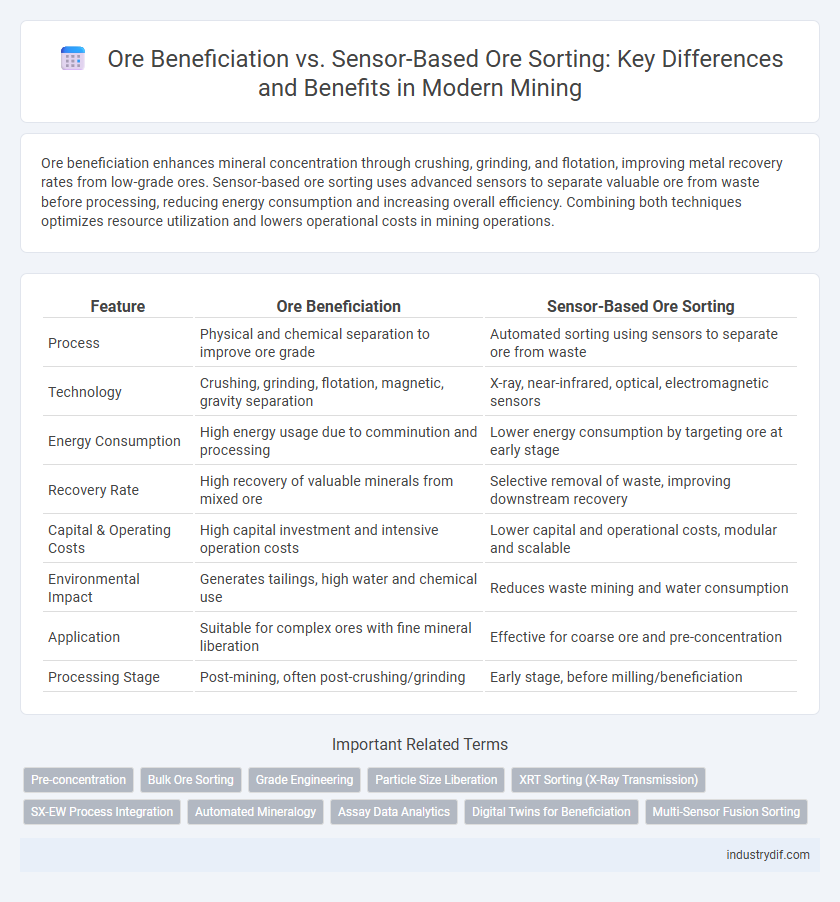

Ore beneficiation enhances mineral concentration through crushing, grinding, and flotation, improving metal recovery rates from low-grade ores. Sensor-based ore sorting uses advanced sensors to separate valuable ore from waste before processing, reducing energy consumption and increasing overall efficiency. Combining both techniques optimizes resource utilization and lowers operational costs in mining operations.

Table of Comparison

| Feature | Ore Beneficiation | Sensor-Based Ore Sorting |

|---|---|---|

| Process | Physical and chemical separation to improve ore grade | Automated sorting using sensors to separate ore from waste |

| Technology | Crushing, grinding, flotation, magnetic, gravity separation | X-ray, near-infrared, optical, electromagnetic sensors |

| Energy Consumption | High energy usage due to comminution and processing | Lower energy consumption by targeting ore at early stage |

| Recovery Rate | High recovery of valuable minerals from mixed ore | Selective removal of waste, improving downstream recovery |

| Capital & Operating Costs | High capital investment and intensive operation costs | Lower capital and operational costs, modular and scalable |

| Environmental Impact | Generates tailings, high water and chemical use | Reduces waste mining and water consumption |

| Application | Suitable for complex ores with fine mineral liberation | Effective for coarse ore and pre-concentration |

| Processing Stage | Post-mining, often post-crushing/grinding | Early stage, before milling/beneficiation |

Introduction to Ore Beneficiation and Sensor-Based Ore Sorting

Ore beneficiation enhances mineral concentrate quality by physically or chemically separating valuable minerals from gangue, increasing overall metal recovery and reducing processing costs. Sensor-based ore sorting uses advanced technologies like X-ray transmission, near-infrared spectroscopy, and electromagnetic sensors to identify and separate ore particles based on their physical and chemical properties before traditional processing. Both methods improve efficiency by reducing waste and optimizing downstream operations in mining.

