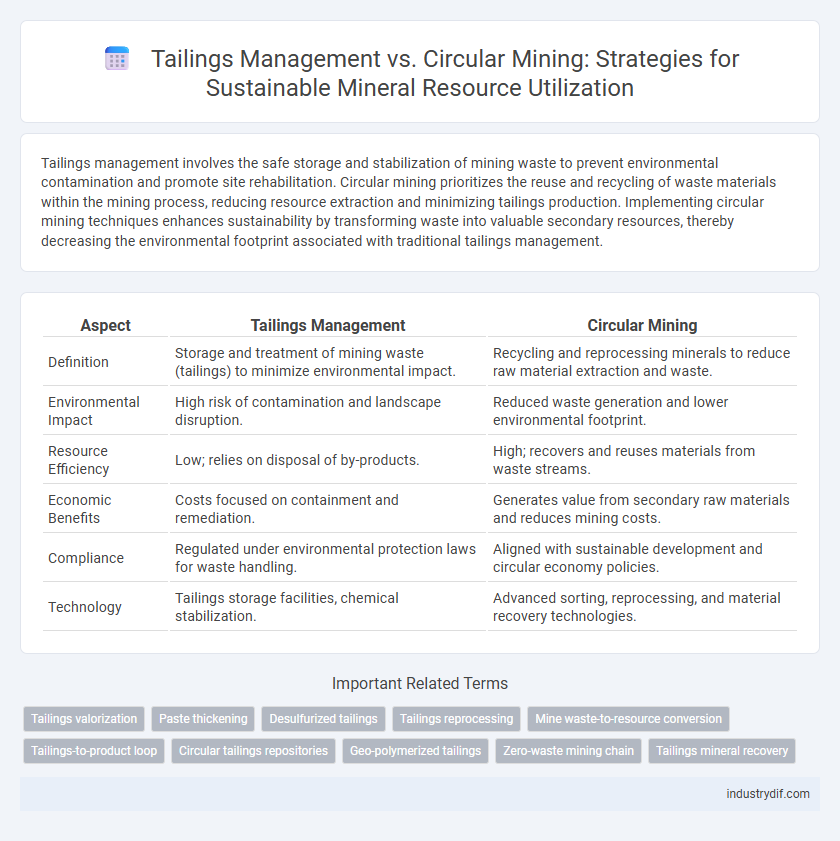

Tailings management involves the safe storage and stabilization of mining waste to prevent environmental contamination and promote site rehabilitation. Circular mining prioritizes the reuse and recycling of waste materials within the mining process, reducing resource extraction and minimizing tailings production. Implementing circular mining techniques enhances sustainability by transforming waste into valuable secondary resources, thereby decreasing the environmental footprint associated with traditional tailings management.

Table of Comparison

| Aspect | Tailings Management | Circular Mining |

|---|---|---|

| Definition | Storage and treatment of mining waste (tailings) to minimize environmental impact. | Recycling and reprocessing minerals to reduce raw material extraction and waste. |

| Environmental Impact | High risk of contamination and landscape disruption. | Reduced waste generation and lower environmental footprint. |

| Resource Efficiency | Low; relies on disposal of by-products. | High; recovers and reuses materials from waste streams. |

| Economic Benefits | Costs focused on containment and remediation. | Generates value from secondary raw materials and reduces mining costs. |

| Compliance | Regulated under environmental protection laws for waste handling. | Aligned with sustainable development and circular economy policies. |

| Technology | Tailings storage facilities, chemical stabilization. | Advanced sorting, reprocessing, and material recovery technologies. |

Introduction to Tailings Management and Circular Mining

Tailings management involves the safe storage and handling of mining waste materials to minimize environmental impact and ensure regulatory compliance. Circular mining emphasizes resource efficiency by recovering valuable materials from tailings and waste streams, promoting sustainable mineral lifecycle practices. Integrating circular mining principles into tailings management reduces raw material consumption and mitigates long-term ecological risks.

Defining Tailings: Challenges and Impacts

Tailings, the finely ground waste materials left after ore extraction, pose significant environmental challenges due to their toxic chemical content and large volumes. Inefficient tailings management can lead to soil contamination, water pollution, and ecosystem disruption, impacting local communities and biodiversity. Circular mining aims to minimize tailings by reprocessing waste materials, recovering valuable minerals, and promoting sustainable resource use, thereby reducing environmental footprints and enhancing operational efficiency.

Principles of Circular Mining in Modern Industry

Circular mining principles emphasize resource efficiency, waste reduction, and environmental sustainability by transforming tailings into secondary raw materials. Modern industry adopts innovative technologies such as mineral recovery, residue reprocessing, and eco-friendly extraction methods to minimize tailings impact and promote closed-loop resource cycles. Implementing circular mining reduces the ecological footprint of mining operations while enhancing economic value through material reuse and conservation.

Tailings Storage Solutions: Current Best Practices

Tailings storage solutions in mining prioritize engineered dams, dry stacking, and paste tailings methods to enhance stability and reduce environmental risks. Current best practices emphasize real-time monitoring systems, improved water recovery, and progressive rehabilitation techniques to minimize footprint and prevent contamination. Innovations in geotechnical design and waste valorization contribute to safer, more sustainable tailings management aligned with circular mining principles.

Resource Recovery: Turning Waste into Value

Tailings management traditionally focuses on the safe storage and containment of mining residues to prevent environmental contamination, often resulting in limited resource recovery. Circular mining promotes the recovery of valuable metals and minerals from tailings by employing advanced technologies such as bioleaching, flotation, and hydrometallurgy, transforming waste into secondary raw materials. This approach enhances resource efficiency, reduces the need for primary extraction, and supports sustainable mining practices by closing material loops.

