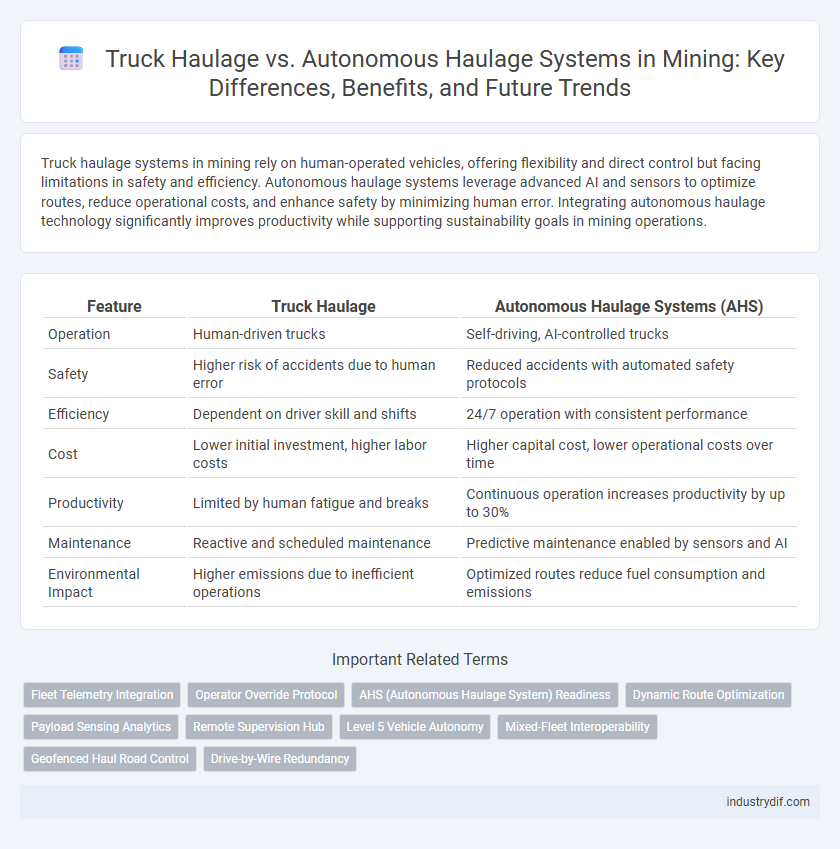

Truck haulage systems in mining rely on human-operated vehicles, offering flexibility and direct control but facing limitations in safety and efficiency. Autonomous haulage systems leverage advanced AI and sensors to optimize routes, reduce operational costs, and enhance safety by minimizing human error. Integrating autonomous haulage technology significantly improves productivity while supporting sustainability goals in mining operations.

Table of Comparison

| Feature | Truck Haulage | Autonomous Haulage Systems (AHS) |

|---|---|---|

| Operation | Human-driven trucks | Self-driving, AI-controlled trucks |

| Safety | Higher risk of accidents due to human error | Reduced accidents with automated safety protocols |

| Efficiency | Dependent on driver skill and shifts | 24/7 operation with consistent performance |

| Cost | Lower initial investment, higher labor costs | Higher capital cost, lower operational costs over time |

| Productivity | Limited by human fatigue and breaks | Continuous operation increases productivity by up to 30% |

| Maintenance | Reactive and scheduled maintenance | Predictive maintenance enabled by sensors and AI |

| Environmental Impact | Higher emissions due to inefficient operations | Optimized routes reduce fuel consumption and emissions |

Introduction to Truck Haulage and Autonomous Haulage Systems

Truck haulage involves manually operated trucks transporting ore and waste material in mining operations, relying heavily on skilled drivers and real-time decision-making. Autonomous haulage systems (AHS) utilize advanced robotics, GPS, and AI to enable driverless trucks that optimize route efficiency, improve safety, and reduce operational costs. Integration of AHS in mining improves productivity by minimizing downtime and allowing precise control over haulage processes compared to traditional truck haulage methods.

