Heap leaching is a cost-effective mining technique that involves stacking ore and applying chemical solutions to dissolve precious metals, making it efficient for low-grade ores. Invisible gold extraction targets microscopic gold particles embedded within sulfide minerals using advanced hydrometallurgical methods, enabling recovery from ores once considered uneconomical. Comparing both methods, heap leaching offers simplicity and scalability, while invisible gold extraction provides higher recovery rates for complex or refractory ores.

Table of Comparison

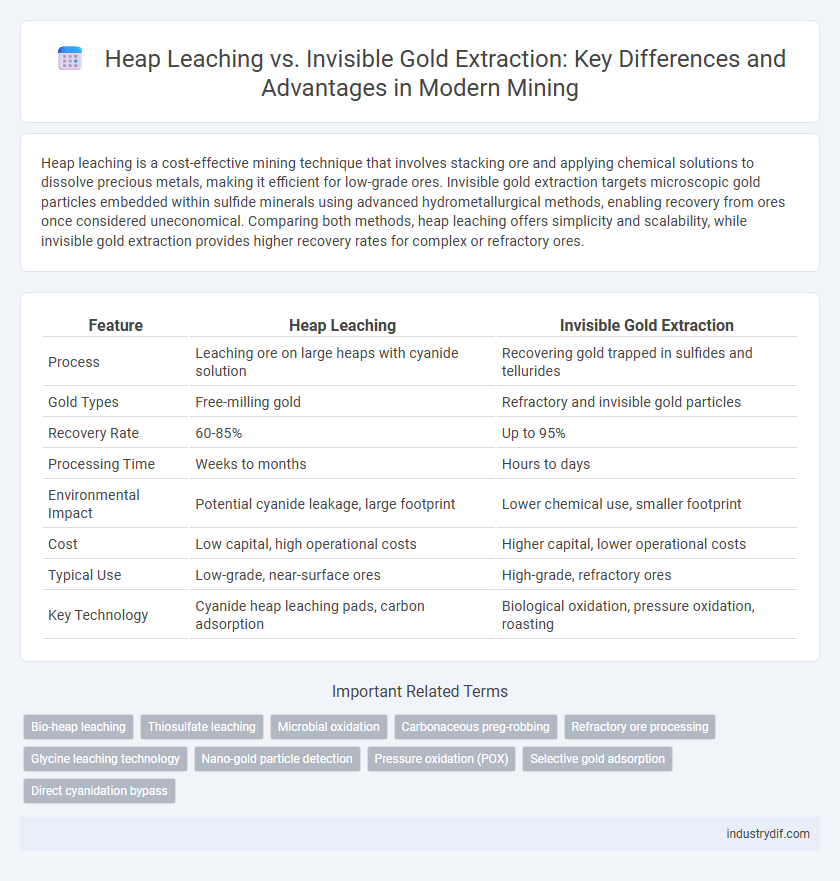

| Feature | Heap Leaching | Invisible Gold Extraction |

|---|---|---|

| Process | Leaching ore on large heaps with cyanide solution | Recovering gold trapped in sulfides and tellurides |

| Gold Types | Free-milling gold | Refractory and invisible gold particles |

| Recovery Rate | 60-85% | Up to 95% |

| Processing Time | Weeks to months | Hours to days |

| Environmental Impact | Potential cyanide leakage, large footprint | Lower chemical use, smaller footprint |

| Cost | Low capital, high operational costs | Higher capital, lower operational costs |

| Typical Use | Low-grade, near-surface ores | High-grade, refractory ores |

| Key Technology | Cyanide heap leaching pads, carbon adsorption | Biological oxidation, pressure oxidation, roasting |

Introduction to Heap Leaching and Invisible Gold Extraction

Heap leaching is a cost-effective mining technique where crushed ore is piled and irrigated with chemical solutions to dissolve valuable metals like gold, facilitating extraction from low-grade ores. Invisible gold extraction targets submicroscopic gold particles embedded within sulfide minerals, employing advanced methods such as pressure oxidation or bio-oxidation to liberate gold before leaching. These complementary processes enhance gold recovery efficiency from complex ore deposits.

