AGC) leverages digital ore scanning to provide real-time, high-resolution data on ore grade distribution, enhancing precision in ore processing decisions. This integration minimizes grade variability, maximizes resource recovery, and optimizes operational efficiency in mining workflows.

Geometallurgical Modelling

Geometallurgical modelling integrates ore grade data and digital ore scanning technologies to enhance the accuracy of mineral characterization and resource estimation. This approach improves predictive capabilities for ore variability, optimizing extraction processes and maximizing resource efficiency.

In-Situ Ore Characterization

In-situ ore characterization using digital ore scanning provides precise mineralogical and compositional data, enabling accurate assessment of ore grade variability within the deposit. This technology enhances grade control by reducing sampling errors and accelerating decision-making compared to traditional assay methods.

Digital Twin Orebody

Digital ore scanning enhances ore grade estimation accuracy by creating a detailed Digital Twin Orebody, enabling real-time data integration and spatial analysis for improved resource modeling. This technology reduces sampling bias and optimizes mining plans by providing comprehensive, high-resolution insights into ore variability and mineral distribution.

Real-Time Assay Analysis

Real-time assay analysis through digital ore scanning provides precise measurement of ore grade, enabling immediate optimization of extraction processes and reducing sampling errors. Advanced sensor technologies combined with machine learning algorithms enhance the accuracy and speed of ore grade assessment, improving resource estimation and operational efficiency in mining.

Smart Drill Rig Data

Smart Drill Rig Data enhances ore grade estimation by providing precise, real-time digital ore scanning information that significantly improves resource modeling accuracy. Integrating high-resolution sensor data with ore grade analytics allows for optimized excavation strategies and reduced sampling uncertainties.

Machine Learning Ore Classification

Machine learning ore classification enhances digital ore scanning by accurately predicting ore grades through advanced pattern recognition in mineral compositions. This technology improves ore grade estimation, reduces sampling errors, and optimizes mining resource allocation for higher extraction efficiency.

Digital Core Logging

Digital core logging enhances ore grade estimation by providing high-resolution, real-time data that improves mineral identification and reduces sampling errors. This technology integrates advanced imaging and analytical tools to deliver precise geological models, optimizing resource evaluation and mining efficiency.

Ore grade vs Digital ore scanning Infographic

industrydif.com

industrydif.com