Underground mining involves extracting minerals through tunnels and shafts, providing direct access to ore but requiring extensive safety measures and higher operational costs. Bioleaching uses microorganisms to dissolve valuable metals from ores, offering an environmentally friendly alternative with lower energy consumption and reduced emissions. The choice between underground mining and bioleaching depends on ore type, deposit depth, and environmental considerations.

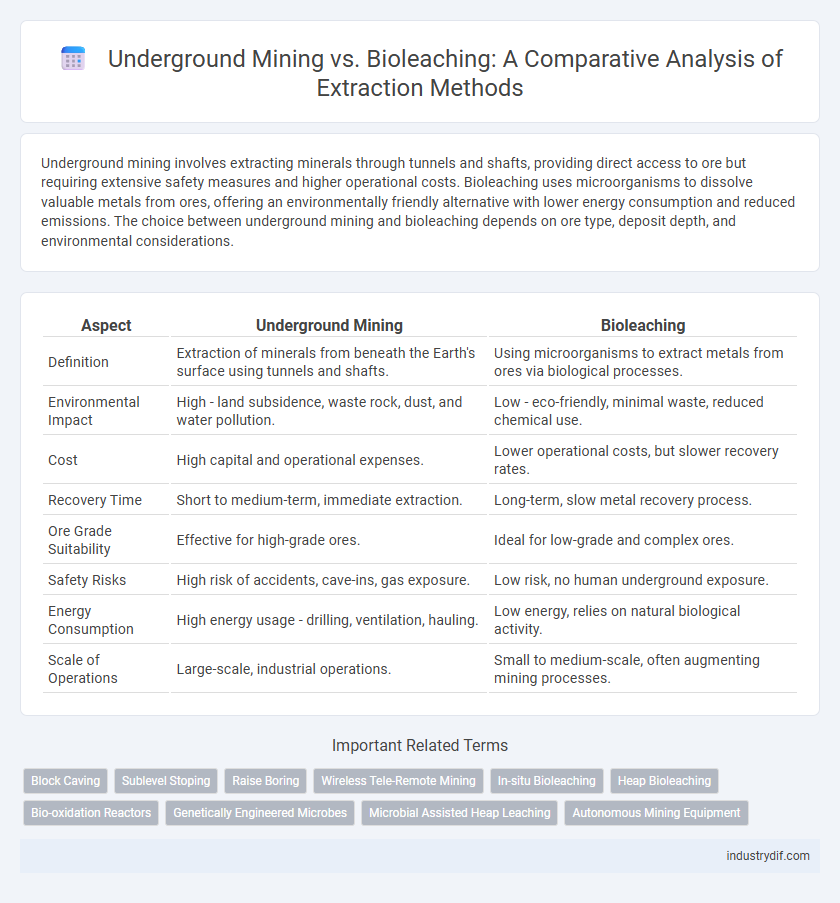

Table of Comparison

| Aspect | Underground Mining | Bioleaching |

|---|---|---|

| Definition | Extraction of minerals from beneath the Earth's surface using tunnels and shafts. | Using microorganisms to extract metals from ores via biological processes. |

| Environmental Impact | High - land subsidence, waste rock, dust, and water pollution. | Low - eco-friendly, minimal waste, reduced chemical use. |

| Cost | High capital and operational expenses. | Lower operational costs, but slower recovery rates. |

| Recovery Time | Short to medium-term, immediate extraction. | Long-term, slow metal recovery process. |

| Ore Grade Suitability | Effective for high-grade ores. | Ideal for low-grade and complex ores. |

| Safety Risks | High risk of accidents, cave-ins, gas exposure. | Low risk, no human underground exposure. |

| Energy Consumption | High energy usage - drilling, ventilation, hauling. | Low energy, relies on natural biological activity. |

| Scale of Operations | Large-scale, industrial operations. | Small to medium-scale, often augmenting mining processes. |

Introduction to Underground Mining and Bioleaching

Underground mining involves extracting minerals from beneath the earth's surface through tunnels and shafts, allowing access to deep ore deposits with minimal surface disturbance. Bioleaching utilizes microorganisms to chemically break down ore, enabling the recovery of metals such as copper, gold, and nickel from low-grade ores without traditional excavation. This innovative technique offers an eco-friendly alternative to conventional underground mining by reducing energy consumption and environmental impact.

