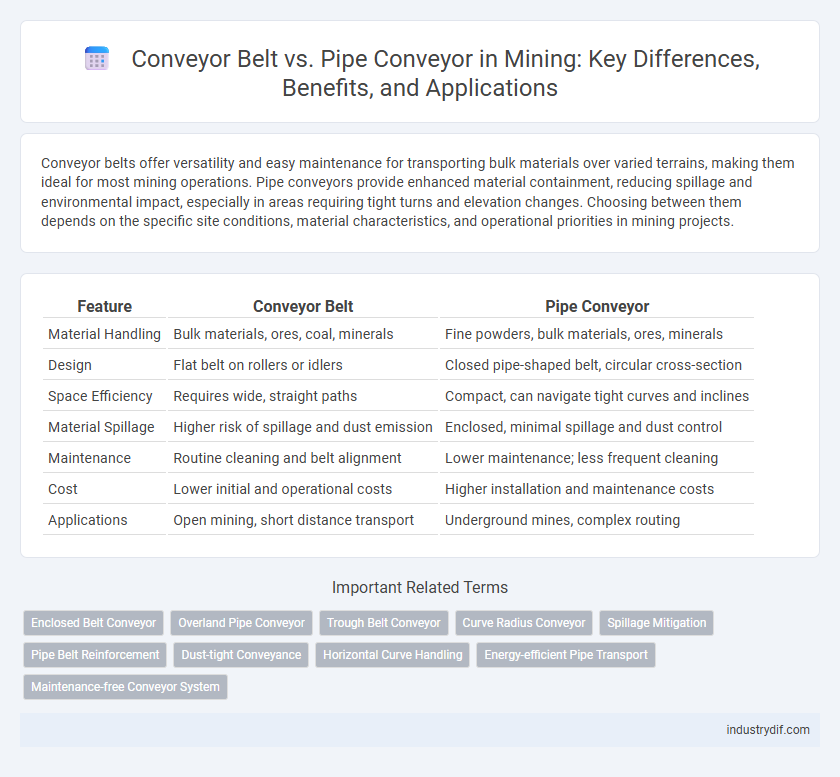

Conveyor belts offer versatility and easy maintenance for transporting bulk materials over varied terrains, making them ideal for most mining operations. Pipe conveyors provide enhanced material containment, reducing spillage and environmental impact, especially in areas requiring tight turns and elevation changes. Choosing between them depends on the specific site conditions, material characteristics, and operational priorities in mining projects.

Table of Comparison

| Feature | Conveyor Belt | Pipe Conveyor |

|---|---|---|

| Material Handling | Bulk materials, ores, coal, minerals | Fine powders, bulk materials, ores, minerals |

| Design | Flat belt on rollers or idlers | Closed pipe-shaped belt, circular cross-section |

| Space Efficiency | Requires wide, straight paths | Compact, can navigate tight curves and inclines |

| Material Spillage | Higher risk of spillage and dust emission | Enclosed, minimal spillage and dust control |

| Maintenance | Routine cleaning and belt alignment | Lower maintenance; less frequent cleaning |

| Cost | Lower initial and operational costs | Higher installation and maintenance costs |

| Applications | Open mining, short distance transport | Underground mines, complex routing |

Introduction to Conveyor Systems in Mining

Conveyor belts and pipe conveyors are essential conveyor systems in mining operations, designed for efficient bulk material transport. Conveyor belts offer versatility and high capacity for transporting minerals over long distances, while pipe conveyors provide greater flexibility in routing by enclosing materials to prevent spillage and reduce environmental impact. Selecting between these systems depends on factors like terrain complexity, material characteristics, and environmental regulations impacting mining site logistics.

Overview of Conventional Conveyor Belts

Conventional conveyor belts are widely used in mining for transporting bulk materials due to their durability and cost-effectiveness, typically consisting of a rubberized fabric belt supported by pulleys and idlers. These belts excel in horizontal and gentle incline transport but often face limitations with steep inclines and complex terrain. Maintenance involves regular inspection for belt wear, splicing damage, and roller functionality to ensure continuous and efficient material flow.

Understanding Pipe Conveyors

Pipe conveyors offer a compact and enclosed solution for transporting bulk materials, minimizing spillage and environmental impact in mining operations. Unlike traditional conveyor belts, pipe conveyors form a tubular shape that protects materials from external contamination and reduces dust emissions. This design enables efficient transport over complex terrain, including steep inclines and sharp curves, enhancing operational flexibility in mining environments.

Key Differences Between Conveyor Belts and Pipe Conveyors

Conveyor belts use a flat or troughed belt supported by rollers, suitable for transporting bulk materials over short to medium distances with ease of loading and unloading. Pipe conveyors form a tubular shape by rolling the belt edges, enabling safe material containment, reduced spillage, and the ability to handle complex routes including steep inclines and tight curves. Key differences include the pipe conveyor's enhanced environmental protection and versatility in challenging mining terrain, contrasted with the conveyor belt's simplicity and cost-effectiveness for straightforward, linear material transport.

Material Handling Efficiency Comparison

Conveyor belts offer high material handling efficiency with the ability to transport bulk materials over long distances and variable terrains, providing versatility in mining operations. Pipe conveyors outperform traditional belts by fully enclosing the material, reducing spillage and environmental contamination while maintaining a consistent flow rate. The choice between conveyor belts and pipe conveyors depends on factors such as material type, transport distance, space constraints, and environmental considerations, with pipe conveyors excelling in dusty or steep terrain conditions.