Evolution of Haulage in the Mining Industry

Truck haulage in mining has traditionally relied on human-operated vehicles, limiting efficiency and safety. Autonomous haulage systems (AHS) have revolutionized mining by using advanced robotics and AI to enhance productivity, reduce operational costs, and improve safety standards. The evolution from manual truck haulage to AHS reflects the industry's shift towards digital transformation and sustainable mining practices.

Key Components of Traditional Truck Haulage

Traditional truck haulage in mining relies on diesel-powered haul trucks, skilled operators, and manual dispatch control systems to transport ore and waste material efficiently. Key components include rugged, high-capacity trucks designed for harsh terrain, driver cabins equipped for safety and ergonomics, and fleet management software that monitors vehicle location, fuel consumption, and maintenance schedules. This conventional setup prioritizes human oversight and mechanical reliability to optimize haulage productivity and operational flexibility.

Technology Overview: Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) utilize advanced technologies such as LiDAR, GPS, and real-time data analytics to optimize mining truck operations, enhancing efficiency and safety. These systems enable trucks to operate without human drivers by following pre-programmed routes and adjusting to dynamic conditions using AI-powered sensors and machine learning algorithms. Integration of AHS reduces operational costs and improves productivity through continuous operation and precise fleet management.

Operational Efficiency: Manual vs. Autonomous Haulage

Manual truck haulage relies heavily on human operators, which can lead to variability in operational efficiency due to fatigue, skill levels, and reaction times. Autonomous haulage systems (AHS) use advanced sensors, AI, and GPS technology to optimize routes, reduce turnaround times, and maintain consistent speeds, significantly enhancing productivity. Studies show AHS can increase haulage cycle times by up to 20%, reduce fuel consumption by 10-15%, and lower operational downtime compared to manual haulage.

Safety Considerations in Haulage Operations

Truck haulage in mining involves human operators, increasing risks related to driver fatigue, human error, and limited visibility in hazardous environments. Autonomous haulage systems (AHS) enhance safety by eliminating human error through advanced sensors, real-time monitoring, and predictive analytics, reducing collision and spill incidents. Implementing AHS also minimizes exposure to dangerous conditions, improving overall operational safety and compliance with mine safety regulations.

Cost Analysis: Capital and Operational Expenditure

Truck haulage systems typically involve lower initial capital expenditure but higher operational costs due to fuel consumption, driver wages, and maintenance. Autonomous haulage systems demand significant upfront investment in advanced technology, sensors, and software integration, yet they offer substantial reductions in operational expenditure through improved fuel efficiency, lower labor costs, and optimized maintenance schedules. Over the long term, autonomous haulage systems demonstrate a favorable total cost of ownership by minimizing downtime and enhancing productivity, outweighing their higher capital costs.

Environmental Impact: Fuel Consumption and Emissions

Autonomous haulage systems (AHS) in mining significantly reduce fuel consumption by optimizing routes, maintaining consistent speeds, and minimizing unnecessary idling, leading to lower greenhouse gas emissions compared to traditional truck haulage. Electric or hybrid autonomous trucks further decrease environmental impact by cutting diesel reliance and reducing particulate matter emissions. Implementing AHS contributes to compliance with stringent environmental regulations and supports sustainable mining practices through efficient energy use and reduced carbon footprints.

Workforce Implications: Skills and Employment Shifts

Truck haulage relies heavily on skilled drivers, creating ongoing demand for trained personnel capable of navigating complex mining terrains. Autonomous haulage systems (AHS) shift workforce needs towards roles in remote operation, system monitoring, and data analysis, requiring advanced technical expertise and continuous digital skills development. This transition drives employment shifts within mining companies, emphasizing upskilling existing workers and recruiting talent adept in robotics, AI, and cybersecurity.

