Traditional blasting in mining relies on controlled explosives to fragment rock, often resulting in significant vibration, noise, and environmental impact. Electric pulse fragmentation uses high-voltage electrical discharges to break rock with greater precision, reducing ground vibrations and minimizing damage to surrounding structures. This innovative method enhances safety, lowers operational costs, and improves overall efficiency compared to conventional blasting techniques.

Table of Comparison

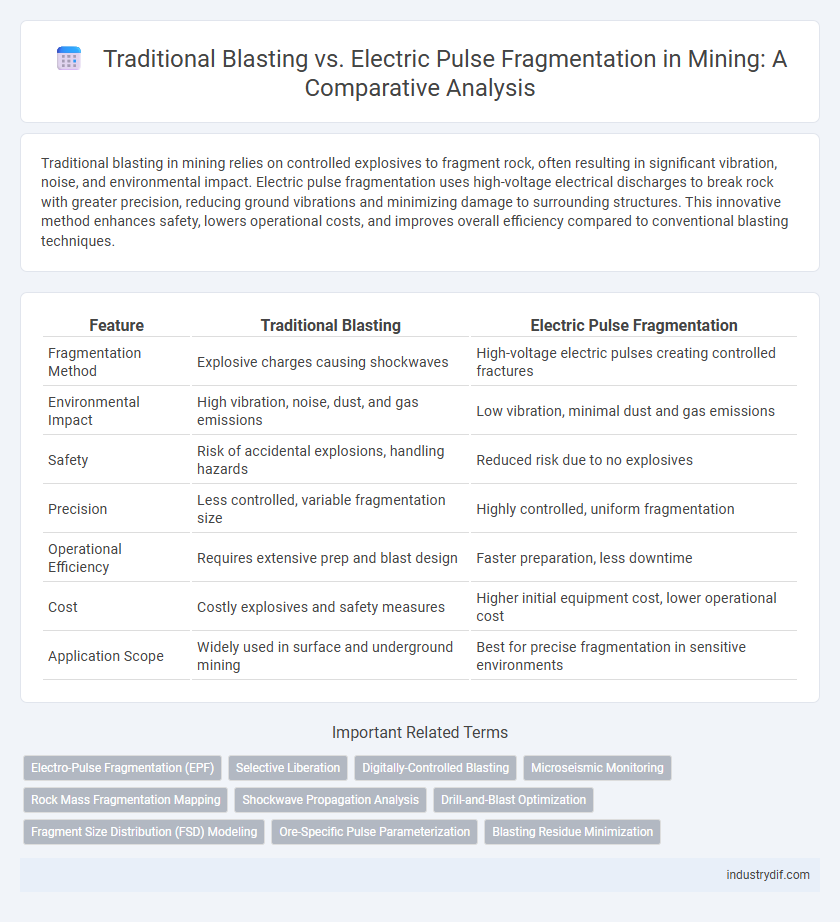

| Feature | Traditional Blasting | Electric Pulse Fragmentation |

|---|---|---|

| Fragmentation Method | Explosive charges causing shockwaves | High-voltage electric pulses creating controlled fractures |

| Environmental Impact | High vibration, noise, dust, and gas emissions | Low vibration, minimal dust and gas emissions |

| Safety | Risk of accidental explosions, handling hazards | Reduced risk due to no explosives |

| Precision | Less controlled, variable fragmentation size | Highly controlled, uniform fragmentation |

| Operational Efficiency | Requires extensive prep and blast design | Faster preparation, less downtime |

| Cost | Costly explosives and safety measures | Higher initial equipment cost, lower operational cost |

| Application Scope | Widely used in surface and underground mining | Best for precise fragmentation in sensitive environments |

Overview of Conventional Blasting Methods in Mining

Conventional blasting in mining primarily involves the use of explosives such as ANFO (ammonium nitrate fuel oil) and emulsion blends that create shock waves to fracture rock formations. These methods rely on controlled detonations in drilled boreholes to achieve fragmentation, often leading to vibration, fly rock, and environmental concerns. Despite being effective and widely adopted, traditional blasting techniques face challenges in precision, safety, and minimizing ecological impact compared to emerging technologies.