Historical Development of Gold Recovery Techniques

Heap leaching revolutionized gold recovery by enabling low-grade ore processing through the 1970s, dramatically improving extraction efficiency compared to traditional gravity and amalgamation methods. Invisible gold extraction emerged from advances in analytical chemistry and mineralogy in the late 20th century, targeting sub-microscopic gold particles in complex sulfide ores previously deemed uneconomical. These developments reflect a trajectory from coarse, mechanical separation to sophisticated chemical and mineralogical techniques that maximize yield and reduce environmental impact.

Fundamentals of Heap Leaching in Mining

Heap leaching in mining involves stacking ore in large heaps and applying leaching solutions to extract valuable metals like gold, copper, or silver through percolation. This cost-effective, low-energy method facilitates the recovery of metals from low-grade ores by promoting chemically reactive conditions that dissolve metals and enable their collection in solution form. Key fundamentals include ore permeability, optimal heap structure, solution chemistry, and effective control of environmental factors to maximize metal recovery rates.

Invisible Gold Extraction: Definition and Significance

Invisible gold extraction refers to the process of recovering gold particles that are not visible to the naked eye, often locked within mineral matrices or sulfide ores. This method is significant in mining because it enhances overall gold recovery rates, especially from refractory ores that traditional methods like heap leaching cannot effectively treat. Advanced techniques such as bioleaching, pressure oxidation, and ultrafine grinding facilitate the liberation of invisible gold, making extraction more efficient and environmentally sustainable.

Process Flowchart: Heap Leaching vs Invisible Gold Extraction

Heap leaching process flowchart involves ore stacking, application of leaching solutions, percolation for gold dissolution, and recovery via adsorption or precipitation. Invisible gold extraction flowchart includes ore grinding, concentration using flotation or gravity methods, followed by chemical treatment such as cyanidation or roasting. Comparing the two, heap leaching offers low-cost, large-scale processing while invisible gold extraction targets fine, disseminated gold requiring more complex and precise recovery steps.

Recovery Efficiency and Yield Comparison

Heap leaching achieves recovery efficiencies ranging from 60% to 85% for gold ores, making it a cost-effective method for low-grade deposits, while invisible gold extraction methods, such as cyanide leaching combined with ultra-fine grinding, can push recovery rates above 90%. Yield comparison shows heap leaching yields depend heavily on ore permeability and gold particle size, whereas invisible gold extraction targets sub-micron gold particles often missed by conventional methods, resulting in higher overall gold recovery. Optimizing reagent usage and process control in invisible gold extraction enhances recovery efficiency, especially in refractory ores containing invisible gold locked within sulfide minerals.

Environmental Impact: Heap Leaching vs Invisible Gold

Heap leaching poses significant environmental risks due to the potential for cyanide and heavy metal contamination of soil and groundwater, affecting local ecosystems and water sources. Invisible gold extraction methods, often involving advanced chemical or biochemical processes, tend to minimize toxic waste production and reduce harmful emissions, making them more sustainable options. Monitoring and managing the environmental footprint of both techniques remain critical for responsible mining operations.

Cost Analysis and Operational Considerations

Heap leaching offers a cost-effective extraction method by utilizing low-grade ore and reducing energy consumption, making it favorable for large-scale gold mining operations. Invisible gold extraction involves more complex, precise processing techniques such as ultrafine grinding and chemical reagents, resulting in higher operational costs and specialized equipment requirements. Evaluating factors like ore grade, processing time, and environmental impact is crucial to determine the most economically viable extraction approach.

Technological Innovations in Gold Extraction

Heap leaching employs low-cost, large-scale chemical processes using cyanide solutions to efficiently extract gold from low-grade ore, while invisible gold extraction leverages advanced nanotechnology and hydrometallurgical techniques to recover ultra-fine gold particles often missed by conventional methods. Innovations such as bio-heap leaching, integrating microbes to enhance metal recovery, and sensor-based ore characterization accelerate extraction rates and increase yield precision. Emerging technologies focus on environmentally sustainable reagents and real-time monitoring systems, transforming gold recovery efficiency and minimizing ecological impact in mining operations.

Future Trends and Industry Outlook

Heap leaching technology is evolving with advancements in bioleaching and improved chemical agents, driving higher recovery rates and reduced environmental impact in gold mining. Invisible gold extraction is gaining momentum through nanotechnology and enhanced microscopy, allowing detection and recovery of ultra-fine gold particles previously undetectable. Industry outlook forecasts integration of AI-driven process optimization and sustainable practices as key growth factors for both heap leaching and invisible gold extraction methods.