Environmental Risks: Comparing Tailings to Circular Approaches

Tailings management poses environmental risks such as soil and water contamination from heavy metals and toxic chemicals, leading to ecosystem degradation and long-term pollution. Circular mining minimizes these risks by promoting material reuse, waste reduction, and closed-loop resource recovery, thereby decreasing the volume of tailings produced. Emphasizing circular approaches supports sustainable mining practices, mitigates hazardous waste generation, and enhances environmental protection.

Innovative Technologies in Tailings Reprocessing

Innovative technologies in tailings reprocessing enhance resource recovery by extracting valuable minerals from mining waste, reducing environmental impact and improving sustainability. Advanced methods such as bioleaching, sensor-based sorting, and flotation optimization enable circular mining practices by transforming tailings into secondary ore sources. These innovations contribute to the efficient management of tailings storage facilities while promoting resource conservation within the mining industry.

Regulatory Frameworks for Sustainable Mining

Regulatory frameworks for sustainable mining increasingly emphasize tailings management to prevent environmental contamination and ensure structural stability through strict monitoring and reporting requirements. Circular mining policies promote resource recovery and waste minimization by mandating the reuse of tailings and integrating recycled materials into production processes, aligning with global sustainability goals. Compliance with these regulations drives innovation in tailings reuse technologies and fosters a shift towards closed-loop mining systems that reduce ecological footprints.

Economic Benefits of Circular Mining Models

Circular mining models enhance economic benefits by minimizing waste through the reuse and recycling of tailings, reducing the costs associated with tailings storage facilities and environmental remediation. These models create value from by-products, generating additional revenue streams and improving resource efficiency. Emphasizing closed-loop processes supports sustainable operations and long-term profitability in the mining sector.

Future Trends: Integrating Circular Economy into Tailings Management

Future trends in tailings management focus on integrating circular economy principles to reduce environmental impact and enhance resource recovery. Advanced technologies promote the reutilization of tailings materials, transforming waste into valuable secondary raw materials while minimizing hazardous residue. This shift supports sustainable mining operations by closing material loops and improving overall efficiency.

Related Important Terms

Tailings valorization

Tailings valorization transforms mining waste into valuable resources by recovering metals, minerals, and construction materials, reducing environmental impact and storage costs. Circular mining emphasizes sustainable resource use by integrating tailings valorization into closed-loop systems, enhancing material efficiency and minimizing waste footprint.

Paste thickening

Paste thickening enhances tailings management by reducing water content and increasing solids concentration, enabling safer storage and minimizing environmental impact. Circular mining leverages paste thickening technology to recycle tailings as backfill material, promoting sustainable resource use and reducing waste.

Desulfurized tailings

Desulfurized tailings in mining reduce environmental hazards by minimizing sulfur compounds that cause acid mine drainage, enabling safer waste storage and potential reuse. Circular mining promotes the recycling of these treated tailings into construction materials or backfill, enhancing resource efficiency and reducing ecological impact.

Tailings reprocessing

Tailings reprocessing transforms mining waste into valuable resources by extracting residual minerals, reducing environmental impact and storage risks compared to conventional tailings management. Circular mining emphasizes sustainable resource use by integrating tailings reprocessing to minimize waste, improve recovery rates, and promote closed-loop material cycles within the mining industry.

Mine waste-to-resource conversion

Tailings management involves safely storing and isolating mine waste to minimize environmental impact, whereas circular mining emphasizes transforming mine waste into valuable resources through recycling and reprocessing technologies. Advancements in waste-to-resource conversion enable extraction of metals like copper, gold, and rare earth elements from tailings, promoting sustainable mining practices and reducing raw ore dependency.

Tailings-to-product loop

Tailings management involves the safe storage and treatment of mining waste to minimize environmental impact, while circular mining emphasizes the reintegration of tailings into the production cycle to recover valuable materials. The tailings-to-product loop enhances resource efficiency by converting waste into inputs for new extraction processes, reducing the need for fresh raw materials and lowering environmental footprints.

Circular tailings repositories

Circular tailings repositories transform mining waste into reusable resources by integrating advanced recycling technologies and sustainable design principles. This approach reduces environmental impact, promotes resource efficiency, and supports the transition toward zero-waste mining operations through continuous material recovery.

Geo-polymerized tailings

Geo-polymerized tailings offer an innovative solution in tailings management by transforming mining waste into stable, reusable materials, reducing environmental hazards and promoting sustainable resource utilization. Circular mining leverages geo-polymerization techniques to minimize waste generation, enhance material recovery, and support a closed-loop system that prioritizes ecological balance and economic efficiency.

Zero-waste mining chain

Tailings management aims to safely store and remediate mining waste materials, while circular mining emphasizes resource recovery and reuse to minimize environmental impact. Implementing a zero-waste mining chain integrates advanced processing technologies and recycling methods to transform tailings into secondary raw materials, promoting sustainability and reducing landfill dependency.

Tailings mineral recovery

Tailings management focuses on the safe disposal and environmental containment of mining waste, while circular mining emphasizes the recovery and reuse of valuable minerals from tailings to reduce resource depletion. Advanced mineral recovery techniques from tailings, such as flotation and hydrometallurgical processes, enhance sustainability by extracting residual metals like copper, gold, and rare earth elements.

Tailings management vs Circular mining Infographic

industrydif.com

industrydif.com