Heap leaching and vat leaching are both hydrometallurgical processes used in mining to extract valuable metals from ore, but heap leaching involves stacking crushed ore in large piles where a leaching solution percolates through, while vat leaching uses large tanks to immerse finely ground ore in a leaching solution. Heap leaching is generally preferred for low-grade ores and large-scale operations due to its lower cost and simpler infrastructure, whereas vat leaching offers higher recovery rates and better control over leaching conditions, making it suitable for higher-grade ores. The choice between heap and vat leaching depends on factors such as ore type, grade, operational scale, and economic considerations.

Table of Comparison

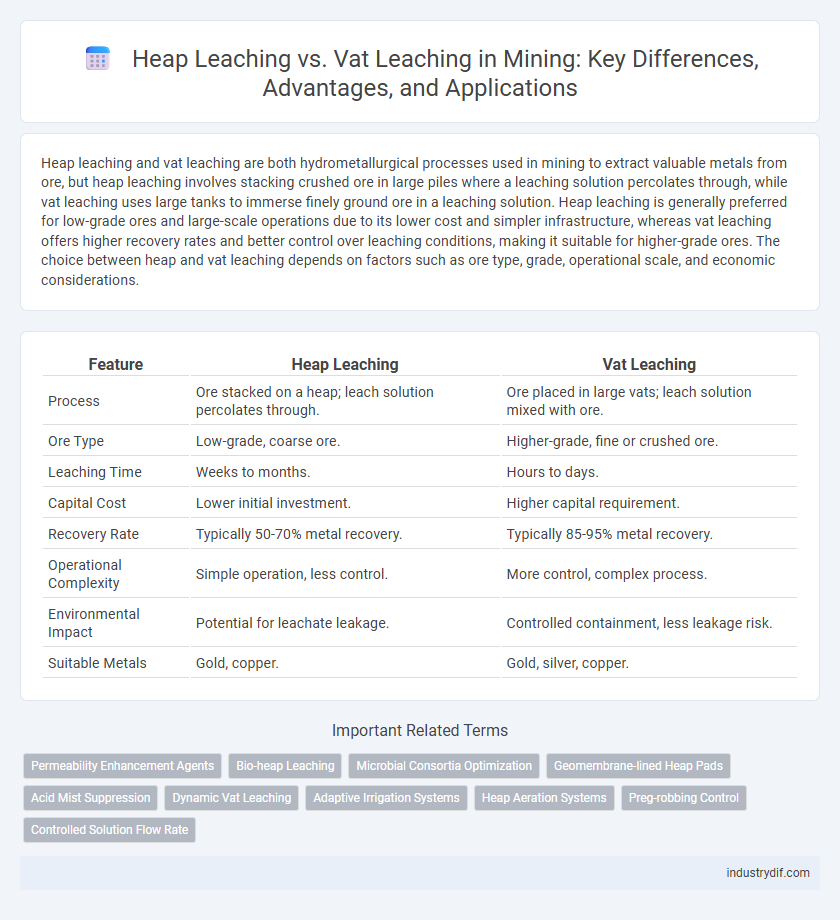

| Feature | Heap Leaching | Vat Leaching |

|---|---|---|

| Process | Ore stacked on a heap; leach solution percolates through. | Ore placed in large vats; leach solution mixed with ore. |

| Ore Type | Low-grade, coarse ore. | Higher-grade, fine or crushed ore. |

| Leaching Time | Weeks to months. | Hours to days. |

| Capital Cost | Lower initial investment. | Higher capital requirement. |

| Recovery Rate | Typically 50-70% metal recovery. | Typically 85-95% metal recovery. |

| Operational Complexity | Simple operation, less control. | More control, complex process. |

| Environmental Impact | Potential for leachate leakage. | Controlled containment, less leakage risk. |

| Suitable Metals | Gold, copper. | Gold, silver, copper. |

Overview of Heap Leaching and Vat Leaching

Heap leaching involves stacking ore in large piles and applying a leaching solution to extract target metals, making it ideal for low-grade ores due to its cost-effectiveness and scalability. Vat leaching processes crushed ore in large tanks, allowing for controlled conditions and higher recovery rates, typically used for high-grade ores. Both methods utilize chemical solutions like cyanide or sulfuric acid, but heap leaching offers lower operational costs while vat leaching provides faster metal recovery and better environmental containment.