Related Important Terms

Bio-heap leaching

Bio-heap leaching utilizes microorganisms to enhance gold recovery from low-grade ores by biologically oxidizing sulfide minerals, improving the efficiency and environmental sustainability compared to traditional heap leaching methods. Unlike invisible gold extraction, which targets submicroscopic gold particles within sulfide matrices, bio-heap leaching leverages microbial activity to liberate these particles, enabling more effective gold recovery in mining operations.

Thiosulfate leaching

Thiosulfate leaching offers an eco-friendly alternative to cyanide heap leaching by effectively extracting gold from refractory ores with lower toxicity and reduced environmental impact. This innovative method enhances gold recovery rates in heap leaching processes, especially for ores containing preg-robbing carbonaceous materials where traditional cyanide leaching struggles.

Microbial oxidation

Heap leaching utilizes microbial oxidation to break down sulfide minerals, enhancing gold recovery by converting complex ores into solvable forms, whereas invisible gold extraction relies on microbial processes to liberate gold trapped within mineral matrices without visible gold particles. Microbial oxidation in heap leaching involves bacteria such as Acidithiobacillus ferrooxidans, which accelerates sulfide breakdown, significantly increasing gold bioavailability compared to conventional chemical methods.

Carbonaceous preg-robbing

Heap leaching efficiency declines significantly in carbonaceous preg-robbing ores due to the adsorption of dissolved gold onto organic carbon, which reduces gold recovery rates. Invisible gold extraction techniques, such as flotation or ultra-fine grinding, target sub-micron gold particles occluded within minerals, improving recovery by liberating gold that heap leaching cannot access.

Refractory ore processing

Heap leaching is a cost-effective technique suitable for oxide ores but shows low recovery rates with refractory ores due to their complex mineral matrix, requiring alternative methods like invisible gold extraction which targets submicroscopic gold particles embedded in sulfide minerals. Invisible gold extraction involves advanced processes such as bio-oxidation or pressure oxidation to liberate gold from refractory ore matrices, significantly improving recovery efficiency compared to conventional heap leaching.

Glycine leaching technology

Glycine leaching technology offers a sustainable and environmentally friendly alternative to traditional heap leaching methods, enhancing gold recovery rates while minimizing toxic chemical usage such as cyanide. This innovative process utilizes the amino acid glycine as a biodegradable lixiviant, improving the extraction efficiency of invisible gold particles from low-grade ores and refractory materials.

Nano-gold particle detection

Heap leaching efficiently recovers gold from low-grade ores but faces challenges in detecting nano-gold particles due to their minute size and dispersion within the ore matrix. Invisible gold extraction employs advanced analytical techniques such as electron microscopy and laser ablation ICP-MS to identify and quantify nano-gold particles, enhancing recovery strategies for refractory ores.

Pressure oxidation (POX)

Pressure oxidation (POX) enhances gold recovery in refractory ores by breaking down sulfide minerals before heap leaching, significantly boosting extraction efficiency. Unlike invisible gold extraction, POX involves high-temperature and high-pressure conditions to oxidize sulfides, improving gold liberation and subsequent leaching performance.

Selective gold adsorption

Heap leaching enables large-scale gold recovery by percolating cyanide solution through crushed ore, whereas invisible gold extraction targets submicroscopic gold particles bound within sulfide minerals using advanced oxidative and bioleaching techniques. Selective gold adsorption in heap leaching relies on carbon-in-pulp or carbon-in-leach processes to efficiently capture dissolved gold from the pregnant leach solution, while invisible gold extraction methods enhance liberation of gold at a molecular level for improved recovery rates.

Direct cyanidation bypass

Heap leaching accelerates gold recovery by stacking ore and irrigating it with cyanide solutions, whereas invisible gold extraction involves direct cyanidation bypass techniques to dissolve ultra-fine gold particles without prior milling. Direct cyanidation bypass significantly reduces processing time and energy costs, enhancing recovery rates especially in low-grade ores with refractory gold forms.

Heap Leaching vs Invisible Gold Extraction Infographic

industrydif.com

industrydif.com