Room and pillar mining involves creating a network of rooms supported by pillars of untouched material to maintain structural integrity, offering high recovery rates in flat-lying ore deposits. Borehole mining uses high-pressure water jets to extract ore through boreholes, minimizing surface disturbance and allowing access to deep or complex deposits without extensive underground infrastructure. Choosing between these methods depends on orebody geometry, environmental impact considerations, and economic factors.

Table of Comparison

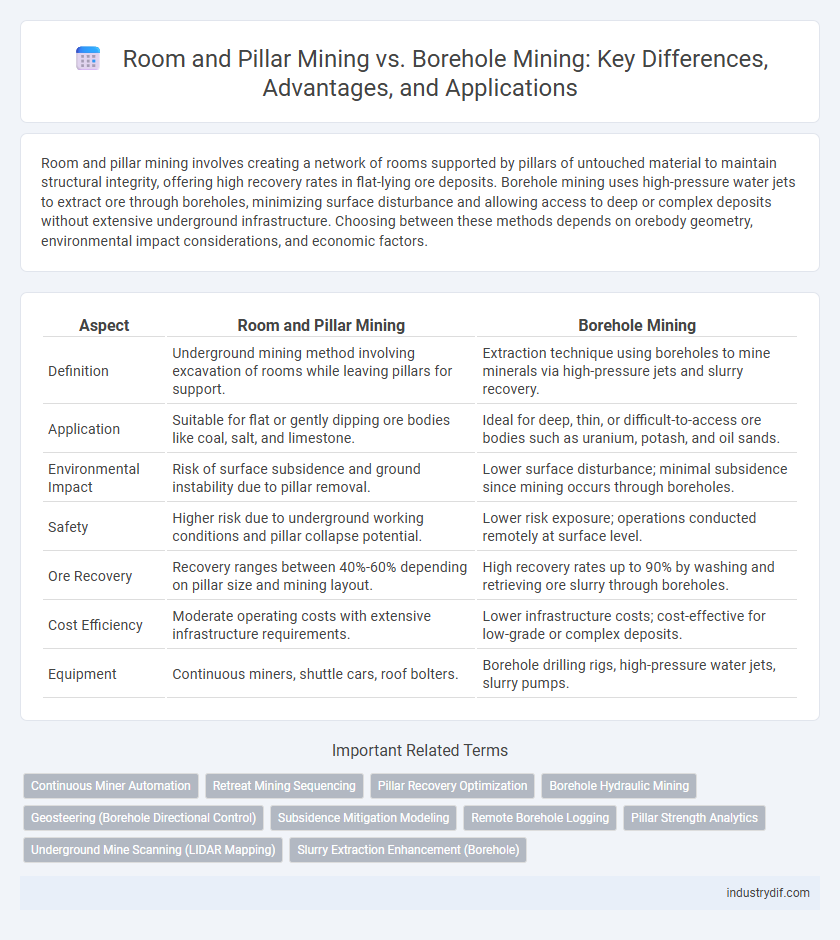

| Aspect | Room and Pillar Mining | Borehole Mining |

|---|---|---|

| Definition | Underground mining method involving excavation of rooms while leaving pillars for support. | Extraction technique using boreholes to mine minerals via high-pressure jets and slurry recovery. |

| Application | Suitable for flat or gently dipping ore bodies like coal, salt, and limestone. | Ideal for deep, thin, or difficult-to-access ore bodies such as uranium, potash, and oil sands. |

| Environmental Impact | Risk of surface subsidence and ground instability due to pillar removal. | Lower surface disturbance; minimal subsidence since mining occurs through boreholes. |

| Safety | Higher risk due to underground working conditions and pillar collapse potential. | Lower risk exposure; operations conducted remotely at surface level. |

| Ore Recovery | Recovery ranges between 40%-60% depending on pillar size and mining layout. | High recovery rates up to 90% by washing and retrieving ore slurry through boreholes. |

| Cost Efficiency | Moderate operating costs with extensive infrastructure requirements. | Lower infrastructure costs; cost-effective for low-grade or complex deposits. |

| Equipment | Continuous miners, shuttle cars, roof bolters. | Borehole drilling rigs, high-pressure water jets, slurry pumps. |

Overview of Room and Pillar Mining

Room and Pillar Mining is a widely used underground mining method involving the excavation of numerous rooms while leaving pillars of untouched material to support the roof. This technique is particularly effective for extracting coal, salt, and potash deposits by providing a stable environment with high safety standards. Efficiency in resource recovery and minimizing surface subsidence distinguishes Room and Pillar Mining from Borehole Mining, which primarily utilizes remote drilling to access minerals without extensive underground excavation.

