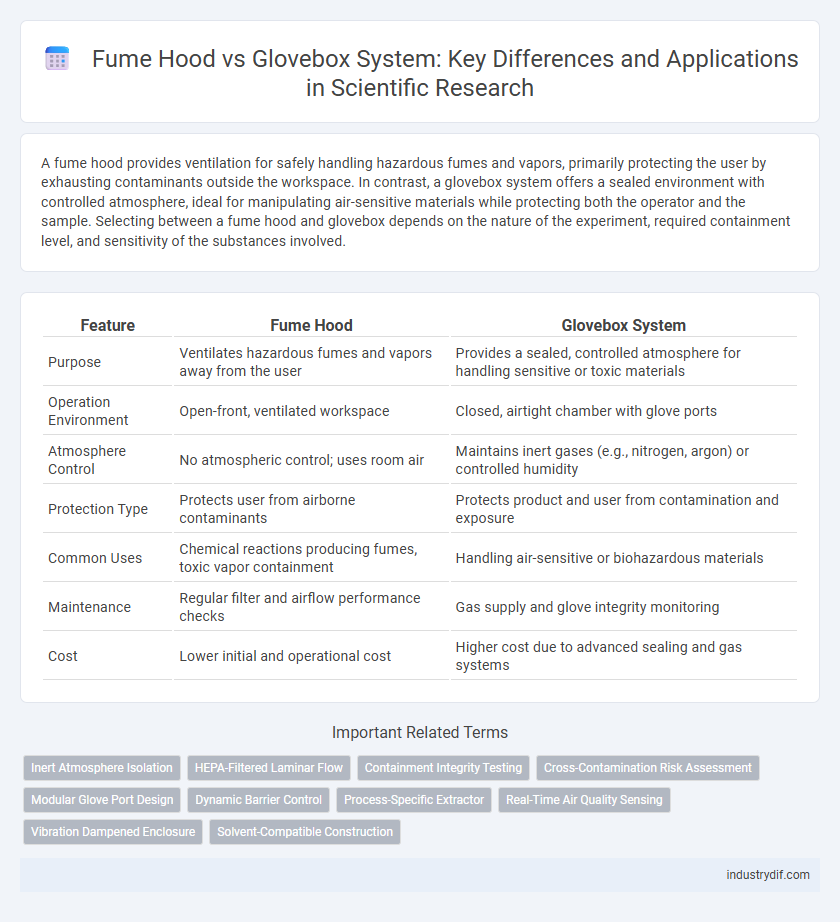

A fume hood provides ventilation for safely handling hazardous fumes and vapors, primarily protecting the user by exhausting contaminants outside the workspace. In contrast, a glovebox system offers a sealed environment with controlled atmosphere, ideal for manipulating air-sensitive materials while protecting both the operator and the sample. Selecting between a fume hood and glovebox depends on the nature of the experiment, required containment level, and sensitivity of the substances involved.

Table of Comparison

| Feature | Fume Hood | Glovebox System |

|---|---|---|

| Purpose | Ventilates hazardous fumes and vapors away from the user | Provides a sealed, controlled atmosphere for handling sensitive or toxic materials |

| Operation Environment | Open-front, ventilated workspace | Closed, airtight chamber with glove ports |

| Atmosphere Control | No atmospheric control; uses room air | Maintains inert gases (e.g., nitrogen, argon) or controlled humidity |

| Protection Type | Protects user from airborne contaminants | Protects product and user from contamination and exposure |

| Common Uses | Chemical reactions producing fumes, toxic vapor containment | Handling air-sensitive or biohazardous materials |

| Maintenance | Regular filter and airflow performance checks | Gas supply and glove integrity monitoring |

| Cost | Lower initial and operational cost | Higher cost due to advanced sealing and gas systems |

Introduction to Fume Hoods and Glovebox Systems

Fume hoods and glovebox systems serve as essential containment devices in scientific laboratories, designed to protect users from exposure to hazardous substances. Fume hoods primarily utilize airflow to capture and exhaust toxic fumes, vapors, and dust, ensuring a safe working environment. Glovebox systems offer a sealed environment with integrated gloves, allowing manipulation of sensitive or dangerous materials in an inert or controlled atmosphere.

Core Functionality: Fume Hood vs Glovebox

Fume hoods primarily function to protect users from hazardous airborne substances by ventilating toxic fumes out of the laboratory environment, maintaining a safe atmosphere through continuous airflow. Glovebox systems provide an enclosed workspace with a controlled atmosphere, allowing manipulation of substances in an inert or oxygen-free environment to prevent contamination or reaction. Both systems are essential for chemical safety but differ in containment methodology and application specificity.

