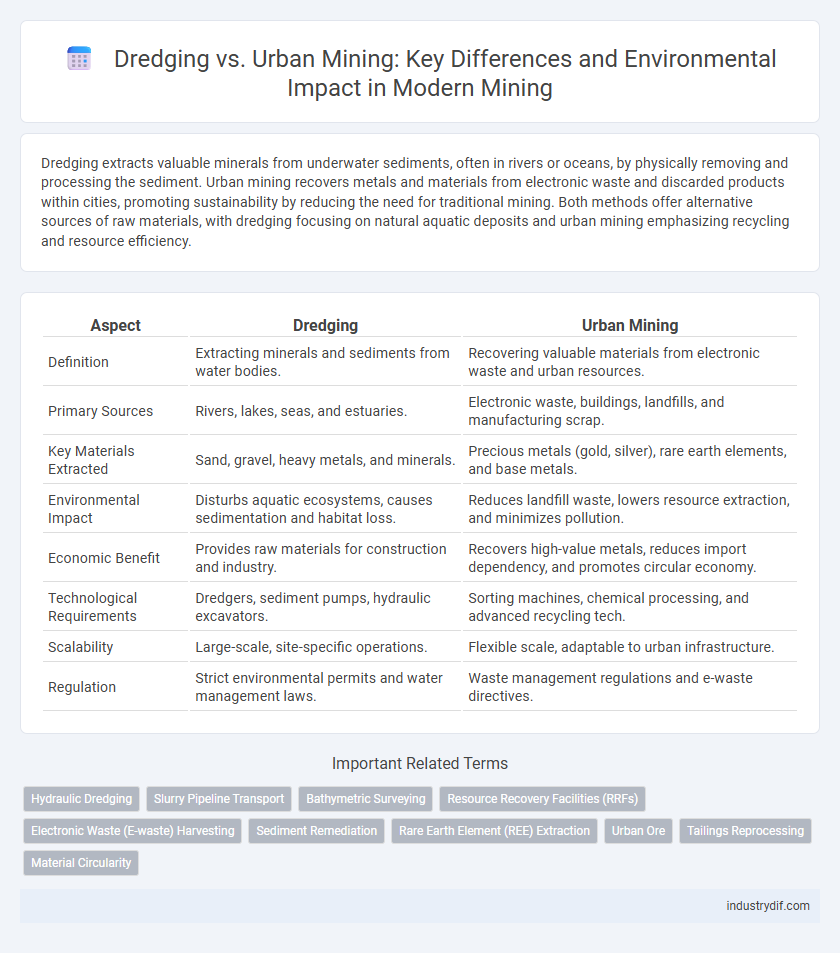

Dredging extracts valuable minerals from underwater sediments, often in rivers or oceans, by physically removing and processing the sediment. Urban mining recovers metals and materials from electronic waste and discarded products within cities, promoting sustainability by reducing the need for traditional mining. Both methods offer alternative sources of raw materials, with dredging focusing on natural aquatic deposits and urban mining emphasizing recycling and resource efficiency.

Table of Comparison

| Aspect | Dredging | Urban Mining |

|---|---|---|

| Definition | Extracting minerals and sediments from water bodies. | Recovering valuable materials from electronic waste and urban resources. |

| Primary Sources | Rivers, lakes, seas, and estuaries. | Electronic waste, buildings, landfills, and manufacturing scrap. |

| Key Materials Extracted | Sand, gravel, heavy metals, and minerals. | Precious metals (gold, silver), rare earth elements, and base metals. |

| Environmental Impact | Disturbs aquatic ecosystems, causes sedimentation and habitat loss. | Reduces landfill waste, lowers resource extraction, and minimizes pollution. |

| Economic Benefit | Provides raw materials for construction and industry. | Recovers high-value metals, reduces import dependency, and promotes circular economy. |

| Technological Requirements | Dredgers, sediment pumps, hydraulic excavators. | Sorting machines, chemical processing, and advanced recycling tech. |

| Scalability | Large-scale, site-specific operations. | Flexible scale, adaptable to urban infrastructure. |

| Regulation | Strict environmental permits and water management laws. | Waste management regulations and e-waste directives. |

Introduction to Dredging and Urban Mining

Dredging involves the excavation of underwater sediments to extract valuable minerals, metals, and aggregates, making it essential for maintaining navigable waterways and recovering resources from riverbeds or seabeds. Urban mining refers to the process of reclaiming raw materials from electronic waste, discarded vehicles, and construction debris within urban environments, reducing dependence on traditional mining by recycling metals like gold, copper, and rare earth elements. Both dredging and urban mining play crucial roles in resource recovery, addressing environmental concerns while contributing to sustainable material supply chains.

