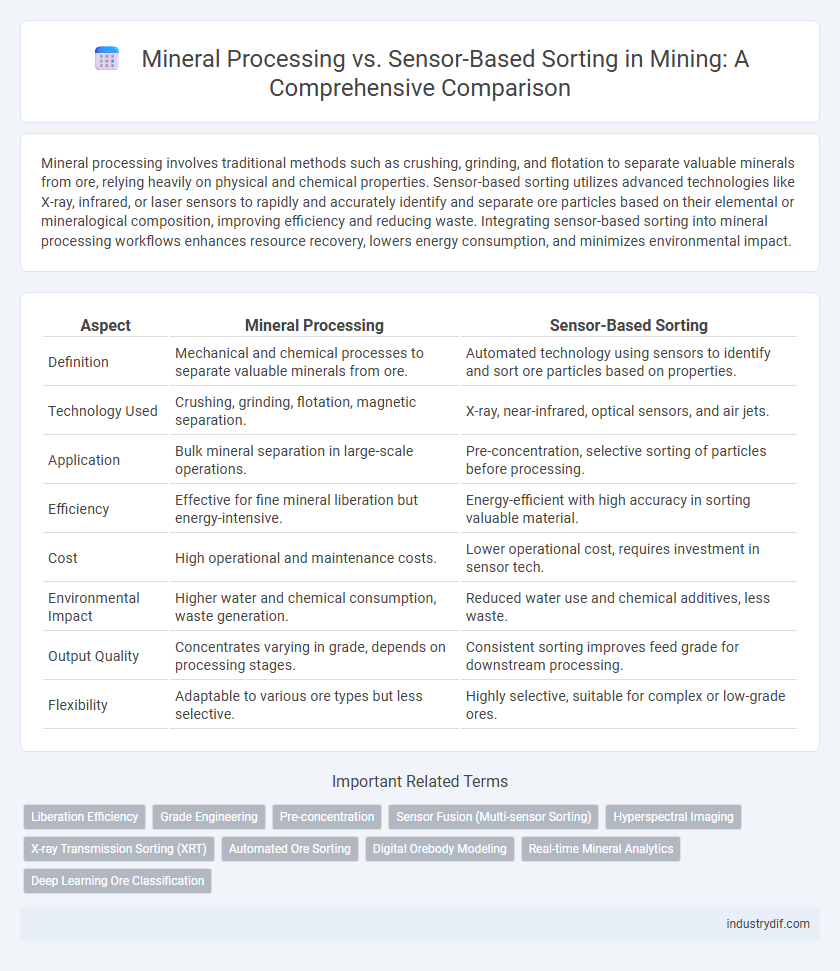

Mineral processing involves traditional methods such as crushing, grinding, and flotation to separate valuable minerals from ore, relying heavily on physical and chemical properties. Sensor-based sorting utilizes advanced technologies like X-ray, infrared, or laser sensors to rapidly and accurately identify and separate ore particles based on their elemental or mineralogical composition, improving efficiency and reducing waste. Integrating sensor-based sorting into mineral processing workflows enhances resource recovery, lowers energy consumption, and minimizes environmental impact.

Table of Comparison

| Aspect | Mineral Processing | Sensor-Based Sorting |

|---|---|---|

| Definition | Mechanical and chemical processes to separate valuable minerals from ore. | Automated technology using sensors to identify and sort ore particles based on properties. |

| Technology Used | Crushing, grinding, flotation, magnetic separation. | X-ray, near-infrared, optical sensors, and air jets. |

| Application | Bulk mineral separation in large-scale operations. | Pre-concentration, selective sorting of particles before processing. |

| Efficiency | Effective for fine mineral liberation but energy-intensive. | Energy-efficient with high accuracy in sorting valuable material. |

| Cost | High operational and maintenance costs. | Lower operational cost, requires investment in sensor tech. |

| Environmental Impact | Higher water and chemical consumption, waste generation. | Reduced water use and chemical additives, less waste. |

| Output Quality | Concentrates varying in grade, depends on processing stages. | Consistent sorting improves feed grade for downstream processing. |

| Flexibility | Adaptable to various ore types but less selective. | Highly selective, suitable for complex or low-grade ores. |

Introduction to Mineral Processing and Sensor-based Sorting

Mineral processing involves the physical and chemical methods used to extract valuable minerals from ore, enhancing ore grade and separating waste material. Sensor-based sorting utilizes advanced technologies such as X-ray, near-infrared, and optical sensors to identify and separate ore particles based on their properties, enabling more precise and efficient sorting. This technology reduces energy consumption and improves recovery rates compared to traditional mineral processing techniques.

