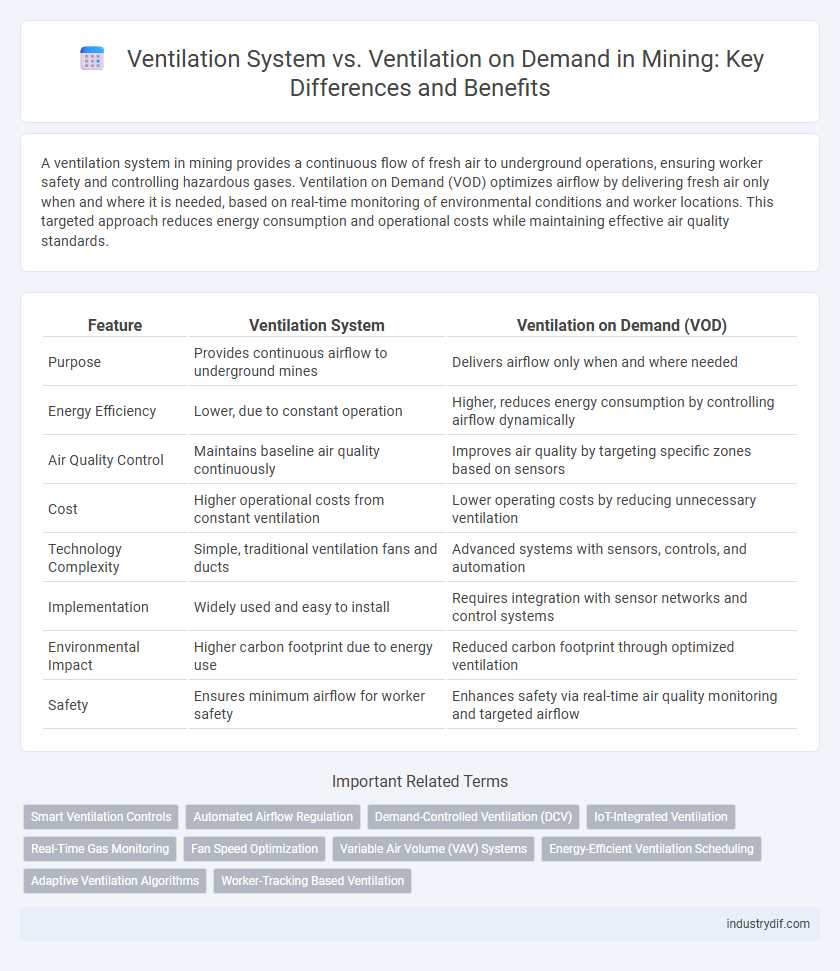

A ventilation system in mining provides a continuous flow of fresh air to underground operations, ensuring worker safety and controlling hazardous gases. Ventilation on Demand (VOD) optimizes airflow by delivering fresh air only when and where it is needed, based on real-time monitoring of environmental conditions and worker locations. This targeted approach reduces energy consumption and operational costs while maintaining effective air quality standards.

Table of Comparison

| Feature | Ventilation System | Ventilation on Demand (VOD) |

|---|---|---|

| Purpose | Provides continuous airflow to underground mines | Delivers airflow only when and where needed |

| Energy Efficiency | Lower, due to constant operation | Higher, reduces energy consumption by controlling airflow dynamically |

| Air Quality Control | Maintains baseline air quality continuously | Improves air quality by targeting specific zones based on sensors |

| Cost | Higher operational costs from constant ventilation | Lower operating costs by reducing unnecessary ventilation |

| Technology Complexity | Simple, traditional ventilation fans and ducts | Advanced systems with sensors, controls, and automation |

| Implementation | Widely used and easy to install | Requires integration with sensor networks and control systems |

| Environmental Impact | Higher carbon footprint due to energy use | Reduced carbon footprint through optimized ventilation |

| Safety | Ensures minimum airflow for worker safety | Enhances safety via real-time air quality monitoring and targeted airflow |

Introduction to Mine Ventilation Systems

Mine ventilation systems are essential for maintaining air quality and ensuring the safety of underground mining operations by controlling airflow, temperature, and hazardous gas levels. Traditional ventilation systems provide continuous airflow throughout the mine, while Ventilation on Demand (VoD) technology optimizes air distribution by adjusting ventilation based on real-time monitoring of mine conditions and personnel location. Implementing VoD reduces energy consumption and operational costs while enhancing mine safety through targeted airflow management.

