Tailings dams are large structures designed to store mining byproducts, primarily composed of solid particles suspended in water, which pose environmental risks if not managed properly. Paste backfill, in contrast, uses a thickened mixture of tailings and binders to fill underground mine voids, reducing surface disposal and enhancing ground support. This method improves mine safety, minimizes environmental impact, and promotes resource recovery by reusing tailings.

Table of Comparison

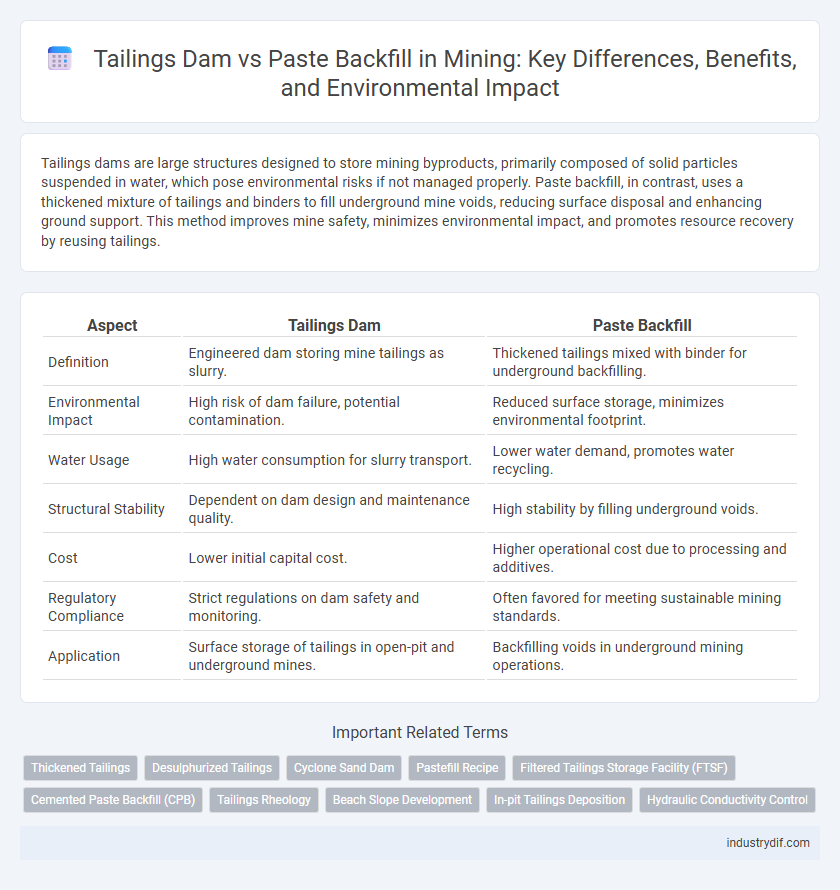

| Aspect | Tailings Dam | Paste Backfill |

|---|---|---|

| Definition | Engineered dam storing mine tailings as slurry. | Thickened tailings mixed with binder for underground backfilling. |

| Environmental Impact | High risk of dam failure, potential contamination. | Reduced surface storage, minimizes environmental footprint. |

| Water Usage | High water consumption for slurry transport. | Lower water demand, promotes water recycling. |

| Structural Stability | Dependent on dam design and maintenance quality. | High stability by filling underground voids. |

| Cost | Lower initial capital cost. | Higher operational cost due to processing and additives. |

| Regulatory Compliance | Strict regulations on dam safety and monitoring. | Often favored for meeting sustainable mining standards. |

| Application | Surface storage of tailings in open-pit and underground mines. | Backfilling voids in underground mining operations. |

Introduction to Tailings Management in Mining

Tailings dams are engineered structures designed to store byproducts of mining operations, primarily composed of slurry and fine-grained waste materials. Paste backfill involves mixing tailings with binders to create a thick, paste-like material that is used to fill underground mine voids, reducing surface disposal requirements. Effective tailings management integrates these methods to enhance environmental safety and improve resource recovery in mining operations.

