Heavy machinery has long been the backbone of mining operations, providing robust power and versatility for a wide range of tasks. Autonomous Haulage Systems (AHS) enhance efficiency by reducing human error and operational costs while enabling continuous, precise material transport in mining environments. The integration of AHS results in improved safety and productivity compared to traditional heavy machinery, transforming the landscape of modern mining practices.

Table of Comparison

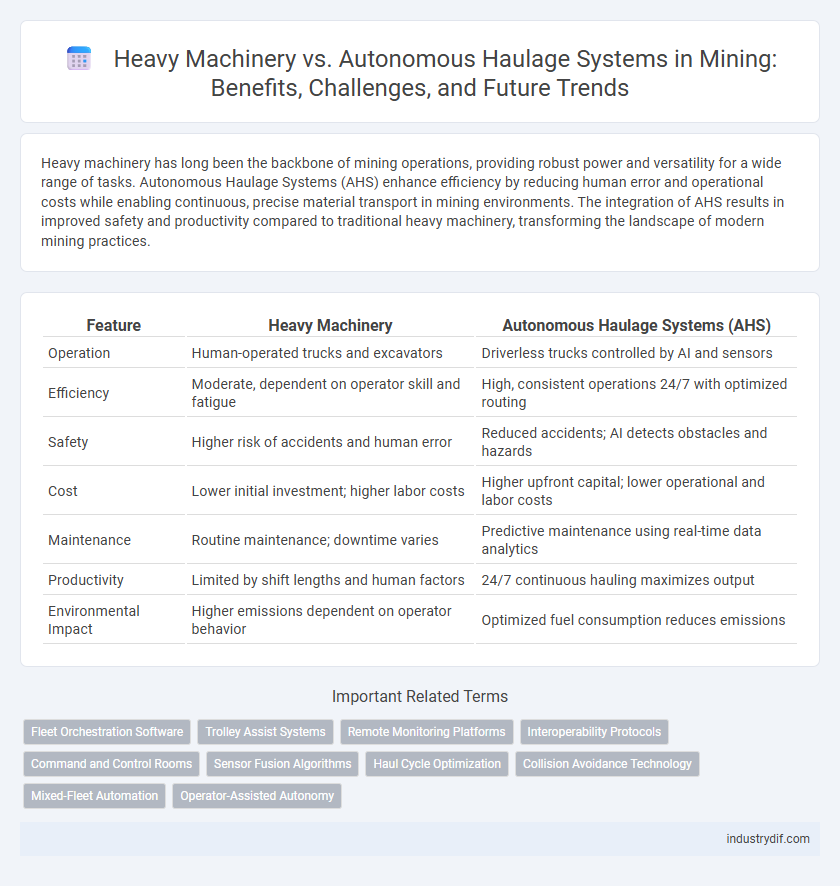

| Feature | Heavy Machinery | Autonomous Haulage Systems (AHS) |

|---|---|---|

| Operation | Human-operated trucks and excavators | Driverless trucks controlled by AI and sensors |

| Efficiency | Moderate, dependent on operator skill and fatigue | High, consistent operations 24/7 with optimized routing |

| Safety | Higher risk of accidents and human error | Reduced accidents; AI detects obstacles and hazards |

| Cost | Lower initial investment; higher labor costs | Higher upfront capital; lower operational and labor costs |

| Maintenance | Routine maintenance; downtime varies | Predictive maintenance using real-time data analytics |

| Productivity | Limited by shift lengths and human factors | 24/7 continuous hauling maximizes output |

| Environmental Impact | Higher emissions dependent on operator behavior | Optimized fuel consumption reduces emissions |

Introduction to Mining Equipment Evolution

The evolution of mining equipment has rapidly shifted from traditional heavy machinery to advanced autonomous haulage systems, enhancing operational efficiency and safety. Autonomous haulage systems leverage artificial intelligence and GPS technology to optimize fleet management and reduce human error in mining operations. This transition marks a significant technological milestone in the industry's pursuit of cost reduction and productivity improvement.