Fundamentals of Traditional Ventilation Systems

Traditional ventilation systems in mining rely on continuous airflow generated by large fans to dilute and remove harmful gases, dust, and heat from underground workings. These systems operate on fixed airflow rates regardless of real-time environmental conditions, leading to potential energy inefficiencies. The fundamental design involves a network of intake and exhaust shafts, regulators, and ducts to maintain breathable air quality throughout the mine.

Understanding Ventilation on Demand (VoD)

Ventilation on Demand (VoD) in mining optimizes airflow by adjusting ventilation based on real-time monitoring of gas levels, worker locations, and equipment activity, significantly reducing energy consumption compared to traditional fixed ventilation systems. VoD integrates sensors and automated controls to deliver targeted airflow only where and when it is needed, enhancing both safety and operational efficiency underground. This system supports compliance with health and safety regulations by continuously managing air quality and reducing hazardous gas accumulation in mine environments.

Key Differences Between Conventional Ventilation and VoD

Conventional ventilation systems in mining rely on constant airflow, maintaining fixed rates regardless of real-time conditions, which often results in energy inefficiency. Ventilation on Demand (VoD) optimizes airflow by adjusting ventilation based on sensor data such as gas levels, temperature, and worker location, significantly reducing energy consumption. Key differences include the adaptive nature of VoD providing targeted air supply, improved safety through continuous monitoring, and substantial cost savings compared to traditional constant ventilation methods.

Energy Efficiency: Standard vs On-Demand Approaches

Standard ventilation systems in mining operate continuously, leading to higher energy consumption and increased operational costs due to constant fan usage. Ventilation on Demand (VoD) technology optimizes airflow by adjusting fan speeds and air distribution based on real-time sensor data, significantly reducing energy usage and improving overall mine safety. Implementing VoD can result in energy savings of up to 40% compared to traditional ventilation methods by supplying air only where and when it is needed.

Safety and Compliance in Ventilation Systems

Ventilation systems in mining ensure compliance with safety regulations by maintaining adequate airflow to control hazardous gases and dust levels, reducing risks of explosions and respiratory issues. Ventilation on Demand (VoD) technology enhances safety by dynamically adjusting airflow based on real-time monitoring of worker locations and contaminant concentrations, ensuring efficient air distribution only where needed. This targeted approach not only meets regulatory standards but also optimizes energy use while maintaining a safe underground environment.

Technological Components of Ventilation on Demand

Ventilation on Demand (VoD) systems incorporate advanced technological components such as real-time gas sensors, variable speed fans, and intelligent control units that optimize airflow based on underground air quality and worker location. These components reduce energy consumption by adjusting ventilation dynamically, in contrast to traditional ventilation systems that operate continuously at fixed rates. Integration of IoT devices and wireless communication enhances data collection and system responsiveness, improving safety and operational efficiency in mining environments.

Operational Flexibility and Control in Ventilation

Ventilation systems in mining traditionally provide continuous airflow, but Ventilation on Demand (VoD) technology enhances operational flexibility by adjusting airflow based on real-time environmental data and personnel location. This dynamic control reduces energy consumption while maintaining safety standards, optimizing both air quality and operational efficiency. Implementing VoD enables mines to respond swiftly to changing conditions, improving overall ventilation management and reducing operational costs.

Cost Implications: Initial Investment and Long-Term Savings

Ventilation systems in mining require substantial initial investment, with traditional systems often demanding higher upfront costs due to fixed infrastructure and continuous operation. Ventilation on Demand (VoD) technology, however, optimizes airflow by adjusting ventilation based on real-time conditions, reducing energy consumption and leading to significant long-term savings on operational expenses. Implementing VoD reduces power costs by up to 40%, lowers maintenance expenses, and improves overall mine safety, enhancing cost efficiency over the mine's lifecycle.