Future Trends in Mining Haulage Technologies

Autonomous haulage systems (AHS) are rapidly transforming mining truck haulage by enhancing safety, increasing operational efficiency, and reducing labor costs through advanced AI and GPS technologies. Future trends indicate a significant shift toward integrating machine learning algorithms and real-time data analytics to optimize route selection and fuel consumption in both autonomous and conventional trucks. Mining companies are investing heavily in smart haulage fleets equipped with sensor fusion and edge computing to enable predictive maintenance and minimize downtime, driving the next generation of haulage productivity.

Related Important Terms

Fleet Telemetry Integration

Fleet telemetry integration in autonomous haulage systems optimizes real-time monitoring of truck position, speed, and load capacity, significantly enhancing operational efficiency compared to traditional truck haulage. Advanced data analytics and IoT sensors in autonomous fleets enable predictive maintenance and route optimization, reducing downtime and fuel consumption across mining operations.

Operator Override Protocol

Operator override protocols in truck haulage rely heavily on human intervention to ensure safety and operational control, whereas autonomous haulage systems integrate advanced sensor fusion and AI-driven decision-making to enable seamless manual override only in critical scenarios. These protocols prioritize real-time data analytics and fail-safe mechanisms to minimize downtime and enhance safety compliance during operator interventions.

AHS (Autonomous Haulage System) Readiness

Autonomous Haulage Systems (AHS) demonstrate superior readiness in mining, offering increased operational efficiency, reduced labor costs, and enhanced safety compared to traditional truck haulage. Advanced AHS technologies integrate real-time data analytics and AI-driven fleet management, enabling seamless coordination and minimizing downtime in large-scale mining operations.

Dynamic Route Optimization

Autonomous haulage systems enhance mining efficiency through dynamic route optimization, leveraging real-time data and AI to adjust truck paths and minimize cycle times, fuel consumption, and wear. Traditional truck haulage relies on static routes and human decision-making, which often leads to suboptimal transport routes and increased operational costs.

Payload Sensing Analytics

Payload sensing analytics in autonomous haulage systems enable real-time monitoring and optimization of load weights, enhancing operational efficiency and reducing overloading risks compared to traditional truck haulage. Advanced sensor integration and data analysis provide precise payload measurements, leading to improved fleet management and fuel consumption in mining operations.

Remote Supervision Hub

Remote Supervision Hubs in autonomous haulage systems enable centralized monitoring and control of fleets, significantly improving operational efficiency and safety compared to traditional truck haulage. By integrating real-time data analytics and AI-driven decision-making, these hubs reduce downtime, optimize route planning, and enhance load management in mining operations.

Level 5 Vehicle Autonomy

Level 5 vehicle autonomy in mining haulage systems enables fully autonomous trucks to operate without human intervention, improving safety, efficiency, and operational consistency compared to traditional truck haulage. Autonomous haulage systems reduce operational costs by optimizing routes, minimizing fuel consumption, and enabling 24/7 mining operations under harsh environmental conditions.

Mixed-Fleet Interoperability

Mixed-fleet interoperability in mining enables seamless integration between traditional truck haulage and autonomous haulage systems, optimizing operational efficiency and reducing downtime. Enhanced communication protocols and centralized fleet management platforms ensure coordinated task allocation, safety compliance, and real-time data sharing across both manned and autonomous vehicles.

Geofenced Haul Road Control

Geofenced haul road control enhances safety and efficiency by restricting autonomous haulage systems to designated routes, minimizing deviations and collision risks compared to traditional truck haulage. This technology leverages GPS and sensor data to create virtual boundaries, enabling precise navigation and real-time monitoring within mining sites.

Drive-by-Wire Redundancy

Drive-by-wire redundancy in autonomous haulage systems enhances safety and operational reliability by employing multiple independent control pathways that ensure continuous vehicle function despite system failures. Compared to traditional truck haulage, this advanced redundancy minimizes downtime and reduces human error, significantly improving haulage efficiency and fleet availability in mining operations.

Truck haulage vs Autonomous haulage systems Infographic

industrydif.com

industrydif.com