Bioreactors provide controlled environments that enhance cell growth and nutrient distribution, making them ideal for large-scale tissue production. Organoid culture mimics the complex 3D architecture of organs, enabling more accurate modeling of human physiology and disease. Comparing bioreactors and organoid culture highlights the balance between scalable tissue engineering and physiologically relevant models for scientific research.

Table of Comparison

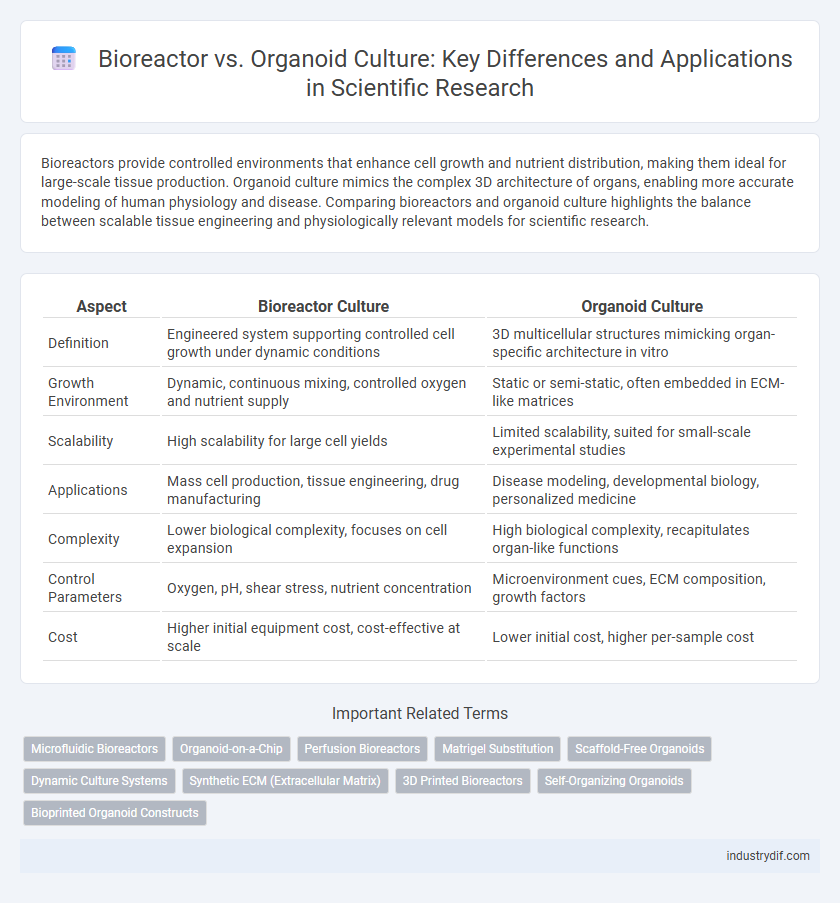

| Aspect | Bioreactor Culture | Organoid Culture |

|---|---|---|

| Definition | Engineered system supporting controlled cell growth under dynamic conditions | 3D multicellular structures mimicking organ-specific architecture in vitro |

| Growth Environment | Dynamic, continuous mixing, controlled oxygen and nutrient supply | Static or semi-static, often embedded in ECM-like matrices |

| Scalability | High scalability for large cell yields | Limited scalability, suited for small-scale experimental studies |

| Applications | Mass cell production, tissue engineering, drug manufacturing | Disease modeling, developmental biology, personalized medicine |

| Complexity | Lower biological complexity, focuses on cell expansion | High biological complexity, recapitulates organ-like functions |

| Control Parameters | Oxygen, pH, shear stress, nutrient concentration | Microenvironment cues, ECM composition, growth factors |

| Cost | Higher initial equipment cost, cost-effective at scale | Lower initial cost, higher per-sample cost |

Introduction to Bioreactors and Organoid Culture

Bioreactors provide a controlled environment for the growth of cells and tissues, enabling precise regulation of parameters like oxygen concentration, pH, and nutrient supply to optimize cell proliferation and differentiation. Organoid culture involves the three-dimensional growth of stem cells into miniaturized, functional tissue models that replicate key structural and functional characteristics of organs. Combining bioreactor technology with organoid culture enhances scalability, improves nutrient and waste exchange, and supports complex tissue maturation for advanced scientific research and therapeutic applications.