Defining Heavy Machinery in Traditional Mining

Heavy machinery in traditional mining encompasses large-scale equipment such as excavators, loaders, and haul trucks operated by human workers to extract and transport minerals. These machines are designed for durability, high capacity, and versatility in rugged mining environments, relying heavily on manual control and operator expertise. The integration of GPS and telematics has begun enhancing efficiency, but operational limitations and safety risks remain inherent to human-driven machinery.

Overview of Autonomous Haulage Systems (AHS)

Autonomous Haulage Systems (AHS) revolutionize mining operations by employing driverless trucks equipped with GPS, sensors, and advanced AI for precise navigation and load management. These systems enhance operational efficiency, reduce human error, and improve safety by enabling continuous, remote-controlled hauling in various mining environments. Integration of AHS with real-time data analytics facilitates optimized fleet management, minimizing downtime and fuel consumption compared to traditional heavy machinery.

Operational Efficiency: Manual vs. Automated Fleets

Heavy machinery in mining relies on manual operation, which often leads to variability in productivity due to human factors like fatigue and skill level. Autonomous Haulage Systems (AHS) enable continuous operation with precise navigation, reducing downtime and optimizing haul cycle times. Automated fleets integrate real-time data analytics and predictive maintenance, significantly enhancing operational efficiency compared to traditional manual fleets.

Safety Standards: Reducing Risks with Automation

Autonomous Haulage Systems (AHS) significantly enhance safety standards in mining by minimizing human error and exposure to hazardous conditions, reducing incident rates compared to traditional heavy machinery operated manually. Advanced sensors, real-time monitoring, and automated controls enable AHS to detect obstacles and avoid collisions, fostering a safer work environment. The integration of automation in haulage processes aligns with stringent safety regulations, contributing to efficient risk management and improved operational safety outcomes.

Cost Implications: CAPEX and OPEX Comparisons

Heavy machinery in mining requires significant upfront capital expenditure (CAPEX) for equipment purchase and installation, alongside high operational expenditure (OPEX) due to fuel, maintenance, and labor costs. Autonomous haulage systems (AHS) involve higher initial CAPEX driven by advanced technology integration, such as sensors, AI software, and communication infrastructure, but deliver substantial OPEX savings through reduced labor expenses, lower fuel consumption, and minimized downtime. Cost-benefit analyses indicate that AHS can achieve a lower total cost of ownership over the equipment lifecycle, boosting efficiency and profitability in large-scale mining operations.

Workforce Shifts: Skills for Heavy Machinery vs. AHS

Heavy machinery operation in mining demands skilled operators proficient in manual control, mechanical troubleshooting, and safety protocols, emphasizing hands-on experience. Autonomous Haulage Systems (AHS) require a workforce with expertise in robotics, software management, and data analysis to monitor and optimize autonomous vehicle fleets. Transitioning to AHS shifts workforce needs towards advanced technical skills in automation, reducing reliance on traditional heavy machinery operators while increasing roles in system maintenance and cybersecurity.

Environmental Impact: Fuel, Emissions, and Sustainability

Autonomous Haulage Systems (AHS) significantly reduce fuel consumption by optimizing route efficiency and minimizing idle time compared to traditional heavy machinery, leading to lower greenhouse gas emissions. The use of electric or hybrid autonomous vehicles further enhances sustainability by decreasing reliance on diesel fuel and reducing particulate matter emissions. These advancements in automation contribute to improved environmental performance and support mining operations' goals for carbon footprint reduction and regulatory compliance.

Integration Challenges and Infrastructure Needs

Integration of Autonomous Haulage Systems (AHS) with existing heavy machinery in mining requires significant upgrades to communication networks and control infrastructure to support real-time data exchange and remote operation. Heavy machinery must be retrofitted with sensors and GPS technology to interface seamlessly with autonomous systems, while existing haul roads and loading sites need modifications to accommodate automated vehicle navigation. Infrastructure investments also include enhanced cybersecurity measures and centralized control hubs to ensure operational safety and reliability during the transition.