Introduction to Electric Pulse Fragmentation Technology

Electric Pulse Fragmentation (EPF) technology uses high-voltage electrical discharges to induce fractures in rock, offering a precise and environmentally friendly alternative to traditional blasting. Unlike conventional methods relying on chemical explosives, EPF minimizes vibrations, noise, and fly rock, enhancing safety and reducing environmental impact. This innovative technique enables selective fragmentation with improved efficiency and lower operational costs in mining operations.

Mechanisms of Rock Breakage: Explosives vs. Electric Pulses

Traditional blasting relies on the rapid expansion of gases from explosive detonation, generating shock waves and gas pressure that fracture the rock through compression and tension. In contrast, electric pulse fragmentation utilizes high-voltage electric discharges to induce dielectric breakdown and electrohydraulic shock in the rock, creating microcracks that propagate and cause breakage without chemical explosives. The electric pulse method offers more controlled rock fragmentation, minimizing vibration and reducing environmental impact compared to conventional explosives.

Efficiency and Fragmentation Control Comparison

Traditional blasting in mining offers robust fragmentation but often results in uneven rock size distribution and increased vibration, leading to higher operational costs and safety concerns. Electric pulse fragmentation provides superior control over rock breakage, achieving precise fragmentation with reduced environmental impact and minimal overbreak. Enhanced efficiency of electric pulse technology reduces excavation time and increases ore recovery compared to traditional explosive methods.

Environmental Impact: Emissions, Vibrations, and Noise

Traditional blasting in mining releases significant emissions, including dust and greenhouse gases, and generates intense vibrations and noise that disrupt surrounding ecosystems and communities. Electric pulse fragmentation drastically reduces airborne pollutants and greenhouse gas output by eliminating explosive chemical use, while producing minimal vibrations and noise, thereby minimizing environmental disturbance. This innovative technique supports sustainable mining practices by enhancing worker safety and preserving local biodiversity through lower environmental impact.

Safety Considerations and Operational Risks

Traditional blasting in mining involves the use of explosives that generate shockwaves and flying debris, posing significant safety risks such as accidental detonations, flyrock injuries, and ground vibrations affecting nearby structures. Electric pulse fragmentation utilizes high-voltage electric discharges to induce rock breakage with minimal vibration and no explosive materials, substantially reducing the risk of unintended explosions and improving worker safety. Operational risks are lowered with electric pulse fragmentation due to precise control over fragmentation zones and elimination of explosive handling hazards, leading to safer mining environments and reduced regulatory constraints.

Economic Analysis: Costs and Resource Utilization

Traditional blasting incurs significant expenses related to explosives, drilling, and vibration control, often resulting in higher environmental mitigation costs and equipment wear. Electric pulse fragmentation reduces operational costs by minimizing explosive use and decreasing the need for secondary breakage, leading to improved resource efficiency and lower overall maintenance expenses. Economic analysis reveals that electric pulse technology enhances cost-effectiveness by optimizing energy consumption and reducing downtime, thereby increasing productivity in mining operations.

Applications: Suitable Ore Types and Mining Conditions

Traditional blasting is widely used for hard rock mining and applications involving large-scale volume fragmentation in quarries and open-pit mines. Electric pulse fragmentation excels in precise rock breaking for sensitive environments, suitable for soft to medium-hard ores and underground operations with strict vibration control requirements. Combining electric pulse technology with conventional methods enhances ore recovery in complex geological settings where selective fragmentation is critical.

Automation and Integration with Digital Mining Systems

Electric pulse fragmentation offers superior automation capabilities through precise control systems that seamlessly integrate with advanced digital mining platforms, enhancing operational efficiency and reducing manual intervention. Traditional blasting relies on manual planning and execution, limiting its compatibility with automated digital mining workflows and real-time data analytics. Integration with digital mining systems enables electric pulse technology to optimize fragmentation parameters dynamically, improving safety and consistency across mining operations.

Future Trends and Innovations in Rock Fragmentation

Electric pulse fragmentation represents a significant future trend in rock fragmentation by offering precise, controlled fracturing with minimal environmental impact compared to traditional blasting. Innovations in electric pulse technology focus on enhancing energy efficiency, reducing vibration and noise, and improving overall safety in mining operations. These advancements promise to revolutionize rock fragmentation by increasing productivity while meeting stricter environmental regulations.

