Cut and fill mining is a selective underground mining method that involves excavating horizontal slices in a stope, then backfilling the void with waste material to provide ground support. Room and pillar mining creates a network of open rooms supported by pillars of untouched material, allowing for efficient extraction in flat-lying deposits. While cut and fill offers greater safety and ore recovery in irregular ore bodies, room and pillar is more cost-effective for extensive, flat deposits with consistent geology.

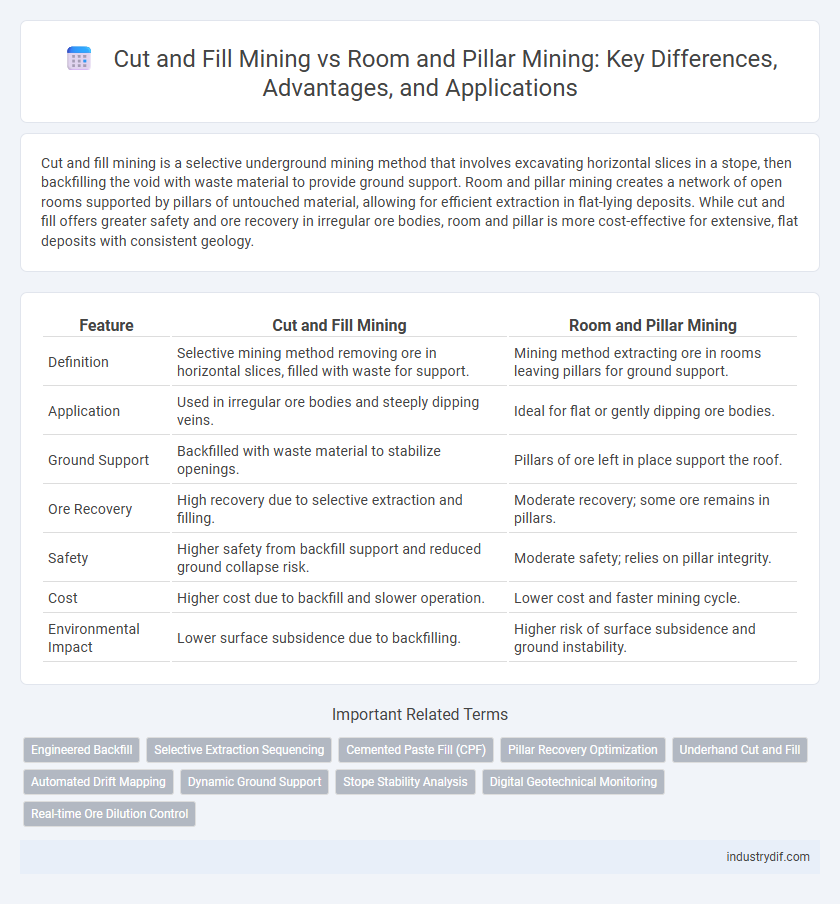

Table of Comparison

| Feature | Cut and Fill Mining | Room and Pillar Mining |

|---|---|---|

| Definition | Selective mining method removing ore in horizontal slices, filled with waste for support. | Mining method extracting ore in rooms leaving pillars for ground support. |

| Application | Used in irregular ore bodies and steeply dipping veins. | Ideal for flat or gently dipping ore bodies. |

| Ground Support | Backfilled with waste material to stabilize openings. | Pillars of ore left in place support the roof. |

| Ore Recovery | High recovery due to selective extraction and filling. | Moderate recovery; some ore remains in pillars. |

| Safety | Higher safety from backfill support and reduced ground collapse risk. | Moderate safety; relies on pillar integrity. |

| Cost | Higher cost due to backfill and slower operation. | Lower cost and faster mining cycle. |

| Environmental Impact | Lower surface subsidence due to backfilling. | Higher risk of surface subsidence and ground instability. |

Overview of Cut and Fill Mining

Cut and fill mining is a selective underground mining method used to extract ore from irregular or steeply dipping ore bodies by mining horizontal slices and backfilling each cut with waste rock or tailings to provide ground support. This technique allows for high ore recovery rates and increased safety in unstable ground conditions, making it suitable for precious metals like gold and silver. The method's flexibility in adapting to varied ore geometries distinguishes it from room and pillar mining, which primarily involves leaving pillars of ore to support the roof.