Fundamentals of Borehole Mining

Borehole mining involves extracting minerals through drilled boreholes using high-pressure water jets to dislodge material and slurry pumps to bring the ore to the surface. Unlike Room and Pillar Mining, which requires extensive underground tunnels and leaves pillars of ore for structural support, Borehole Mining minimizes surface disturbance and reduces the need for large underground excavations. This method is particularly effective for extracting ore bodies in difficult-to-access locations or beneath water bodies, enhancing operational safety and environmental sustainability.

Key Differences Between Mining Methods

Room and Pillar Mining involves creating a network of rooms separated by pillars of untouched material to support the roof, primarily used for flat-lying ore bodies. Borehole Mining extracts minerals through drilled boreholes using high-pressure water jets, allowing underground extraction without conventional tunnels. Key differences include the physical mining approach, with Room and Pillar focusing on direct access and structural support, while Borehole Mining relies on remote, fluid-based extraction suitable for deep or inaccessible deposits.

Geological Conditions Suited for Each Method

Room and pillar mining is best suited for flat-lying, shallow to moderately deep ore bodies with competent rock that supports stable pillars and roof conditions. Borehole mining excels in irregular, steeply dipping, or deeply buried ore deposits where traditional mining is impractical, allowing for remote extraction through drilled boreholes. Geological factors such as ore thickness, rock strength, and deposit geometry critically determine the optimal method, with room and pillar favoring uniform strata and borehole mining accommodating complex or inaccessible formations.

Equipment and Technology Used

Room and pillar mining employs continuous miners, shuttle cars, and roof bolters to extract ore while maintaining structural stability with pillars, utilizing tunnel-boring machines for ventilation and material transport. Borehole mining uses high-pressure water jets and remote-controlled robotic tools to dissolve and pump ore slurry through boreholes, minimizing surface disturbance through specialized submersible pumps and hydraulic excavators. Advanced automation and monitoring systems enhance operational efficiency and safety in both mining techniques.

Operational Procedures in Room and Pillar Mining

Room and pillar mining involves the systematic excavation of horizontal rooms supported by pillars of unmined material, ensuring stability throughout the operation. The process requires precise drilling, blasting, loading, and hauling equipment, while continuously monitoring pillar integrity and ground conditions to prevent collapse. Ventilation systems and material transport pathways are integral to maintaining a safe and efficient extraction environment within the mine.

Borehole Mining Process Steps

Borehole mining involves remotely extracting minerals through drilled boreholes using high-pressure water jets to break ore into a slurry for surface pumping. The process begins with drilling a borehole to the ore body, followed by inserting a mining tool that cuts or loosens the material. After loosening, the slurry is transported to the surface via a hydraulic lifting system, optimizing safety and minimizing surface disturbance compared to room and pillar mining.

Safety Considerations in Both Methods

Room and pillar mining offers enhanced stability by leaving pillars of ore to support the roof, reducing collapse risks and providing safer working conditions underground. Borehole mining minimizes direct human exposure to hazardous environments by remotely extracting ore through high-pressure jets, significantly lowering the risk of accidents and exposure to toxic gases. Both methods require rigorous monitoring for structural integrity and gas levels, but room and pillar mining demands more extensive ventilation and ground support systems to ensure worker safety.

Economic and Environmental Impacts

Room and pillar mining offers cost efficiency through selective resource extraction and reduced land surface disruption, minimizing environmental remediation expenses. Borehole mining, although typically more expensive due to specialized equipment and limited resource access, significantly lowers environmental impact by eliminating surface disturbance and reducing waste generation. Economically, room and pillar mining supports higher immediate output while borehole mining provides sustainable benefits by preserving surrounding ecosystems and reducing long-term reclamation costs.

Applications and Industry Case Studies

Room and pillar mining is extensively used in coal and salt extraction due to its stability and efficiency in maintaining underground structural integrity, particularly in large-scale operations such as the U.S. Appalachian coalfields. Borehole mining finds its niche in the recovery of placer deposits and underwater minerals, exemplified by projects in offshore diamond mining in Namibia, offering minimal surface disturbance and targeted extraction. Industry case studies demonstrate room and pillar mining's dominance in hard rock mining sectors, while borehole mining is preferred for inaccessible or environmentally sensitive sites, highlighting their complementary roles across mining applications.