Fundamental Principles of Ore Beneficiation

Ore beneficiation involves physical and chemical processes that improve ore quality by removing impurities and enhancing mineral concentration, typically through crushing, grinding, flotation, and magnetic separation. The fundamental principles rely on exploiting differences in mineral properties such as density, magnetic susceptibility, and surface chemistry to achieve selective separation. This contrasts with sensor-based ore sorting, which employs real-time detection technologies like X-ray or near-infrared sensors to classify and separate ore particles based on their physical or chemical characteristics before further processing.

Core Technologies in Sensor-Based Ore Sorting

Sensor-based ore sorting relies on advanced core technologies such as X-ray transmission (XRT), near-infrared (NIR) spectroscopy, and electromagnetic induction to accurately differentiate ore particles based on composition, density, and moisture content. These technologies enable real-time, precise identification and separation of valuable minerals from waste rock, enhancing throughput and reducing processing costs compared to traditional ore beneficiation methods. The integration of machine learning algorithms further optimizes sorting accuracy by continuously analyzing sensor data to adapt to ore variability.

Efficiency Comparison: Traditional vs Digital Approaches

Ore beneficiation relies on physical and chemical processes to separate valuable minerals from gangue, often requiring extensive energy and water consumption. Sensor-based ore sorting uses advanced technologies like X-ray, near-infrared, or laser sensors to rapidly identify and segregate ore particles, significantly reducing waste and operational costs. Digital approaches enhance overall efficiency by increasing recovery rates and minimizing environmental impact compared to traditional beneficiation methods.

Environmental Impacts: Water, Energy, and Waste

Ore beneficiation techniques reduce environmental footprints by optimizing water and energy use, minimizing waste generation through efficient mineral separation. Sensor-based ore sorting enhances environmental sustainability by selectively processing ore, significantly lowering water consumption and reducing energy requirements compared to conventional beneficiation. Both methods contribute to waste stream reduction, but sensor-based sorting offers a more precise approach that decreases tailings volume and associated environmental hazards.

Economic Considerations and Cost Efficiency

Ore beneficiation and sensor-based ore sorting present distinct economic considerations in mining operations, with beneficiation often involving higher energy consumption and complex processing infrastructure, leading to increased operational costs. Sensor-based ore sorting reduces waste volume before grinding, significantly lowering energy use and improving mill throughput, resulting in cost efficiencies and higher return on investment. Choosing the optimal method depends on ore characteristics, scale of operation, and cost-benefit analyses focusing on capital expenditure, operational expenditure, and potential revenue gain from improved ore grade.

Scalability and Integration in Mining Operations

Ore beneficiation offers high scalability for large-scale mining operations through established physical and chemical processes, enabling the treatment of vast ore volumes with consistent quality improvement. Sensor-based ore sorting integrates advanced real-time detection technologies such as X-ray transmission and near-infrared sensors, allowing selective separation at early processing stages and reducing energy and water consumption. Combining these methods enhances overall operational efficiency, with sensor-based sorting providing pre-concentration that optimizes downstream beneficiation throughput and resource utilization.

Quality Control and Metal Recovery Rates

Ore beneficiation enhances quality control by employing techniques such as flotation, magnetic separation, and gravity concentration to increase metal recovery rates by selectively concentrating valuable minerals. Sensor-based ore sorting uses advanced technologies like X-ray transmission, near-infrared, and laser-induced breakdown spectroscopy to identify and sort ore based on its physical and chemical properties, improving feed quality and reducing processing costs. Combining both methods can optimize metal recovery rates and maintain consistent product quality throughout the mining operation.

Case Studies: Success Stories and Challenges

Case studies in ore beneficiation highlight improved metal recovery and reduced processing costs through techniques like flotation and magnetic separation, demonstrating success in complex ore bodies. Sensor-based ore sorting case studies reveal enhanced throughput and waste reduction by using X-ray transmission and near-infrared sensors to pre-concentrate ores, though challenges include sensor calibration and variable ore mineralogy. Both methods improve resource efficiency, with beneficiation excelling in fine mineral separation and sensor-based sorting optimizing feed quality before milling.