Overview of Room and Pillar Mining

Room and Pillar mining is a widely used underground coal and ore extraction method that involves mining horizontal passages or "rooms" while leaving behind "pillars" of untouched material to support the roof. This technique maximizes resource recovery while maintaining mine stability and worker safety, particularly in flat-lying ore bodies. The method is favored for its efficiency in extracting mineral deposits with minimal ground subsidence compared to Cut and Fill Mining.

Geological Suitability and Application

Cut and Fill Mining excels in irregular ore bodies and steeply dipping veins where ground stability and selective ore extraction are critical, making it ideal for weak or fractured rock conditions. Room and Pillar Mining suits more uniform, horizontal deposits such as coal or salt, providing efficient extraction with stable geology and minimal ground movement. Geological suitability hinges on rock strength, ore geometry, and structural integrity, guiding the choice between the highly selective cut and fill method and the more extensive, stability-focused room and pillar approach.

Mining Methodology and Processes

Cut and fill mining involves excavating ore in horizontal slices, starting from the bottom and filling the voids with waste material to provide support, allowing safe access to higher levels. Room and pillar mining extracts ore by creating a network of rooms supported by pillars of untouched material, maintaining the mine's structural integrity. The cut and fill method is often preferred for irregular ore bodies and steeply dipping deposits, while room and pillar is efficient for flat-lying, extensive ore seams.

Safety Considerations and Risks

Cut and fill mining offers enhanced safety by allowing selective ore removal and immediate backfilling, which reduces ground subsidence and supports stable tunnels. Room and pillar mining involves leaving pillars of ore to support the roof, but risks pillar failure and roof collapse if pillars are improperly sized or extraction ratios exceed safe limits. Both methods require rigorous ground control monitoring and adherence to safety protocols to mitigate hazards such as rock falls, gas buildup, and equipment entrapment.

Ore Recovery and Dilution Rates

Cut and fill mining typically achieves higher ore recovery rates, often exceeding 85%, due to selective extraction and backfilling, which helps maintain ground stability. Room and pillar mining generally exhibits lower dilution rates, commonly below 10%, because the pillars support the overhead rock, minimizing caving and waste inclusion. The choice between these methods depends on deposit geometry and desired balance between ore recovery and operational safety.

Environmental Impact Comparison

Cut and Fill Mining generates less surface disturbance by backfilling excavated areas, reducing waste rock exposure and minimizing acid mine drainage compared to Room and Pillar Mining. Room and Pillar Mining often leaves behind large volumes of waste rock on the surface, increasing habitat disruption and water contamination risks. The controlled backfill in Cut and Fill also stabilizes underground workings, lowering subsidence and environmental hazards associated with pillar failure.

Equipment and Technology Requirements

Cut and Fill Mining requires highly specialized equipment such as backhoes, loaders, and flexible ventilation systems to manage irregular ore bodies and unstable ground conditions effectively. Room and Pillar Mining relies on continuous miners, shuttle cars, and roof bolters optimized for maintaining stability in flat-lying deposits while maximizing extraction efficiency. Advanced automation and remote control technologies are increasingly integrated into both methods to enhance safety and operational precision.

Cost Analysis and Operational Efficiency

Cut and Fill Mining generally incurs higher operational costs due to extensive ground support and slower excavation rates but allows for selective ore extraction, reducing waste and improving ore recovery. Room and Pillar Mining offers lower upfront costs and faster excavation with pillars providing inherent ground support, enhancing operational efficiency in flat-lying ore bodies. Cost analysis reveals that while Cut and Fill is more capital-intensive, its adaptability to varying ore geometries can lead to higher long-term profitability compared to the more cost-effective but less flexible Room and Pillar method.