Defining Dredging in the Mining Industry

Dredging in the mining industry involves the excavation and removal of underwater sediments and minerals using specialized equipment such as dredgers and suction pumps. This process is primarily used to extract valuable materials like sand, gravel, and precious metals from riverbeds, lakes, and ocean floors. Unlike urban mining, which recovers metals from electronic waste and discarded materials, dredging targets natural deposits in aquatic environments for resource extraction.

Understanding Urban Mining: Key Concepts

Urban mining involves recovering valuable metals and materials from electronic waste, old buildings, and industrial by-products, reducing the need for traditional dredging methods that extract resources from natural water bodies. This sustainable approach capitalizes on the high concentration of precious metals in urban waste streams, promoting recycling and resource efficiency. Understanding urban mining is crucial for developing circular economies and minimizing environmental impacts compared to conventional dredging practices.

Comparing Technological Approaches

Dredging relies on traditional excavation and sediment removal technologies, employing heavy machinery such as suction pumps and cutter heads to extract materials from underwater environments. Urban mining utilizes advanced recycling technologies, including automated sorting systems, hydrometallurgical and pyrometallurgical processes to recover valuable metals from electronic waste and industrial byproducts. Both approaches focus on resource recovery, but dredging emphasizes large-scale sediment extraction while urban mining targets high-efficiency material reclamation from complex waste streams.

Resource Recovery: Waterways vs. Urban Environments

Dredging recovers sediment and valuable materials such as sand, gravel, and minerals from waterways, helping to maintain navigable channels and restore aquatic ecosystems. Urban mining focuses on extracting precious metals like gold, silver, and rare earth elements from electronic waste, batteries, and construction materials in densely populated areas. Both methods contribute significantly to resource recovery, with dredging addressing natural sediment accumulation and urban mining tackling the growing demand for sustainable circular economy solutions.

Environmental Impact Assessment

Dredging often causes significant aquatic ecosystem disruption, leading to habitat destruction, increased turbidity, and sediment displacement that affects water quality and marine life. Urban mining recovers valuable metals and rare earth elements from electronic waste with minimal land disturbance, reducing the need for traditional mining and lowering greenhouse gas emissions. Environmental Impact Assessment for dredging emphasizes water pollution control and biodiversity conservation, whereas urban mining assesses waste management efficiency and toxic substance containment.

Economic Viability and Cost Analysis

Dredging involves extracting minerals or sediments from water bodies using heavy machinery, often incurring high operational and environmental remediation costs. Urban mining recovers valuable metals from electronic waste and discarded materials, offering lower extraction expenses and reduced environmental impact, enhancing overall economic viability. Cost analysis reveals urban mining's potential for higher profit margins due to resource efficiency, minimized raw material reliance, and compliance with stricter environmental regulations.

Regulatory Frameworks and Compliance

Dredging operations in mining are governed by stringent water use and environmental protection regulations, often requiring permits to manage sediment displacement and aquatic ecosystem impacts. Urban mining, involving the recovery of valuable metals from electronic waste, falls under waste management and hazardous materials compliance frameworks that emphasize safe handling, recycling standards, and contamination prevention. Both mining methods must align with international protocols, such as the Basel Convention for hazardous waste, ensuring regulatory adherence and sustainable resource recovery practices.

Innovations and Future Trends

Dredging innovations emphasize advanced automation and eco-friendly techniques to enhance sediment extraction efficiency and reduce environmental impact in marine mining. Urban mining leverages cutting-edge technologies such as AI-driven material recovery and robotics to extract valuable metals from electronic waste, promoting circular economy principles. Future trends indicate a convergence of these methods with smart sensors and sustainable practices, driving resource optimization and reducing reliance on traditional mining.