Definitions: Bioreactor Systems vs Organoid Models

Bioreactor systems are engineered environments designed to provide controlled physical and chemical conditions that promote cell growth, differentiation, and functionality on a large scale. Organoid models are three-dimensional multicellular structures derived from stem cells that mimic the architecture and function of real organs, offering a more physiologically relevant model for studying development and disease. While bioreactors optimize dynamic culture parameters such as oxygen concentration, nutrient flow, and mechanical stimulation, organoids focus on replicating tissue-specific complexity and cellular interactions in vitro.

Historical Development of Bioreactors and Organoids

The historical development of bioreactors dates back to the early 20th century when they were primarily designed for large-scale fermentation in industrial microbiology, evolving into sophisticated systems supporting cell growth and tissue engineering by enhancing nutrient delivery and environmental control. Organoid culture emerged more recently, gaining momentum in the early 21st century with advances in stem cell biology and 3D cell culture techniques, enabling the self-organization of stem cells into miniaturized, simplified versions of organs that recapitulate key structural and functional features. The convergence of these technologies reflects a shift from traditional two-dimensional cultures to dynamic, three-dimensional systems that more accurately mimic in vivo conditions for biomedical research and therapeutic development.

Core Principles of Bioreactor Technology

Bioreactor technology in cell culture focuses on providing precise control over environmental parameters such as oxygen levels, pH, temperature, and nutrient supply to optimize cell growth and function. Unlike static organoid cultures, bioreactors enable dynamic mixing and perfusion, enhancing mass transfer and mimicking physiological shear stress. This controlled environment supports scalable production and reproducibility essential for tissue engineering and regenerative medicine applications.

Fundamental Concepts in Organoid Culture

Organoid culture involves growing miniaturized and simplified versions of organs derived from stem cells, enabling the study of organ development and disease in a controlled environment. Bioreactor systems enhance organoid culture by providing dynamic conditions like controlled nutrient flow, oxygenation, and mechanical forces, which improve tissue maturation and viability. Understanding stem cell differentiation, extracellular matrix composition, and microenvironmental cues is fundamental to optimizing organoid development in both static and bioreactor cultures.

Applications in Tissue Engineering and Regenerative Medicine

Bioreactor culture enhances tissue engineering by providing dynamic environmental control, improving nutrient delivery, and promoting cell proliferation and differentiation in large-scale constructs. Organoid culture replicates complex tissue architecture and cellular heterogeneity, enabling personalized regenerative medicine through patient-specific disease modeling and drug screening. Combining bioreactors with organoid systems optimizes functional tissue development for transplantation and therapeutic applications.

Comparative Analysis: Efficiency and Scalability

Bioreactor cultures offer superior scalability and controlled environmental conditions, facilitating high-density cell growth and uniform nutrient distribution, which enhances overall efficiency compared to traditional organoid cultures. Organoid cultures, while providing more physiologically relevant tissue structures, face limitations in scalability and reproducibility due to their inherent complexity and reliance on manual handling. Advances in bioreactor systems integrating automation and real-time monitoring address these challenges, making them more suitable for large-scale applications in drug screening and regenerative medicine.

Challenges in Bioreactor and Organoid Cultivation

Bioreactor cultivation faces challenges such as maintaining uniform nutrient distribution, controlling shear stress to prevent cell damage, and achieving scalability for large-scale tissue production. Organoid culture struggles with heterogeneity in size and cellular composition, limited vascularization affecting nutrient delivery, and difficulty in replicating the complex in vivo microenvironment. Both systems require optimization of physical and chemical parameters to enhance reproducibility and functional maturation.

Advances in Bioprocessing and 3D Culture Techniques

Bioreactor systems enable dynamic control of environmental parameters such as oxygen, pH, and nutrient supply, enhancing cell proliferation and differentiation in 3D cultures. Organoid culture techniques replicate tissue-specific architecture and function, allowing for more physiologically relevant models in disease research and drug testing. Advances in bioprocessing integrate these systems to optimize scalability, reproducibility, and functional maturation of cultured tissues.