Traditional Mineral Processing Techniques

Traditional mineral processing techniques such as crushing, grinding, flotation, and gravity separation remain foundational in ore beneficiation, ensuring effective liberation of valuable minerals from gangue. These methods rely on physical and chemical properties like particle size, density, and surface chemistry to concentrate ores before further refining. While sensor-based sorting offers targeted pre-concentration and waste rejection, conventional techniques continue to dominate due to their scalability and established operational frameworks in mining.

Principles of Sensor-based Sorting Technology

Sensor-based sorting technology separates ore particles by detecting physical and chemical properties such as color, density, and electromagnetic response using sensors including X-ray transmission, near-infrared, and laser-induced fluorescence. This method enables rapid and precise identification of valuable minerals from waste by analyzing surface characteristics and internal composition without physical contact. Optimizing sensor-based sorting enhances recovery rates, reduces energy consumption, and minimizes downstream processing costs compared to traditional mineral processing techniques.

Efficiency Comparison: Throughput and Recovery Rates

Mineral processing achieves high throughput by utilizing crushing, grinding, and flotation techniques, effectively handling large ore volumes while recovering valuable minerals with recovery rates typically ranging from 85% to 95%. Sensor-based sorting enhances recovery by precisely identifying and segregating ore based on physical or chemical properties, often improving recovery rates by 5% to 10% compared to traditional methods, especially in low-grade ores. Throughput in sensor-based sorting is generally lower than conventional mineral processing but offers higher efficiency in selective ore treatment, minimizing waste and reducing downstream processing costs.

Environmental Impact: Water and Energy Consumption

Mineral processing typically requires significant water usage for ore slurry preparation, flotation, and washing, often leading to high water consumption and wastewater generation. Sensor-based sorting drastically reduces water use by enabling dry pre-concentration, lowering both water consumption and energy requirements by minimizing ore volume before subsequent processing. This reduction in water and energy demands contributes to a smaller environmental footprint, promoting more sustainable mining operations.

Economic Considerations and Cost-effectiveness

Mineral processing techniques often require significant capital investment and operational costs due to extensive grinding, crushing, and chemical treatments, impacting overall economic feasibility. Sensor-based sorting offers cost-effective alternatives by reducing tailings and enhancing ore grade early in the process, leading to lower energy consumption and reagent usage. Implementing sensor-based sorting can improve cash flow by increasing throughput efficiency and decreasing downstream processing expenses in mining operations.

Ore Grade and Feed Characteristics: Suitability for Each Method

Mineral processing techniques excel with consistent ore grades and finely divided feed materials, enabling efficient liberation of valuable minerals through crushing, grinding, and separation methods. Sensor-based sorting is highly effective for variable ore grades and coarse feed, using real-time data from X-ray, optical, or electromagnetic sensors to selectively separate valuable particles from waste. Ore grade heterogeneity and feed size distribution determine the optimal method, with mineral processing favored for homogenous, fine-grained ores and sensor-based sorting preferred for heterogenous, coarse, and complex feed material.

Technological Advancements in Sorting Sensors

Technological advancements in sorting sensors have revolutionized mineral processing by enhancing the precision and efficiency of ore separation. High-resolution X-ray transmission (XRT) sensors, near-infrared (NIR) spectroscopy, and laser-induced breakdown spectroscopy (LIBS) enable real-time analysis of mineral composition, facilitating more accurate sensor-based sorting. These innovations reduce energy consumption, minimize waste, and improve recovery rates compared to traditional beneficiation methods.

Integration of Sensor-based Sorting in Existing Processing Plants

Sensor-based sorting enhances existing mineral processing plants by selectively separating ore particles based on physical and chemical properties, increasing feed grade and reducing downstream processing costs. Integration requires compatible sensor technologies such as X-ray, laser, or hyperspectral imaging tailored to specific ore characteristics and plant throughput. Optimizing sensor calibration and real-time data analytics ensures seamless operation while maximizing recovery rates and minimizing energy consumption in mineral beneficiation workflows.