Related Important Terms

Electro-Pulse Fragmentation (EPF)

Electro-Pulse Fragmentation (EPF) utilizes high-voltage electrical discharges to create controlled fractures in rock, resulting in finer fragmentation and reduced vibrations compared to traditional blasting methods. This innovative technique enhances mining efficiency by minimizing explosive use and lowering environmental impact through precise rock breakage.

Selective Liberation

Traditional blasting relies on high-energy explosives generating shock waves that cause widespread rock fragmentation, often resulting in inefficient selective liberation with excessive fines and dilution. Electric pulse fragmentation uses controlled high-voltage pulses to induce precise rock breakage, enhancing selective liberation by minimizing damage to surrounding ore, improving ore grade recovery and reducing downstream processing costs.

Digitally-Controlled Blasting

Digitally-controlled blasting leverages electric pulse fragmentation to enhance precision and safety in mining operations by minimizing ground vibrations and fly rock compared to traditional blasting methods. This advanced technology improves fragmentation quality, reduces environmental impact, and optimizes explosive energy use, leading to increased operational efficiency and lower overall costs.

Microseismic Monitoring

Traditional blasting in mining generates high-intensity shock waves causing widespread microseismic events that complicate precise rock mass behavior analysis, while electric pulse fragmentation produces controlled stress waves resulting in lower microseismic activity and improved accuracy in microseismic monitoring for enhanced rock stability assessment. Microseismic monitoring with electric pulse fragmentation enables real-time detection of subtle fractures, optimizing blast design and reducing environmental impact compared to conventional methods.

Rock Mass Fragmentation Mapping

Traditional blasting creates irregular fragmentation patterns in rock masses, often resulting in uneven particle sizes and increased need for secondary breakage. Electric pulse fragmentation offers precise rock mass fragmentation mapping by generating controlled fractures, enhancing efficiency and reducing environmental impact in mining operations.

Shockwave Propagation Analysis

Traditional blasting relies on chemical explosives generating shockwaves that propagate through rock mass causing fragmentation, whereas electric pulse fragmentation uses high-voltage electric discharges inducing stress waves with more controlled shockwave propagation patterns. Shockwave propagation analysis reveals that electric pulse fragmentation produces less seismic damage and improved energy efficiency by creating localized fractures without extensive shockwave attenuation typical in conventional blasting.

Drill-and-Blast Optimization

Electric pulse fragmentation enhances drill-and-blast optimization by generating precise rock breakage with reduced vibration and fragmentation variability, leading to lower explosive consumption and improved fragmentation uniformity compared to traditional blasting methods. This technology enables better control over blast outcomes, improving overall operational efficiency and minimizing environmental impact in mining projects.

Fragment Size Distribution (FSD) Modeling

Electric pulse fragmentation offers a more precise control over Fragment Size Distribution (FSD) compared to traditional blasting, enabling finer and more uniform rock fragmentation with reduced overbreak and waste material. Modeling FSD in electric pulse fragmentation incorporates factors such as pulse energy, rock properties, and electrode configuration to optimize fragment size for improved downstream processing efficiency.

Ore-Specific Pulse Parameterization

Traditional blasting relies on generic explosive charges, often resulting in uneven fragmentation and excessive vibration, while electric pulse fragmentation utilizes ore-specific pulse parameterization to precisely control energy delivery, enhancing breakage efficiency and reducing environmental impact. Tailoring pulse parameters to ore characteristics improves fragmentation uniformity and optimizes resource recovery, making electric pulse technology a superior alternative in modern mining operations.

Blasting Residue Minimization

Electric pulse fragmentation significantly reduces blasting residue compared to traditional blasting by generating controlled fractures without excessive vibration or flyrock, enhancing ore recovery and minimizing environmental impact. This precise method decreases the volume of unbroken rock and reduces secondary blasting requirements, leading to improved operational efficiency and lower waste management costs.

Traditional blasting vs Electric pulse fragmentation Infographic

industrydif.com

industrydif.com