Future Prospects: Integrating Bioreactors with Organoid Research

Integrating bioreactors with organoid culture enhances scalability and reproducibility in tissue engineering, enabling precise control of microenvironmental conditions such as oxygen tension, nutrient gradients, and mechanical stimuli. Advanced bioreactor systems facilitate long-term maintenance and maturation of complex organoids, improving their physiological relevance for drug screening and disease modeling. Future prospects include the development of automated, high-throughput bioreactor platforms to accelerate personalized medicine and regenerative therapies.

Related Important Terms

Microfluidic Bioreactors

Microfluidic bioreactors offer precise control over nutrient flow and waste removal, enhancing cell viability and differentiation compared to static organoid cultures. These systems enable high-throughput screening and mimic physiological microenvironments, improving scalability and reproducibility in tissue engineering research.

Organoid-on-a-Chip

Organoid-on-a-chip technology integrates microfluidic devices with three-dimensional organoid cultures, enhancing physiological relevance by enabling precise control over the cellular microenvironment and dynamic nutrient perfusion. This advanced platform surpasses traditional bioreactor systems by providing real-time monitoring, scalability, and improved mimicry of in vivo tissue architecture, which is crucial for drug screening and disease modeling.

Perfusion Bioreactors

Perfusion bioreactors provide continuous nutrient flow and waste removal, enhancing cell viability and mimicking physiological conditions more accurately than static organoid cultures. This dynamic environment promotes efficient mass transfer and shear stress regulation, crucial for the maturation and functional development of organoids in tissue engineering and disease modeling.

Matrigel Substitution

Bioreactor systems enhance cell proliferation and differentiation by providing controlled mechanical and biochemical environments, making them suitable for large-scale organoid culture without relying on Matrigel. Synthetic hydrogels and extracellular matrix mimetics serve as effective Matrigel substitutes, offering reproducible, tunable biochemical and mechanical properties critical for organoid growth within bioreactors.

Scaffold-Free Organoids

Scaffold-free organoid culture enables the self-assembly of cells into three-dimensional structures without the need for artificial support, closely mimicking in vivo tissue architecture and function. Bioreactors provide controlled environmental conditions, such as optimized nutrient diffusion and mechanical forces, enhancing organoid growth and viability for advanced tissue engineering applications.

Dynamic Culture Systems

Dynamic culture systems in bioreactors provide enhanced nutrient and oxygen exchange through continuous agitation or perfusion, promoting more uniform cell growth and maturation compared to static organoid cultures. These systems enable precise control of mechanical forces and microenvironmental conditions, improving physiological relevance and scalability in tissue engineering and regenerative medicine applications.

Synthetic ECM (Extracellular Matrix)

Synthetic extracellular matrices (ECMs) in bioreactor cultures provide tunable mechanical and biochemical properties, enhancing cell differentiation and tissue maturation compared to organoid cultures with natural ECMs. Engineered synthetic ECMs enable precise control over matrix stiffness, porosity, and ligand presentation, optimizing microenvironments for scalable, reproducible tissue development in bioreactors.

3D Printed Bioreactors

3D printed bioreactors enable precise control over microenvironmental parameters, enhancing cell proliferation and differentiation compared to traditional organoid cultures. These advanced bioreactors offer customizable scaffold architectures, improving nutrient diffusion and mechanical stimulation essential for 3D tissue modeling.

Self-Organizing Organoids

Self-organizing organoids exhibit complex tissue architecture and cellular differentiation resembling in vivo conditions, enabling more accurate modeling of organ development and disease processes compared to traditional bioreactor cultures. Bioreactors enhance organoid growth by providing controlled environments with dynamic nutrient flow and mechanical forces, optimizing organoid size and viability while preserving their intrinsic self-organizing capabilities.

Bioprinted Organoid Constructs

Bioprinted organoid constructs in bioreactor culture systems enable precise spatial control and enhanced nutrient perfusion, promoting more physiologically relevant tissue architecture and functional maturation compared to traditional static organoid cultures. Integration of microfluidic bioreactors facilitates dynamic mechanical cues and real-time monitoring, significantly improving organoid viability and scalability for drug screening and regenerative medicine applications.

Bioreactor vs Organoid Culture Infographic

industrydif.com

industrydif.com