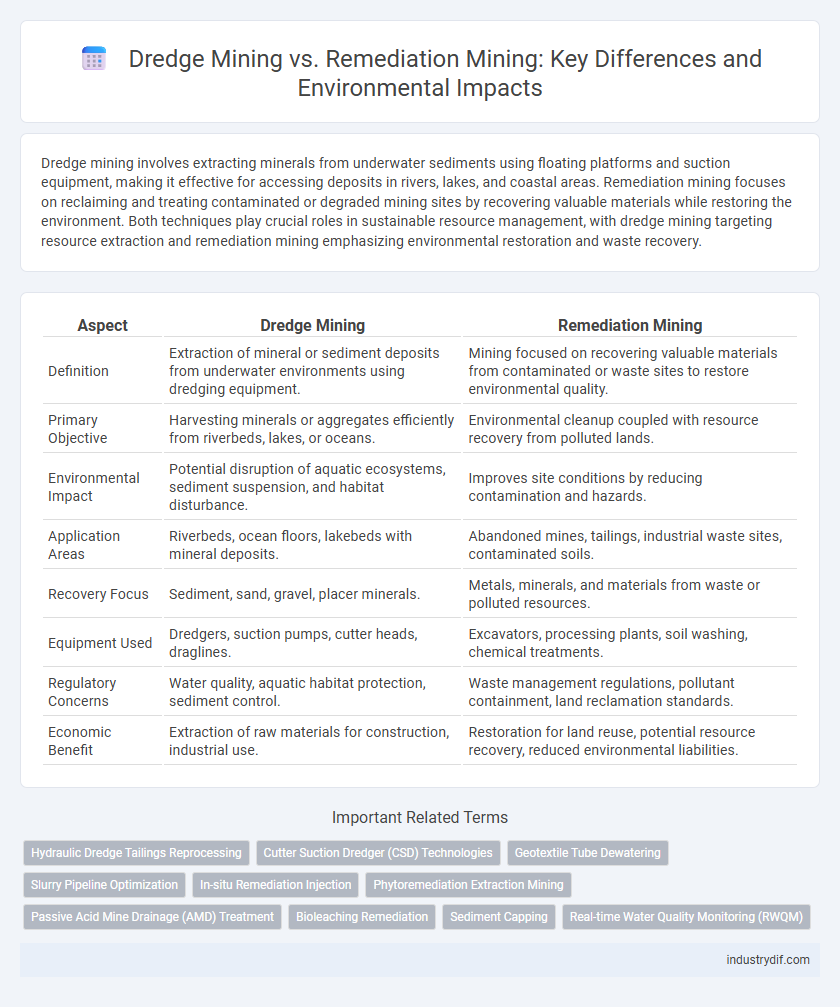

Dredge mining involves extracting minerals from underwater sediments using floating platforms and suction equipment, making it effective for accessing deposits in rivers, lakes, and coastal areas. Remediation mining focuses on reclaiming and treating contaminated or degraded mining sites by recovering valuable materials while restoring the environment. Both techniques play crucial roles in sustainable resource management, with dredge mining targeting resource extraction and remediation mining emphasizing environmental restoration and waste recovery.

Table of Comparison

| Aspect | Dredge Mining | Remediation Mining |

|---|---|---|

| Definition | Extraction of mineral or sediment deposits from underwater environments using dredging equipment. | Mining focused on recovering valuable materials from contaminated or waste sites to restore environmental quality. |

| Primary Objective | Harvesting minerals or aggregates efficiently from riverbeds, lakes, or oceans. | Environmental cleanup coupled with resource recovery from polluted lands. |

| Environmental Impact | Potential disruption of aquatic ecosystems, sediment suspension, and habitat disturbance. | Improves site conditions by reducing contamination and hazards. |

| Application Areas | Riverbeds, ocean floors, lakebeds with mineral deposits. | Abandoned mines, tailings, industrial waste sites, contaminated soils. |

| Recovery Focus | Sediment, sand, gravel, placer minerals. | Metals, minerals, and materials from waste or polluted resources. |

| Equipment Used | Dredgers, suction pumps, cutter heads, draglines. | Excavators, processing plants, soil washing, chemical treatments. |

| Regulatory Concerns | Water quality, aquatic habitat protection, sediment control. | Waste management regulations, pollutant containment, land reclamation standards. |

| Economic Benefit | Extraction of raw materials for construction, industrial use. | Restoration for land reuse, potential resource recovery, reduced environmental liabilities. |

Introduction to Dredge Mining and Remediation Mining

Dredge mining involves extracting mineral deposits from underwater sediments using specialized floating equipment, primarily targeting placer deposits rich in gold, tin, or diamonds. Remediation mining focuses on recovering valuable minerals from previously mined or contaminated sites, helping to mitigate environmental damage and restore ecosystems. Both methods optimize resource extraction while addressing sustainability challenges in modern mining operations.