Key Process Differences Between Heap and Vat Leaching

Heap leaching involves stacking crushed ore on a liner and applying leaching solutions to percolate through the heap for metal recovery, whereas vat leaching processes finely ground ore in large tanks with controlled agitation and temperature. Heap leaching is typically used for low-grade ores due to its cost-effectiveness and slower extraction rates, while vat leaching offers faster metal recovery and higher yield for higher-grade ores through enhanced contact between ore and lixiviant. The differing operational scales and ore preparation methods define their suitability across various mining projects focused on gold, copper, and other metal extractions.

Suitable Ore Types for Heap and Vat Leaching

Heap leaching is suitable for low-grade ores with high permeability, such as oxide copper ores and gold-bearing sulfides, enabling cost-effective metal extraction from large volumes of ore. Vat leaching is ideal for high-grade ores with fine particle sizes and low permeability, often used for complex sulfide ores or ores requiring precise control over leaching conditions. Selection between heap and vat leaching depends on ore mineralogy, particle size distribution, and metal recovery efficiency.

Equipment and Infrastructure Requirements

Heap leaching requires large, permeable pads constructed with liners and drainage systems to facilitate the percolation of leaching solutions, while vat leaching involves robust, sealed tanks designed to handle controlled chemical reactions in contained environments. Equipment for heap leaching includes large-scale irrigation systems and solvent recovery units, whereas vat leaching demands agitators, pumps, and specialized tanks capable of withstanding corrosive chemicals. Infrastructure costs for heap leaching are generally lower due to its simpler setup, but vat leaching provides greater process control and higher recovery rates through intensive mechanical and chemical management.

Chemical Agents Used in Each Leaching Method

Heap leaching primarily utilizes dilute cyanide solutions to extract gold from low-grade ores, relying on chemical agents like sodium cyanide and lime to maintain pH and prevent hydrogen cyanide formation. Vat leaching employs stronger reagents, often higher concentrations of cyanide or sulfuric acid, applied directly to finely crushed ore in controlled tanks to accelerate metal recovery. The choice of chemical agents depends on ore type, environmental considerations, and operational scale, with heap leaching favoring less aggressive chemicals for extended processing times.

Environmental Impact Comparison

Heap leaching generates more potential environmental risks due to large sulfuric acid volumes that can lead to groundwater contamination and surface water runoff, demanding extensive liner systems and monitoring protocols. Vat leaching, with its controlled batch processing in enclosed containers, significantly reduces the risk of leachate leakage and limits airborne emissions, lowering the overall environmental footprint. Waste management is also more manageable in vat leaching, minimizing soil and water pollution compared to the open heaps used in heap leaching.

Cost Analysis: Heap Leaching vs Vat Leaching

Heap leaching typically offers lower operational and capital costs due to its simpler infrastructure and ability to process low-grade ores on a large scale, resulting in reduced energy consumption and labor requirements. Vat leaching involves higher upfront investment in equipment and maintenance, along with increased energy costs for agitation and temperature control, but it can achieve higher recovery rates for certain ores. Evaluating ore grade, recovery efficiency, and production scale is essential to determine the most cost-effective leaching method for mining projects.

Recovery Rates and Efficiency

Heap leaching typically offers lower recovery rates ranging from 50% to 70%, making it suitable for low-grade ores due to its cost-effectiveness and scalability. Vat leaching achieves higher recovery rates, often exceeding 90%, because of controlled conditions that enhance reagent contact and metal dissolution. Efficiency in vat leaching is greater for ores requiring precise treatment, while heap leaching is favored for large volumes where economic feasibility outweighs maximum metal recovery.

Operational Challenges and Limitations

Heap leaching encounters operational challenges such as slow metal recovery rates and susceptibility to uneven solution distribution, which can lead to inefficient metal extraction. Vat leaching faces limitations including higher capital costs and complex agitation requirements to maintain uniform chemical reactions, impacting process scalability. Both methods struggle with managing reagent consumption and controlling environmental risks like cyanide leachate, necessitating stringent monitoring and containment.