Future Trends in Mining Equipment Automation

Future trends in mining equipment automation emphasize the shift from traditional heavy machinery to autonomous haulage systems (AHS) that enhance operational efficiency and safety. Autonomous haulage systems employ advanced sensors, AI, and GPS technology to perform precise transport tasks, reducing human error and operational costs. Continued innovation in machine learning and connectivity is driving the widespread adoption of AHS, promoting real-time data integration and predictive maintenance in mining operations.

Related Important Terms

Fleet Orchestration Software

Fleet orchestration software streamlines mining operations by optimizing heavy machinery deployment and coordinating autonomous haulage systems for improved productivity and cost efficiency. Integrating real-time data analytics, the software enhances fleet utilization, reduces downtime, and supports seamless interaction between manned and autonomous vehicles in complex mining environments.

Trolley Assist Systems

Trolley assist systems in mining combine heavy machinery with autonomous haulage systems to enhance energy efficiency and reduce emissions by using electrified overhead lines for powered trucks on steep hauls. These systems optimize fuel consumption, increase hauling speeds, and extend vehicle lifespan compared to traditional diesel-powered haul trucks operating independently.

Remote Monitoring Platforms

Remote monitoring platforms enhance operational efficiency by providing real-time data analytics and predictive maintenance alerts for both heavy machinery and autonomous haulage systems. These platforms enable centralized control, reducing downtime and improving safety through continuous tracking of equipment health and performance metrics.

Interoperability Protocols

Interoperability protocols in mining enable seamless communication and data exchange between heavy machinery and autonomous haulage systems (AHS), enhancing operational efficiency and safety. Standardized protocols such as CAN bus, OPC UA, and ISO 15118 facilitate integration, real-time monitoring, and coordinated fleet management across diverse equipment brands and technologies.

Command and Control Rooms

Command and control rooms in mining operations integrating Autonomous Haulage Systems (AHS) leverage real-time data analytics and centralized monitoring to optimize fleet efficiency, reducing human error compared to traditional heavy machinery operations. Advanced visualization tools and predictive maintenance algorithms within these control centers enhance decision-making, ensuring continuous operation and minimizing downtime.

Sensor Fusion Algorithms

Sensor fusion algorithms integrate data from LiDAR, radar, and GPS in autonomous haulage systems to enhance precision and safety in mining operations, outperforming traditional heavy machinery reliant on manual control. These algorithms enable real-time environment mapping and obstacle detection, significantly reducing operational risks and optimizing haulage efficiency.

Haul Cycle Optimization

Heavy machinery in mining relies on operator skill and real-time adjustments, whereas Autonomous Haulage Systems (AHS) use advanced algorithms and sensors to optimize haul cycles by reducing idle times, improving route efficiency, and enabling precise load management. Implementing AHS enhances productivity through continuous data analysis and adaptive decision-making, leading to shorter cycle times and increased overall mine throughput.

Collision Avoidance Technology

Heavy machinery in mining relies on advanced sensors and radar systems for collision avoidance, ensuring operator control mitigates risks effectively. In contrast, autonomous haulage systems leverage AI-powered LiDAR and machine learning algorithms to detect obstacles and execute real-time evasive maneuvers, significantly reducing accident rates and enhancing site safety.

Mixed-Fleet Automation

Mixed-fleet automation in mining integrates heavy machinery with autonomous haulage systems to optimize operational efficiency and reduce downtime. Combining manual and autonomous equipment enables seamless coordination, enhances safety, and maximizes asset utilization in complex mining environments.

Operator-Assisted Autonomy

Operator-assisted autonomy in mining combines human oversight with automated functions to enhance safety and efficiency in heavy machinery operations. This hybrid approach reduces operator fatigue while maintaining situational awareness, allowing seamless control alongside autonomous haulage systems for improved productivity and minimized downtime.

Heavy Machinery vs Autonomous Haulage Systems Infographic

industrydif.com

industrydif.com