Future Trends in Ore Processing Technologies

Future trends in ore processing technologies emphasize enhanced efficiency and sustainability, with sensor-based ore sorting gaining traction due to its real-time, precise mineral discrimination capabilities that reduce waste and energy consumption. Ore beneficiation remains vital for upgrading ore quality but is increasingly integrated with sensor-based methods to optimize feedstock and lower processing costs. Advancements in AI and machine learning accelerate sensor-based sorting accuracy, paving the way for smarter, more adaptive ore processing solutions.

Related Important Terms

Pre-concentration

Ore beneficiation enhances mineral recovery by employing techniques such as flotation and gravity separation to increase ore grade, while sensor-based ore sorting serves as an effective pre-concentration method that uses real-time detection technologies like X-ray transmission and near-infrared sensors to separate valuable minerals from waste rock before crushing. Sensor-based sorting reduces energy consumption and processing costs by rejecting low-grade material early, optimizing downstream beneficiation efficiency and overall resource utilization.

Bulk Ore Sorting

Bulk ore sorting enhances ore beneficiation by pre-concentrating ore before processing, significantly reducing energy consumption and increasing overall recovery rates. This sensor-based ore sorting technology uses advanced sensors to differentiate ore from waste, optimizing feed quality and lowering operational costs in mining operations.

Grade Engineering

Ore beneficiation enhances the mineral value by upgrading ore through physical or chemical processes, improving concentrate grade and recovery rates. Sensor-based ore sorting selectively separates valuable minerals from gangue using advanced sensors, enabling precise grade engineering and reducing processing costs.

Particle Size Liberation

Ore beneficiation enhances mineral recovery by processing finely crushed particles to maximize liberation, often targeting particle sizes below 0.5 mm for optimal separation. Sensor-based ore sorting efficiently removes gangue by detecting and rejecting larger liberated particles typically above 1 mm, reducing downstream processing volume and improving throughput.

XRT Sorting (X-Ray Transmission)

Ore beneficiation enhances mineral content by improving ore quality through processes like crushing, grinding, and flotation, optimizing overall metal recovery. XRT sorting, a sensor-based ore sorting technique using X-ray transmission, precisely differentiates materials based on density and atomic number, enabling efficient separation and reducing downstream processing costs.

SX-EW Process Integration

Ore beneficiation enhances ore quality by progressively increasing metal concentration through physical or chemical methods, improving feed material for the SX-EW process to achieve higher copper recovery and purity. Sensor-based ore sorting selectively rejects low-grade material using real-time data, optimizing ore feed by reducing processing volume and energy consumption, thus complementing SX-EW integration for cost-effective and environmentally sustainable copper extraction.

Automated Mineralogy

Automated mineralogy enables precise characterization of ore mineral content and liberation, enhancing the efficiency of ore beneficiation processes compared to sensor-based ore sorting by providing detailed mineralogical data for optimized separation. Advanced tools like QEMSCAN and MLA integrate automated mineralogy with sensor-based sorting, improving grade control and reducing waste in mining operations.

Assay Data Analytics

Ore beneficiation enhances mineral value through physicochemical processes, whereas sensor-based ore sorting utilizes real-time assay data analytics to categorize and separate ore particles based on precise geochemical and mineralogical signatures. Integrating assay data analytics in sensor-based sorting increases recovery rates and reduces waste by accurately targeting valuable ore zones, optimizing processing efficiency in mining operations.

Digital Twins for Beneficiation

Digital twins in ore beneficiation enable real-time simulation and optimization of processes, enhancing recovery rates and reducing energy consumption compared to traditional methods. Sensor-based ore sorting benefits from digital twin integration by providing detailed mineralogical data that refines sorting criteria and improves overall ore processing efficiency.

Multi-Sensor Fusion Sorting

Multi-sensor fusion sorting enhances ore beneficiation by integrating data from various sensors such as X-ray fluorescence, near-infrared, and laser-induced breakdown spectroscopy to improve accuracy in ore grade determination and impurity removal. This advanced sensor-based ore sorting reduces energy consumption and processing costs while increasing recovery rates by precisely distinguishing valuable minerals from gangue at an early stage.

Ore Beneficiation vs Sensor-Based Ore Sorting Infographic

industrydif.com

industrydif.com