Related Important Terms

Continuous Miner Automation

Room and Pillar Mining uses automated continuous miners to enhance extraction efficiency and safety by remotely controlling the cutting and material handling processes, reducing human exposure to hazardous conditions. Borehole Mining, while effective for selective mineral retrieval in difficult-to-access locations, lacks integrated continuous miner automation, resulting in lower operational continuity and automation potential compared to Room and Pillar methods.

Retreat Mining Sequencing

Retreat mining sequencing in room and pillar mining involves systematically extracting pillars to maximize resource recovery while maintaining ground stability, contrasting with borehole mining where material is removed through drilled holes without creating a traditional support system. Room and pillar retreat sequencing requires careful planning to prevent roof collapse, whereas borehole mining offers flexibility with minimal surface disturbance but limited control over ore body geometry.

Pillar Recovery Optimization

Pillar recovery optimization in Room and Pillar mining enhances extraction rates by strategically designing pillar sizes and employing controlled extraction methods to maintain roof stability while maximizing ore recovery. Borehole mining offers targeted ore retrieval with minimal surface disruption but lacks the extensive pillar recovery potential found in Room and Pillar operations.

Borehole Hydraulic Mining

Borehole hydraulic mining uses high-pressure water jets to fragment and extract minerals through drilled boreholes, enabling efficient resource recovery from hard-to-reach or structurally unstable ore bodies. Unlike Room and Pillar Mining, which relies on maintaining stable pillars to support underground voids, borehole hydraulic mining minimizes surface subsidence and reduces the need for extensive underground infrastructure.

Geosteering (Borehole Directional Control)

Room and Pillar Mining offers stable roof control by leaving pillars in place, yet lacks precision in underground navigation, whereas Borehole Mining leverages advanced geosteering technology to optimize borehole directional control, enhancing ore extraction accuracy and minimizing environmental impact. Real-time downhole sensors and geospatial data integration enable precise adjustments in borehole trajectory, significantly improving resource recovery efficiency compared to conventional mining methods.

Subsidence Mitigation Modeling

Room and Pillar Mining employs a systematic removal of ore while leaving pillars of untouched material to support the roof, significantly reducing ground subsidence risks through effective load distribution modeling. Borehole Mining minimizes surface disturbance by extracting ore via pressurized jets and slurry pumping, which requires advanced subsidence mitigation modeling to predict aquifer interactions and ground deformation accurately.

Remote Borehole Logging

Room and Pillar Mining involves extracting minerals while leaving pillars to support the roof, creating accessible underground rooms, whereas Borehole Mining utilizes pressurized jets to recover ore through boreholes without extensive excavation. Remote Borehole Logging enhances Borehole Mining by providing precise subsurface data via downhole sensors, optimizing ore recovery and improving operational safety through real-time geological monitoring.

Pillar Strength Analytics

Pillar strength analytics in room and pillar mining involve assessing the load-bearing capacity of coal or mineral pillars to prevent collapse and ensure mine stability, utilizing methods like numerical modeling and empirical formulas such as the Mark-Bieniawski equation. Borehole mining lacks pillar structures, relying instead on fluid jets and remote recovery, making pillar strength analysis irrelevant but emphasizing cavity stability and hydraulic pressure monitoring instead.

Underground Mine Scanning (LIDAR Mapping)

Room and Pillar Mining benefits from LIDAR mapping by enabling precise underground mine scanning to create detailed 3D models of excavated rooms and pillars, improving structural analysis and safety monitoring. Borehole Mining leverages LIDAR data integrated with borehole imaging to enhance subsurface mapping accuracy, optimizing slurry extraction paths and minimizing resource wastage.

Slurry Extraction Enhancement (Borehole)

Borehole mining significantly enhances slurry extraction by using high-pressure water jets to disintegrate mineral deposits and transport slurry through boreholes, enabling precise targeting in difficult-to-reach ore bodies. Room and pillar mining, while effective for stable ore recovery, lacks the fluid extraction efficiency and minimal surface disruption provided by borehole slurry extraction techniques.

Room and Pillar Mining vs Borehole Mining Infographic

industrydif.com

industrydif.com