Choosing the Right Method for Your Mine

Cut and fill mining offers precise ore recovery and enhanced ground control, making it ideal for irregular ore bodies and steeply dipping deposits. Room and pillar mining provides efficient extraction with minimal surface subsidence, suitable for flat-lying, tabular deposits with stable rock conditions. Selecting the right method depends on ore geometry, ground stability, and production goals to optimize safety and economic returns.

Related Important Terms

Engineered Backfill

Cut and fill mining utilizes engineered backfill materials such as cemented rock fill or hydraulic fill to stabilize the mined-out voids and support safe underground excavation. Room and pillar mining typically relies on natural pillars for ground support, whereas engineered backfill in cut and fill enhances ground control and allows selective ore extraction with minimized collapse risk.

Selective Extraction Sequencing

Cut and Fill Mining enables precise selective extraction sequencing by allowing targeted removal of ore in vertical slices, minimizing dilution and waste rock incorporation. In contrast, Room and Pillar Mining involves systematic excavation of horizontal rooms with pillars left intact for support, offering less flexibility in selective extraction but maintaining overall mine stability.

Cemented Paste Fill (CPF)

Cut and Fill Mining leverages Cemented Paste Fill (CPF) to backfill mined-out voids, enhancing ground stability and allowing safe extraction of high-grade ore in irregular ore bodies. In contrast, Room and Pillar Mining typically uses CPF to support pillars and maximize ore recovery while maintaining ventilation and structural integrity in horizontal ore deposits.

Pillar Recovery Optimization

Room and Pillar mining optimizes pillar recovery by carefully extracting ore while leaving strategically placed pillars to support the mine roof, thereby enhancing safety and maximizing ore retrieval. Compared to Cut and Fill mining, Room and Pillar allows for higher pillar extraction rates through controlled pillar reduction techniques and real-time monitoring of ground stability.

Underhand Cut and Fill

Underhand Cut and Fill mining involves excavating ore beneath existing pillars, allowing miners to maintain better ground control and reduce surface subsidence compared to traditional Room and Pillar methods. This technique enhances safety and ore recovery by supporting the roof with backfill, making it ideal for irregular or steeply dipping ore bodies.

Automated Drift Mapping

Automated drift mapping in Cut and Fill Mining enhances precision by continuously monitoring voids and backfill integrity, optimizing ore extraction while maintaining ground stability. In Room and Pillar Mining, this technology streamlines the mapping of interconnected tunnels, improving pillar assessment and reducing the risk of collapses through real-time spatial data integration.

Dynamic Ground Support

Cut and Fill Mining employs dynamic ground support systems such as hydraulic props and shotcrete to stabilize ore bodies in highly variable geotechnical conditions, allowing for selective extraction and enhanced safety. Room and Pillar Mining utilizes passive support methods like pillars and timber, which offer less adaptability to ground movement but maintain structural integrity in more stable rock formations.

Stope Stability Analysis

Cut and Fill Mining offers superior stope stability by allowing selective ore extraction and immediate backfilling, reducing ground deformation and collapse risks compared to Room and Pillar Mining, which relies on pillars to support the roof but often suffers from pillar failure and subsidence. Stability analysis in Cut and Fill Mining emphasizes continuous monitoring and backfill strength, while Room and Pillar requires careful pillar size optimization to maintain underground stability and prevent sudden stope failures.

Digital Geotechnical Monitoring

Cut and Fill Mining enhances safety and resource recovery through precise digital geotechnical monitoring systems that track ground stability and deformation in real time. Room and Pillar Mining benefits from digital monitoring by optimizing pillar strength assessments and minimizing collapse risks, ensuring sustainable mine ventilation and structural integrity.

Real-time Ore Dilution Control

Cut and Fill Mining offers superior real-time ore dilution control through precise excavation and backfilling, minimizing waste extraction and improving ore grade consistency. In contrast, Room and Pillar Mining often experiences higher dilution rates due to pillar recovery challenges and less controlled stoping environments.

Cut and Fill Mining vs Room and Pillar Mining Infographic

industrydif.com

industrydif.com