Fundamental Principles of Underground Mining

Underground mining involves extracting mineral resources by creating tunnels or shafts below the earth's surface, targeting ore bodies that are deep and economically viable. This method relies on excavation techniques such as cut-and-fill, room-and-pillar, and block caving to maintain ground stability and optimize ore recovery. The fundamental principles emphasize safety, ventilation, ground control, and efficient ore extraction to maximize yield while minimizing environmental impact and operational risks.

Core Processes in Bioleaching

Bioleaching utilizes microorganisms to oxidize and solubilize metals from ores, harnessing bacterial metabolism to extract valuable metals like copper and gold more sustainably than traditional underground mining. Core processes in bioleaching include the oxidation of sulfide minerals by bacteria such as Acidithiobacillus ferrooxidans, followed by metal solubilization and recovery from the leachate solution. This biotechnological approach reduces environmental impact by minimizing physical excavation, lowering energy consumption, and enabling metal extraction from low-grade ores.

Comparative Environmental Impacts

Underground mining often results in significant environmental disturbances such as groundwater contamination, habitat destruction, and air pollution from diesel emissions. Bioleaching offers a more environmentally sustainable alternative by using microorganisms to extract metals, reducing the need for harmful chemicals and minimizing soil and water contamination. Comparative studies indicate that bioleaching has a lower carbon footprint and reduced energy consumption compared to conventional underground mining methods.

Economic Considerations: Cost and Efficiency

Underground mining demands significant upfront investment in infrastructure, equipment, and labor, resulting in higher operational costs but offers faster ore extraction rates with immediate revenue potential. Bioleaching presents a cost-effective alternative by utilizing microorganisms to extract metals from low-grade ores and waste materials, reducing energy consumption and environmental remediation expenses over extended timeframes. Economic efficiency in underground mining hinges on ore grade and deposit accessibility, whereas bioleaching excels in processing complex ores with lower capital expenditure but longer extraction periods.

Ore Types Suitable for Each Method

Underground mining is ideal for extracting high-grade, hard rock ores such as gold, copper, and zinc found at significant depths, where traditional surface methods are impractical. Bioleaching is more effective for low-grade ores and sulfide minerals like chalcopyrite and pentlandite, leveraging microbial activity to extract metals in a cost-efficient and environmentally friendly manner. Each method's suitability depends on ore composition, depth, and economic factors associated with mineral processing and recovery rates.

Technological Requirements and Innovations

Underground mining demands extensive infrastructure such as ventilation systems, reinforced tunnels, and heavy machinery for ore extraction and safety management, requiring skilled labor and advanced geotechnical monitoring technology. Bioleaching relies on microbial processes and controlled environmental conditions within bioreactors or heap leaching setups, necessitating innovations in biotechnology, process control, and environmental engineering. Recent advancements include automation in underground operations for enhanced efficiency and the development of genetically optimized microorganisms to increase metal recovery rates in bioleaching.

Safety and Health Challenges

Underground mining poses significant safety risks including cave-ins, toxic gas exposure, and limited ventilation, resulting in high incidence of respiratory diseases and accidents among miners. Bioleaching offers a safer alternative by using microorganisms to extract metals from ores, reducing the need for hazardous physical labor and minimizing exposure to harmful chemicals and dust. Despite lower immediate physical dangers, bioleaching processes require careful monitoring to manage potential environmental impacts and microbial hazards.

Case Studies: Successful Applications

Case studies reveal underground mining excels in extracting deep, high-grade ore bodies with established infrastructure, exemplified by the extensive operations at the Kidd Mine in Canada, which operates at depths exceeding 3,000 meters with high productivity and safety standards. Bioleaching demonstrates success in low-grade, complex sulfide ores, as seen in the Escondida mine in Chile, where bioleaching improves copper recovery while reducing environmental impact and operational costs. These real-world applications highlight underground mining's dominance in depth and grade, whereas bioleaching offers sustainable solutions for ore previously considered uneconomical.