What is a Tailings Dam?

A tailings dam is an engineered structure designed to store byproducts of mining operations, specifically the slurry of fine mineral residues known as tailings. It typically consists of compacted earth, rockfill, or a combination of materials, creating a reservoir to contain potentially hazardous waste and prevent environmental contamination. Tailings dams require rigorous monitoring and maintenance to ensure structural stability and reduce the risk of catastrophic failure.

What is Paste Backfill?

Paste backfill is a mining method that involves mixing mill tailings with binders such as cement or fly ash to create a thick, pumpable slurry used to fill underground mine voids. This technique enhances ground stability and reduces surface tailings storage risks compared to traditional tailings dams. Paste backfill also improves resource recovery by allowing safer extraction of adjacent ore bodies and minimizes environmental impact by limiting tailings exposure.

Key Differences: Tailings Dam vs Paste Backfill

Tailings dams store finely ground waste material from mining operations in large surface impoundments, posing risks of dam failure and environmental contamination. Paste backfill involves mixing tailings with binders to create a thick, stable slurry that is pumped underground to fill mined-out voids, reducing surface storage needs and improving ground stability. Key differences include tailings dams' surface disposal method compared to paste backfill's underground usage, with paste backfill offering enhanced safety and environmental benefits.

Environmental Impact Comparison

Tailings dams pose significant environmental risks due to potential dam failures, which can cause extensive soil and water contamination from toxic slurry releases. Paste backfill offers a safer alternative by reducing surface storage of tailings, minimizing groundwater contamination and dust generation. This method also promotes the reuse of mine waste in underground mines, lowering overall environmental footprints.

Safety Considerations and Risk Mitigation

Tailings dams pose significant safety risks due to potential structural failure, leading to catastrophic environmental damage and loss of life, whereas paste backfill offers enhanced stability by filling underground voids and reducing surface storage requirements. Effective risk mitigation for tailings dams includes rigorous geotechnical monitoring, strict regulatory compliance, and emergency preparedness protocols, while paste backfill inherently minimizes tailings volume on the surface and limits exposure to dam breach hazards. Integrating paste backfill with robust tailings management strategies can significantly improve mine site safety and environmental protection.

Economic and Lifecycle Cost Analysis

Tailings dams require substantial capital investment and ongoing maintenance costs, posing financial risks related to environmental liabilities and catastrophic failures. Paste backfill utilizes mine waste mixed with binders, reducing tailings volume and lowering disposal costs while improving underground mine stability, leading to overall cost savings in the mine lifecycle. Economic assessments often show that paste backfill minimizes long-term environmental remediation expenses and enhances resource recovery efficiency compared to conventional tailings dam management.

Operational Efficiency and Resource Recovery

Tailings dams require extensive land use and ongoing water management, increasing operational costs and risk of environmental impact, whereas paste backfill improves resource recovery by enabling underground void filling with processed tailings, reducing surface disposal needs. Paste backfill enhances operational efficiency by allowing safer mine progression and minimizing surface footprint, leading to optimized material handling and reduced community disturbance. Efficient paste backfill systems also capitalize on valuable minerals left in tailings, boosting overall recovery rates compared to conventional tailings dam storage.

Regulatory Compliance and Industry Standards

Tailings dams require stringent adherence to regulatory compliance due to their potential environmental hazards, including strict monitoring standards set by agencies like the Mine Safety and Health Administration (MSHA) and International Commission on Large Dams (ICOLD). Paste backfill offers improved regulatory alignment by reducing surface storage of tailings and stabilizing underground voids, thereby minimizing seismic and leakage risks as outlined in industry standards such as ASTM and SME guidelines. Both methods must comply with environmental impact assessments and reclamation plans, but paste backfill increasingly aligns with evolving sustainability regulations and risk management frameworks.