Space and Layout Considerations

Conveyor belts require wider corridors and more support structures, making them less efficient in confined mining spaces compared to pipe conveyors. Pipe conveyors offer flexible routing with minimal footprint due to their compact, enclosed design, allowing easy integration into complex layouts and around obstacles. Mining operations benefit from pipe conveyors when space constraints and irregular terrain demand efficient material transport within limited spatial parameters.

Environmental Impact and Dust Control

Conveyor belts and pipe conveyors both serve critical roles in mining material transportation, but pipe conveyors offer superior environmental benefits by fully enclosing materials, drastically reducing dust emissions and contamination risks. The enclosed design of pipe conveyors minimizes particulate matter release, effectively controlling dust pollution and improving air quality around mining sites compared to traditional open conveyor belts. This containment also limits material spillage and erosion, contributing to enhanced environmental protection and compliance with stricter mining regulations on dust control and waste management.

Maintenance and Operational Costs

Conveyor belts require frequent maintenance due to belt wear, misalignment, and idler roller replacement, leading to higher operational costs over time. Pipe conveyors, with enclosed design and fewer moving parts exposed to dust and debris, significantly reduce maintenance intervals and associated downtime. Although pipe conveyors have higher initial capital costs, their lower operational expenses and extended service life make them cost-effective for long-term mining material transport.

Safety Aspects in Mining Applications

Pipe conveyors offer enhanced safety in mining applications by providing enclosed material transport that minimizes spillage and dust emission, reducing respiratory health risks for workers. Unlike traditional conveyor belts, pipe conveyors have a compact, enclosed design that prevents exposure to moving parts, lowering the risk of accidents and injuries. Their ability to navigate complex terrain with fewer transfer points further decreases potential hazards and maintenance-related interruptions on mining sites.

Choosing the Right Conveyor System for Mining Operations

Selecting the right conveyor system for mining operations depends on factors such as material type, distance, and terrain. Conveyor belts offer flexibility and easy maintenance for transporting bulk materials over short to medium distances, while pipe conveyors excel in enclosed transport, reducing spillage and environmental impact over longer or challenging routes. Evaluating load capacity, operational efficiency, and environmental considerations ensures optimal material handling in mining projects.

Related Important Terms

Enclosed Belt Conveyor

Enclosed belt conveyors offer superior dust control and material containment compared to traditional conveyor belts, making them ideal for mining operations handling fine or abrasive materials. Their fully enclosed design reduces environmental impact and maintenance costs while enhancing safety and efficiency in bulk material transport.

Overland Pipe Conveyor

Overland pipe conveyors offer enhanced safety and environmental benefits compared to traditional conveyor belts by enclosing materials within a tubular steel structure, reducing spillage and dust emissions across extended distances. These systems are especially effective for transporting bulk materials over rugged terrain or long distances, minimizing land disturbance and maintenance costs while maximizing operational efficiency in mining operations.

Trough Belt Conveyor

Trough belt conveyors excel in high-capacity bulk material transport with their open, U-shaped design, enabling efficient handling of abrasive and heavy mining materials. Unlike pipe conveyors that enclose materials completely, trough belts offer easier maintenance and adaptability for variable terrain, making them ideal for extensive mining operations requiring reliable, cost-effective material movement.

Curve Radius Conveyor

Curve radius conveyors are essential in mining operations where space constraints demand efficient material transportation around tight bends; traditional conveyor belts struggle with maintaining consistent speed and load distribution on sharp curves. Pipe conveyors provide superior performance in these scenarios by enclosing the material within a fully enclosed, cylindrical belt that can navigate much smaller curve radii, reducing spillage and dust emissions while optimizing space utilization.

Spillage Mitigation

Pipe conveyors offer superior spillage mitigation compared to traditional flat belt conveyors through their fully enclosed design, which prevents material from falling off during transport. The tubular shape minimizes dust emissions and contamination, enhancing environmental compliance and reducing cleanup costs in mining operations.

Pipe Belt Reinforcement

Pipe conveyor systems offer superior pipe belt reinforcement through the use of high-tensile steel cables or aramid fibers embedded in the belt carcass, enhancing durability and resistance to impact and stress in harsh mining environments. This reinforcement allows the belt to maintain its tubular shape, ensuring efficient material containment and minimizing spillage compared to conventional flat conveyor belts.

Dust-tight Conveyance

Pipe conveyors provide superior dust-tight conveyance compared to traditional conveyor belts by fully enclosing the material, preventing dust emissions and reducing environmental impact in mining operations. Their tubular design minimizes spillage and contamination, enhancing workplace safety and compliance with air quality regulations.

Horizontal Curve Handling

Pipe conveyors excel in horizontal curve handling by enabling tighter bends and reducing the need for multiple transfer points, optimizing space and minimizing material spillage during mining operations. Conventional flat conveyor belts require larger radius curves and often necessitate complex support structures, increasing maintenance and operational costs.

Energy-efficient Pipe Transport

Pipe conveyors offer a more energy-efficient pipe transport solution by reducing material spillage and minimizing dust generation compared to traditional conveyor belts, resulting in lower operational costs and environmental impact. Their closed design also allows for steeper inclines and tighter curves, optimizing space and energy consumption in mining material handling.

Maintenance-free Conveyor System

A pipe conveyor offers a maintenance-free conveyor system by enclosing bulk materials within a tubular belt, preventing spillage and reducing wear on components compared to traditional conveyor belts. This design minimizes downtime and maintenance costs in mining operations, enhancing overall efficiency and reliability.

Conveyor belt vs Pipe conveyor Infographic

industrydif.com

industrydif.com