Future Trends in Mining Ventilation Technologies

Future trends in mining ventilation technologies emphasize the shift from traditional ventilation systems to Ventilation on Demand (VoD) solutions driven by real-time data and automation. VoD enhances energy efficiency by dynamically adjusting airflow based on miner location and equipment emissions, reducing operational costs and environmental impact. Integration of IoT sensors and AI analytics is transforming mine safety and environmental control, fostering more sustainable and responsive ventilation strategies.

Related Important Terms

Smart Ventilation Controls

Smart ventilation controls in mining optimize airflow by dynamically adjusting the ventilation system based on real-time data from sensors, reducing energy consumption and improving air quality. Ventilation on Demand (VoD) enhances traditional ventilation systems by targeting specific zones, ensuring efficient delivery of fresh air only where miners are present.

Automated Airflow Regulation

Automated airflow regulation in Ventilation on Demand (VoD) systems outperforms traditional Ventilation Systems by dynamically adjusting airflow based on real-time sensor data, optimizing energy consumption and improving air quality in underground mines. This advanced control reduces operational costs and enhances worker safety by precisely targeting ventilation where and when it is needed.

Demand-Controlled Ventilation (DCV)

Demand-Controlled Ventilation (DCV) in mining optimizes airflow by adjusting ventilation rates based on real-time sensor data such as gas concentrations, temperature, and occupancy levels, enhancing energy efficiency and worker safety. Traditional ventilation systems operate continuously at fixed rates, leading to unnecessary energy consumption, whereas DCV dynamically responds to mine conditions, reducing operational costs and minimizing environmental impact.

IoT-Integrated Ventilation

IoT-integrated ventilation systems in mining enhance operational efficiency by enabling real-time monitoring and adaptive airflow control, reducing energy consumption compared to traditional ventilation systems. Ventilation on Demand leverages sensors and IoT technology to optimize air quality and miner safety, dynamically adjusting ventilation based on underground activity and contaminant levels.

Real-Time Gas Monitoring

Real-time gas monitoring in ventilation systems enhances miner safety by continuously detecting hazardous gas levels and automatically adjusting airflow to maintain optimal air quality. Ventilation on Demand (VoD) leverages this data-driven approach to optimize energy efficiency and reduce ventilation costs while ensuring compliant and adaptive underground air circulation.

Fan Speed Optimization

Ventilation System with Fan Speed Optimization adjusts airflow based on fixed schedules or sensor input to maintain consistent air quality, reducing energy consumption compared to traditional static systems. Ventilation on Demand dynamically modulates fan speeds in real-time using advanced sensors to respond directly to changes in mine air quality and occupancy, maximizing energy efficiency and improving miner safety.

Variable Air Volume (VAV) Systems

Variable Air Volume (VAV) systems in mining ventilation optimize airflow by adjusting volume based on real-time demand, reducing energy consumption compared to traditional constant airflow ventilation systems. Ventilation on Demand enhances safety and operational efficiency by delivering precise airflow control, minimizing unnecessary ventilation in low-activity areas while maintaining air quality and contaminant control.

Energy-Efficient Ventilation Scheduling

Energy-efficient ventilation scheduling in mining prioritizes Ventilation on Demand (VoD) by dynamically adjusting airflow based on real-time sensor data to reduce energy consumption compared to traditional fixed Ventilation Systems. VoD optimizes fan speed and airflow distribution, leading to substantial energy savings and improved mine air quality while maintaining regulatory compliance.

Adaptive Ventilation Algorithms

Adaptive ventilation algorithms in mining optimize airflow by dynamically adjusting ventilation systems based on real-time gas levels and worker locations, significantly reducing energy consumption and improving safety. Ventilation on Demand leverages these algorithms to provide precise, need-based airflow control compared to traditional constant ventilation systems, enhancing operational efficiency and environmental compliance.

Worker-Tracking Based Ventilation

Worker-tracking based ventilation optimizes air flow by dynamically adjusting ventilation systems according to real-time miner locations, enhancing energy efficiency and reducing operational costs compared to traditional fixed ventilation systems. This technology integrates IoT sensors and automated controls to maintain optimal air quality and ensure miner safety in complex underground mining environments.

Ventilation System vs Ventilation on Demand Infographic

industrydif.com

industrydif.com