Future Trends in Tailings Disposal Technologies

Future trends in tailings disposal technologies emphasize the shift from conventional tailings dams to paste backfill methods due to enhanced environmental safety and reduced risk of catastrophic failures. Innovations in paste backfill utilize dewatered mine tailings mixed with binders, enabling underground backfilling that minimizes surface storage and promotes ground stability. Advanced monitoring systems and sustainable practices further support the adoption of paste backfill as a preferred solution for minimizing ecological impact in mining operations.

Related Important Terms

Thickened Tailings

Thickened tailings offer improved water recovery and reduce environmental risks compared to traditional tailings dams by increasing solids concentration before disposal. Paste backfill, utilizing thickened tailings mixed with binders, enhances underground mine stability and minimizes surface storage requirements.

Desulphurized Tailings

Desulphurized tailings used in paste backfill significantly reduce environmental risks compared to conventional tailings dams by minimizing sulfur-related acid mine drainage and enhancing structural stability. Utilizing desulphurized paste backfill improves mine safety and promotes sustainable waste management through effective recycling of mineral residues.

Cyclone Sand Dam

Cyclone Sand Dam technology offers a sustainable alternative for tailings management by enhancing the stability and permeability of paste backfill compared to traditional tailings dams. Utilizing fine sand separated via cycloning, this approach reduces environmental risks and improves the mechanical strength of backfill materials, promoting safer underground mine support and reduced surface footprint.

Pastefill Recipe

Paste backfill recipes typically combine mine tailings with binders such as cement or fly ash, optimizing tailings management by improving strength and stability while minimizing environmental impact. The paste's consistency and curing time are adjusted to meet specific underground support requirements, making paste backfill a preferred alternative to traditional tailings dams for reducing surface storage risks.

Filtered Tailings Storage Facility (FTSF)

Filtered Tailings Storage Facility (FTSF) offers enhanced stability and reduced environmental impact compared to traditional tailings dams by dewatering tailings to create a dense, stackable material that minimizes water retention and seepage risks. Unlike paste backfill, which is used underground for void filling, FTSF optimizes surface storage capacity and allows for safer, more sustainable management of mine tailings with lower need for water reclamation.

Cemented Paste Backfill (CPB)

Cemented Paste Backfill (CPB) offers enhanced ground support and reduced surface disturbance compared to traditional tailings dams by utilizing tailings mixed with cement and water to create a stable underground fill. CPB improves mine safety by minimizing tailings storage risks and promoting sustainable waste management through partial recycling of mine tailings.

Tailings Rheology

Tailings rheology critically influences the stability of tailings dams by determining the flow behavior, settling rate, and consolidation properties of the slurry, directly impacting dam safety and environmental risk. In contrast, paste backfill exhibits higher solids concentration and viscosity, offering improved rheological control that reduces water drainage and enhances structural support within underground mine voids.

Beach Slope Development

Tailings dams often exhibit variable beach slope development influenced by gravity deposition dynamics, resulting in gentler, less stable slopes. In contrast, paste backfill enables engineered control over slope gradients through hydraulic placement and consolidation, promoting steeper, more stable beach profiles that enhance dam safety and reduce environmental risks.

In-pit Tailings Deposition

In-pit tailings deposition offers a cost-effective and space-efficient method for managing tailings by storing them within mined-out pits, reducing the environmental footprint compared to traditional tailings dams. Paste backfill provides enhanced ground support and stability by mixing tailings with binders, allowing safer underground void filling but requires higher processing costs and infrastructure compared to in-pit tailings disposal.

Hydraulic Conductivity Control

Tailings dams exhibit higher hydraulic conductivity levels ranging from 10^-3 to 10^-7 m/s, posing increased risks of seepage and environmental contamination, whereas paste backfill drastically reduces permeability to between 10^-7 and 10^-9 m/s, enhancing stability and controlling fluid migration. Effective hydraulic conductivity control in paste backfill improves ground support by minimizing water flow, thereby reducing the potential for dam failure compared to conventional tailings storage methods.

Tailings dam vs Paste backfill Infographic

industrydif.com

industrydif.com