Fundamental Concepts in Modern Mining Technologies

Dredge mining involves extracting mineral resources from underwater sediments using specialized equipment like suction dredges, targeting placer deposits rich in gold, tin, or diamonds. Remediation mining focuses on recovering valuable materials from mine tailings and waste, employing techniques that minimize environmental impact and promote sustainable resource utilization. Both methods integrate advanced technologies such as remote sensing, automation, and real-time data analysis to enhance efficiency and reduce ecological footprints in modern mining operations.

Methods and Processes: Dredge Mining Explained

Dredge mining involves extracting minerals and sediments from underwater locations by using a floating platform equipped with suction or bucket dredges to gather and transport materials. This method targets riverbeds, lakes, and coastal areas, efficiently recovering gold, tin, or other valuable minerals through continuous excavation and separation processes. In contrast, remediation mining focuses on environmental restoration by targeting contaminated sites to remove toxic substances and rehabilitate ecosystems, utilizing specialized extraction and treatment techniques.

Key Techniques in Remediation Mining

Remediation mining employs key techniques such as bioremediation, where microorganisms break down contaminants, and soil washing, which separates pollutants from soil particles using water or chemical solutions. Phytoremediation utilizes plants to absorb heavy metals and toxins, enhancing site recovery and environmental health. These targeted methods restore mining-impacted sites more sustainably compared to traditional dredge mining, which involves sediment excavation and often disturbs aquatic ecosystems.

Equipment and Technology Comparison

Dredge mining utilizes floating dredges equipped with suction pumps and high-capacity draglines to extract mineral-rich sediments from underwater deposits, emphasizing mechanical excavation and continuous material processing. Remediation mining employs advanced sensor technologies, remote-operated vehicles (ROVs), and selective extraction tools designed to minimize environmental impact while targeting specific contaminants or residual minerals within disturbed sites. The technological innovation in dredge mining prioritizes volume and efficiency, whereas remediation mining focuses on precision, environmental safety, and rehabilitation capabilities.

Environmental Impact: Dredge Mining vs Remediation Mining

Dredge mining often causes significant environmental disruption, including habitat destruction, sediment displacement, and water pollution due to the extraction process in aquatic ecosystems. In contrast, remediation mining focuses on environmental restoration by removing contaminants and rehabilitating degraded mining sites, reducing long-term ecological damage. The choice between dredge and remediation mining directly impacts water quality, biodiversity, and ecosystem health in mining regions.

Regulatory Considerations and Compliance

Dredge mining requires strict adherence to water quality standards and permits under the Clean Water Act due to its direct impact on aquatic ecosystems. Remediation mining focuses on environmental restoration, often involving compliance with EPA guidelines and state-specific remediation laws to mitigate contamination. Both mining types must maintain comprehensive monitoring and reporting protocols to ensure regulatory compliance and avoid legal penalties.

Cost Analysis and Economic Viability

Dredge mining involves extracting minerals from underwater sediments, often requiring significant upfront capital investment in specialized equipment and dredging vessels, making it cost-intensive but efficient for large-scale operations. Remediation mining focuses on recovering valuable materials from previously mined or waste sites, reducing environmental liability and disposal costs while potentially generating revenue, offering a more economically viable option for sites with accessible tailings or waste rock. Comparative cost analysis reveals dredge mining's high operational expenses contrast with remediation mining's lower costs and added value from environmental compliance benefits, influencing project feasibility and investment decisions.

Operational Challenges and Risk Management

Dredge mining faces operational challenges such as equipment maintenance in underwater conditions, sediment management, and fluctuating water levels impacting efficiency, while remediation mining deals with unpredictable contamination levels and waste handling complexities. Risk management in dredge mining prioritizes environmental impact mitigation and worker safety amid aquatic hazards, whereas remediation mining emphasizes containment of toxic substances and compliance with stringent environmental regulations. Both methods require robust monitoring systems to address potential ecological damage and operational disruptions effectively.