Challenges and Opportunities in Modern Mining

Dredging faces challenges such as environmental disruption, high energy consumption, and sediment disposal, while offering opportunities in accessing underwater mineral resources and reclaiming land. Urban mining presents difficulties related to complex material separation, contamination, and regulatory hurdles, but enables sustainable recovery of precious metals from electronic waste and reduces reliance on traditional mining. Both methods drive innovation in resource extraction, emphasizing environmental sustainability and circular economy principles in modern mining.

Related Important Terms

Hydraulic Dredging

Hydraulic dredging, a technique commonly used in traditional dredging, involves the excavation of underwater materials through powerful water jets and suction pipelines, efficiently removing sediments and minerals from aquatic environments. In contrast, urban mining recovers valuable metals and materials from electronic waste and urban residues, promoting resource recycling without the environmental disruption associated with hydraulic dredging.

Slurry Pipeline Transport

Slurry pipeline transport in dredging efficiently moves excavated sediments and mineral-laden slurry over long distances, reducing environmental impact and minimizing the need for truck transport. Urban mining's slurry pipelines streamline the recovery of valuable metals from electronic waste by safely transporting fine particulates and slurry mixtures for processing in recycling facilities.

Bathymetric Surveying

Bathymetric surveying plays a critical role in dredging operations by mapping underwater topography to optimize sediment removal and ensure navigational safety. In contrast, urban mining leverages advanced spatial data, often integrating bathymetric information from water bodies in metropolitan areas, to recover valuable materials efficiently from submerged infrastructure.

Resource Recovery Facilities (RRFs)

Resource Recovery Facilities (RRFs) in urban mining efficiently extract valuable metals from electronic waste, reducing the need for traditional dredging methods that disturb aquatic ecosystems and sediments. Urban mining via RRFs offers sustainable resource recovery by minimizing environmental impact and maximizing the reclamation of rare earth elements and precious metals from discarded electronics.

Electronic Waste (E-waste) Harvesting

Dredging recovers valuable minerals by extracting sediments from water bodies, but urban mining targets electronic waste (e-waste) to efficiently harvest precious metals like gold, silver, and rare earth elements embedded in discarded devices. Urban mining reduces environmental impact by diverting e-waste from landfills and promoting a circular economy through sustainable resource recovery.

Sediment Remediation

Dredging involves the physical removal of contaminated sediments from water bodies to restore aquatic environments, often leading to significant disruption and disposal challenges. Urban mining focuses on extracting valuable metals from electronic waste and urban materials, offering a sustainable alternative that minimizes sediment disturbance while addressing contamination through resource recovery and sediment remediation.

Rare Earth Element (REE) Extraction

Dredging for Rare Earth Element (REE) extraction involves sediment removal from riverbeds or seabeds, often disrupting aquatic ecosystems and yielding lower concentrations of REEs compared to urban mining. Urban mining recovers REEs from electronic waste and industrial scrap, offering a sustainable, efficient supply with reduced environmental impact and higher material purity.

Urban Ore

Urban mining recovers valuable metals such as gold, copper, and rare earth elements from electronic waste and discarded consumer products, reducing reliance on traditional mining and minimizing environmental impact. Urban ore, rich in precious and base metals, offers a sustainable resource by reclaiming materials from landfills, obsolete devices, and industrial scrap.

Tailings Reprocessing

Tailings reprocessing in dredging involves extracting valuable minerals from sediment deposits in water bodies, reducing environmental impact while recovering metals like gold and copper. Urban mining reclaims metals from electronic waste and industrial byproducts, offering a sustainable alternative by reducing reliance on traditional mining and minimizing tailings generation.

Material Circularity

Dredging extracts raw materials from aquatic environments, often disrupting ecosystems and generating waste, whereas urban mining recovers valuable metals from electronic waste, promoting material circularity and reducing reliance on virgin resources. Urban mining enhances sustainability by closing the loop in resource use, enabling higher recycling rates and minimizing environmental impact compared to traditional dredging methods.

Dredging vs Urban mining Infographic

industrydif.com

industrydif.com