Future Trends in Subsurface Extraction Methods

Underground mining is evolving with advanced automation, real-time monitoring, and improved ventilation systems enhancing safety and efficiency. Bioleaching leverages microorganisms to extract metals, offering an eco-friendly alternative with lower energy consumption and reduced environmental footprint. Future trends emphasize integrating bioleaching with traditional underground mining to optimize resource recovery and minimize ecological impact in subsurface extraction.

Related Important Terms

Block Caving

Block caving, an efficient underground mining method, involves controlled collapse of ore bodies to extract large volumes economically, unlike bioleaching which relies on microbial oxidation to extract metals from low-grade ores. This mechanized approach accelerates mineral recovery in massive, low-grade deposits while bioleaching offers an environmentally sustainable alternative for metal extraction, particularly in complex sulfide ores unsuitable for conventional mining.

Sublevel Stoping

Sublevel stoping, a prevalent underground mining method, efficiently extracts ore by creating horizontal levels for controlled blasting and material removal, optimizing ore recovery and safety in stable rock conditions. Bioleaching offers an environmentally friendly alternative by using microorganisms to extract metals from low-grade ores without extensive excavation, but is less suitable for the high-grade ore extraction and precision control achieved in sublevel stoping.

Raise Boring

Raise boring in underground mining offers precise excavation of vertical shafts with minimal ground disturbance and enhanced safety compared to traditional drilling methods. Bioleaching leverages microbial activity to extract metals, providing an environmentally friendly alternative, but lacks the mechanical speed and structural control achievable with raise boring techniques.

Wireless Tele-Remote Mining

Wireless tele-remote mining technology enhances underground mining operations by enabling remote control of heavy machinery, increasing safety and operational efficiency in hazardous environments. Compared to bioleaching, which relies on microbial processes for metal extraction, tele-remote mining offers immediate operational control and precision, significantly reducing human exposure to underground risks.

In-situ Bioleaching

In-situ bioleaching offers a sustainable alternative to traditional underground mining by utilizing microorganisms to extract metals directly from ore bodies without extensive excavation, minimizing environmental disruption and lowering operational costs. This method enhances metal recovery efficiency in low-grade ores while reducing waste generation and energy consumption compared to conventional underground mining techniques.

Heap Bioleaching

Heap bioleaching offers an environmentally sustainable alternative to traditional underground mining by utilizing bacteria to extract metals from low-grade ores through controlled microbial oxidation. This process significantly reduces operational costs and environmental impact while enabling the recovery of valuable metals such as copper and gold from tailings and stockpiled material.

Bio-oxidation Reactors

Bio-oxidation reactors enhance bioleaching efficiency by accelerating the oxidation of sulfide minerals through microbial activity, offering a sustainable alternative to traditional underground mining. These reactors optimize metal recovery from low-grade ores with reduced environmental impact compared to conventional extraction methods.

Genetically Engineered Microbes

Genetically engineered microbes enhance bioleaching by increasing the efficiency of metal extraction from low-grade ores, offering a sustainable alternative to traditional underground mining that often involves extensive excavation and environmental disruption. These microbes can be tailored to target specific minerals, improving recovery rates while minimizing the ecological footprint compared to conventional mining methods.

Microbial Assisted Heap Leaching

Microbial Assisted Heap Leaching leverages specific bacteria to enhance metal recovery from low-grade ores, offering a cost-effective and environmentally sustainable alternative to traditional underground mining techniques. This bioleaching method improves the dissolution rate of metals such as copper and gold, reducing the need for extensive excavation and minimizing surface disturbance.

Autonomous Mining Equipment

Autonomous mining equipment in underground mining enhances operational safety and efficiency by enabling remote control and real-time data analytics in hazardous subsurface environments. In contrast, bioleaching relies on microorganisms to extract metals from ores with minimal machinery, reducing the need for heavy autonomous equipment but extending processing time.

Underground Mining vs Bioleaching Infographic

industrydif.com

industrydif.com