Future Trends in Mineral Processing and Digital Sorting Technologies

Future trends in mineral processing emphasize the integration of sensor-based sorting technologies to enhance ore grade control and reduce energy consumption. Advanced sensors utilizing X-ray, near-infrared, and laser-induced breakdown spectroscopy enable precise real-time separation of valuable minerals from waste, optimizing grinding and flotation efficiencies. Digital sorting advances support sustainable mining by minimizing tailings and boosting yield through automated, data-driven decision-making systems.

Related Important Terms

Liberation Efficiency

Mineral processing techniques enhance liberation efficiency by mechanically breaking down ore to separate valuable minerals from gangue, achieving finer particle sizes for improved recovery rates. Sensor-based sorting selectively identifies and separates ore fragments based on physical or chemical properties, offering higher liberation efficiency by targeting only liberated minerals and reducing the processing of waste material.

Grade Engineering

Grade engineering through mineral processing enhances ore quality by utilizing crushing, grinding, and beneficiation techniques to concentrate valuable minerals. Sensor-based sorting improves grade control by rapidly identifying and separating particles with different mineral compositions, increasing efficiency and reducing processing costs.

Pre-concentration

Mineral processing techniques focus on liberating valuable minerals through grinding and classification, while sensor-based sorting enables precise pre-concentration by selectively separating ore particles based on physical and chemical properties detected by sensors. Pre-concentration via sensor-based sorting reduces downstream processing costs by rejecting waste early, increasing overall plant efficiency and ore grade.

Sensor Fusion (Multi-sensor Sorting)

Sensor fusion in mineral processing integrates data from multiple sensors such as X-ray, near-infrared, and optical imaging to enhance the accuracy and efficiency of sensor-based sorting technologies. This multi-sensor sorting approach enables real-time, precise identification and separation of valuable minerals, reducing waste and improving recovery rates compared to traditional single-sensor methods.

Hyperspectral Imaging

Hyperspectral imaging in mineral processing enables precise identification and separation of ore minerals by capturing detailed spectral signatures beyond visible wavelengths, enhancing ore grade control and recovery rates. Sensor-based sorting using hyperspectral data allows real-time, non-destructive analysis that improves efficiency and reduces processing costs compared to traditional bulk mineral processing methods.

X-ray Transmission Sorting (XRT)

X-ray Transmission Sorting (XRT) in mineral processing enhances ore grade by differentiating minerals based on their atomic density, enabling precise separation without the need for prior crushing or chemical treatment. This sensor-based sorting technology reduces processing costs and environmental impact by increasing yield efficiency and minimizing waste compared to traditional mineral processing methods.

Automated Ore Sorting

Automated ore sorting in mineral processing enhances efficiency by using sensor-based sorting technologies such as X-ray, near-infrared, and laser sensors to distinguish ore from waste with high precision. This method reduces energy consumption, increases recovery rates, and minimizes downstream processing costs compared to traditional crushing and grinding techniques.

Digital Orebody Modeling

Mineral processing enhances ore recovery through crushing, grinding, and separation techniques, while sensor-based sorting improves efficiency by digitally analyzing and segregating ore based on real-time sensor data integrated into digital orebody modeling. Advanced digital orebody models enable precise spatial mapping and grade distribution, optimizing both mineral processing operations and sensor-based sorting for increased yield and reduced waste.

Real-time Mineral Analytics

Real-time mineral analytics in mineral processing utilize advanced sensor-based sorting technologies to enhance ore characterization and improve separation efficiency by detecting and classifying minerals at high speeds. This approach reduces operational costs, increases recovery rates, and enables adaptive process control through continuous data feedback and precise mineral identification.

Deep Learning Ore Classification

Deep learning ore classification enhances mineral processing efficiency by enabling precise identification and separation of ore types through sensor data analysis, significantly improving recovery rates and reducing waste. Sensor-based sorting integrated with advanced neural networks processes multi-modal data streams, optimizing ore quality control and enabling real-time adaptive sorting in complex mining operations.

Mineral Processing vs Sensor-based Sorting Infographic

industrydif.com

industrydif.com