Future Trends in Dredge and Remediation Mining

Future trends in dredge and remediation mining emphasize the integration of advanced automation and real-time monitoring technologies to enhance operational efficiency and environmental compliance. Innovations such as AI-driven predictive analytics and eco-friendly sediment processing methods are expected to significantly reduce ecological impact while maximizing resource recovery. The adoption of sustainable practices and regulatory frameworks will continue to shape the evolution of dredge and remediation mining in the coming decade.

Related Important Terms

Hydraulic Dredge Tailings Reprocessing

Hydraulic dredge tailings reprocessing in dredge mining involves extracting valuable minerals from the residual waste deposited in tailings ponds, enhancing resource recovery and reducing environmental impact. Unlike remediation mining, which primarily focuses on site cleanup and pollution reduction, hydraulic dredge tailings reprocessing maximizes economic value by recovering metals such as gold, copper, and rare earth elements from previously processed materials.

Cutter Suction Dredger (CSD) Technologies

Cutter Suction Dredger (CSD) technologies excel in dredge mining by efficiently excavating underwater sediments and minerals using a rotating cutter head combined with high-capacity suction pumps, enabling continuous material extraction from riverbeds, seabeds, and reservoirs. In remediation mining, CSD systems focus on environmental restoration by removing contaminated sediments and pollutants, leveraging precise control and minimal disruption to water ecosystems while reclaiming valuable resources.

Geotextile Tube Dewatering

Dredge mining employs geotextile tube dewatering to efficiently separate solids from water, facilitating sediment containment and allowing for water recycling in mining operations. In contrast, remediation mining utilizes geotextile tube dewatering primarily to treat and stabilize contaminated sediments, enhancing environmental restoration by reducing pollutant dispersion.

Slurry Pipeline Optimization

Dredge mining involves extracting underwater sediments using dredgers, while remediation mining focuses on cleaning contaminated mining sites by removing pollutants. Optimizing slurry pipeline systems in both methods enhances material transport efficiency, reduces energy consumption, and minimizes wear by tailoring flow rates, particle sizes, and pipeline materials to specific mining conditions.

In-situ Remediation Injection

In-situ remediation injection in dredge mining targets sediment contaminants by delivering reactive agents directly into underwater deposits, enhancing pollutant breakdown without extensive excavation. This method contrasts with conventional dredge mining, which physically removes sediments, making in-situ approaches less disruptive and more cost-effective for long-term environmental recovery.

Phytoremediation Extraction Mining

Phytoremediation extraction mining uses specific plant species to absorb and concentrate heavy metals or contaminants from dredge mining sediments, offering a sustainable method to rehabilitate mine-impacted sites. This technique reduces environmental toxicity while enabling the recovery of valuable metals, contrasting with traditional dredge mining that primarily focuses on sediment excavation without ecological restoration.

Passive Acid Mine Drainage (AMD) Treatment

Dredge mining removes contaminated sediments from water bodies, directly reducing sources of passive Acid Mine Drainage (AMD) and improving water quality by physically extracting acidic materials and heavy metals. Remediation mining targets the environmental restoration of AMD-affected sites through techniques such as alkaline amendments and constructed wetlands, promoting passive AMD treatment by neutralizing acidity and precipitating metal contaminants.

Bioleaching Remediation

Dredge mining involves extracting minerals by removing sediments from water bodies, often causing significant ecological disruption, whereas remediation mining employs bioleaching techniques using microorganisms to recover metals from contaminated sites with minimal environmental impact. Bioleaching remediation harnesses bacteria such as Acidithiobacillus ferrooxidans to oxidize sulfide ores, facilitating metal recovery while simultaneously detoxifying polluted soils and water.

Sediment Capping

Dredge mining involves the removal of sediment from water bodies to extract minerals or restore aquatic environments, while remediation mining focuses on rehabilitating contaminated sites by isolating pollutants. Sediment capping in remediation mining employs a layer of clean material to encapsulate contaminated sediments, preventing the spread of toxins and promoting ecosystem recovery.

Real-time Water Quality Monitoring (RWQM)

Dredge mining involves extracting sediments and minerals directly from water bodies, making Real-time Water Quality Monitoring (RWQM) essential to detect turbidity spikes and heavy metal concentrations promptly. In contrast, remediation mining uses RWQM to continuously assess water purity during the restoration of contaminated sites, ensuring compliance with environmental standards and minimizing ecosystem disruption.

Dredge mining vs Remediation mining Infographic

industrydif.com

industrydif.com