Industry Applications and Case Studies

Heap leaching is widely applied in the mining industry for processing low-grade ores, especially in large-scale copper and gold operations, due to its cost-effectiveness and scalability, as seen in projects like the Escondida copper mine in Chile. Vat leaching, preferred for high-grade ore and smaller batches, offers more controlled conditions and higher recovery rates, exemplified by gold processing at the Homestake Mine in South Dakota. Industry case studies demonstrate that heap leaching suits bulk, low-cost extraction while vat leaching is optimal for precision and maximizing metal recovery in complex or high-value ores.

Related Important Terms

Permeability Enhancement Agents

Heap leaching employs permeability enhancement agents such as nutrient solutions and soil amendments to increase porosity and solution flow through large ore piles, improving metal recovery efficiency. Vat leaching typically relies on mechanical agitation and controlled conditions, with limited use of permeability enhancers due to the confined vessel environment.

Bio-heap Leaching

Bio-heap leaching enhances metal recovery by leveraging microorganisms to accelerate the breakdown of ore in a heap, offering a cost-effective and scalable alternative to vat leaching, which requires controlled reactor conditions and higher operational costs. Compared to vat leaching, bio-heap leaching improves environmental sustainability through lower energy consumption and minimal chemical usage, making it particularly effective for low-grade sulfide ores.

Microbial Consortia Optimization

Heap leaching benefits from microbial consortia optimization by enhancing the oxidation of sulfide minerals through tailored microbial communities, improving metal recovery rates and reducing processing time. Vat leaching's controlled environment allows for precise manipulation of microbial populations, facilitating the optimization of biooxidation kinetics and maximizing extraction efficiency in precious metal processing.

Geomembrane-lined Heap Pads

Heap leaching utilizes geomembrane-lined heap pads to facilitate efficient percolation of leaching solutions over large ore volumes, optimizing metal recovery and minimizing environmental contamination. In contrast, vat leaching relies on smaller, contained reactors without the expansive use of geomembrane liners, resulting in different operational scales and containment challenges.

Acid Mist Suppression

Heap leaching produces more acid mist due to the large exposed surface area and prolonged acid application, requiring advanced suppression techniques such as mist collectors and neutralizing sprays. Vat leaching confines the leaching solution within sealed tanks, significantly reducing acid mist emissions and enabling more efficient acid mist control through closed-system ventilation and scrubbers.

Dynamic Vat Leaching

Dynamic Vat Leaching enhances metal recovery efficiency by continuously agitating ore within controlled vats, increasing the contact between the leaching solution and mineral particles compared to static heap leaching. This method reduces leaching time and improves dissolution rates of valuable metals such as gold and copper, optimizing production in mining operations.

Adaptive Irrigation Systems

Heap leaching utilizes adaptive irrigation systems to optimize the percolation of leach solutions over large ore heaps, enhancing metal recovery efficiency by precisely controlling fluid distribution and minimizing solution runoff. In contrast, vat leaching employs static tanks where adaptive irrigation technology is less applicable, making heap leaching more suitable for integrating advanced irrigation controls in large-scale mining operations.

Heap Aeration Systems

Heap aeration systems enhance the efficiency of heap leaching by promoting oxygen flow, accelerating the oxidation of sulfide minerals and boosting gold recovery rates compared to vat leaching, which relies on controlled tanks and slower chemical reactions. Optimized aeration in heap leaching reduces processing time and operational costs, making it a preferred method for large-scale, low-grade ore treatment in mining operations.

Preg-robbing Control

Heap leaching involves stacking ore on a pad for percolation of leaching solution, making it more susceptible to preg-robbing due to exposure and oxidation, whereas vat leaching processes ore in controlled tanks, offering better containment and easier implementation of preg-robbing control measures. Preg-robbing control in vat leaching typically includes adding carbonaceous matter neutralizers and adjusting pH to prevent loss of precious metals, whereas heap leaching often requires pre-treatment or bio-oxidation to mitigate preg-robbing effects.

Controlled Solution Flow Rate

Heap leaching employs a slower, gravity-driven solution flow rate through large ore heaps, enabling extended contact time for metal extraction, whereas vat leaching utilizes a controlled, pumped solution flow rate within closed tanks for uniform diffusion and accelerated metal recovery. Precision in regulating solution flow rate during vat leaching optimizes reagent use and metal yield compared to the less controlled percolation in heap leaching.

Heap leaching vs Vat leaching Infographic

industrydif.com

industrydif.com