Applications in Scientific Research

Fume hoods are primarily used for handling volatile chemicals and toxic fumes in chemical, pharmaceutical, and biological laboratories to ensure researcher safety and maintain air quality. Glovebox systems provide a controlled, inert atmosphere for manipulating air-sensitive materials or hazardous substances, essential in fields like nanotechnology, semiconductor research, and nuclear science. Both systems are critical for maintaining experimental integrity and protecting scientists when working with reactive, toxic, or sensitive compounds.

Containment and Protection Mechanisms

Fume hoods utilize airflow to capture and exhaust hazardous vapors, providing containment through negative pressure and filtration systems, ideal for volatile chemical handling. Glovebox systems offer a sealed environment with physical barriers and controlled atmospheres, ensuring protection against highly toxic, reactive, or sensitive substances by preventing direct contact and contamination. Both systems maintain containment, but gloveboxes excel in isolating materials within an inert or controlled atmosphere, whereas fume hoods prioritize ventilation and exposure reduction in open-lab workspaces.

Material Compatibility and Chemical Handling

Fume hoods provide effective ventilation for handling volatile organic solvents and acids, ensuring material compatibility with standard laboratory glass and metal components, but they offer limited protection against moisture-sensitive or pyrophoric substances. Glovebox systems maintain an inert atmosphere, typically filled with nitrogen or argon, making them essential for manipulating air- and moisture-sensitive chemicals, while their interior materials are specially selected to resist corrosion from reactive agents. The choice between fume hood and glovebox hinges on the chemical's reactivity profile and compatibility with construction materials, optimizing safety and experimental integrity.

Safety Standards and Regulatory Compliance

Fume hoods and glovebox systems both adhere to stringent safety standards such as OSHA and ANSI/AIHA Z9.5 to ensure operator protection from hazardous substances. Fume hoods provide effective containment for volatile chemicals through ventilation, meeting EPA and NFPA regulations, while gloveboxes offer an inert atmosphere for handling highly sensitive materials, complying with ISO Class 5 standards. Regulatory compliance mandates routine performance testing and certification to maintain airtight integrity in gloveboxes and proper airflow velocity in fume hoods, crucial for minimizing exposure risks in scientific laboratories.

Installation and Maintenance Requirements

Fume hoods require straightforward installation involving ventilation ductwork to expel hazardous fumes, demanding regular filter replacements and airflow inspections for optimal safety performance. Glovebox systems necessitate complex sealing mechanisms and inert gas supply integration, with maintenance focusing on maintaining airtight seals and gas purity to prevent contamination. Both systems require routine calibration and component checks, but gloveboxes generally involve higher installation complexity and specialized maintenance due to their controlled atmosphere environment.

Cost Analysis and Operational Expenses

Fume hoods generally have lower initial costs compared to glovebox systems, with prices ranging from $3,000 to $10,000, whereas gloveboxes can cost between $15,000 and $50,000 due to their specialized containment features. Operational expenses for fume hoods include regular filter replacements and ventilation energy consumption, averaging around $500 to $1,000 annually, while gloveboxes incur higher maintenance costs linked to inert gas supply and glove replacement, often exceeding $2,000 per year. Long-term cost efficiency depends on laboratory requirements for containment, with gloveboxes offering superior protection for sensitive materials at the expense of increased operational expenditures.

User Accessibility and Ergonomics

Fume hoods provide greater user accessibility with open-front designs allowing easy access and quick material handling, supporting a wide range of experimental procedures. Glovebox systems, while limiting direct access, offer enhanced ergonomics by isolating hazardous environments and reducing operator exposure to toxic or sensitive substances. The choice between fume hoods and gloveboxes depends on balancing open access convenience with the necessity for controlled, ergonomic containment.

Choosing the Right System for Your Laboratory

Selecting between a fume hood and a glovebox system depends on the required containment level and the specific hazards of the laboratory materials. Fume hoods provide effective ventilation for volatile chemicals, protecting users from airborne contaminants, while glovebox systems offer an isolated environment for handling sensitive or hazardous substances under controlled atmospheres. Evaluating factors such as chemical reactivity, operator exposure risk, and experimental conditions ensures optimal safety and operational efficiency in laboratory settings.

Related Important Terms

Inert Atmosphere Isolation

Fume hoods provide ventilation to remove hazardous fumes but do not offer an inert atmosphere, making them unsuitable for moisture- or oxygen-sensitive experiments. Glovebox systems create a sealed environment filled with inert gases like nitrogen or argon, ensuring complete isolation from atmospheric contaminants for sensitive chemical reactions and material handling.

HEPA-Filtered Laminar Flow

HEPA-filtered laminar flow systems in fume hoods provide vertical airflow that protects both the operator and the environment by filtering out hazardous particulates, while glovebox systems utilize sealed environments with HEPA filtration to maintain an inert atmosphere and prevent contamination of sensitive materials. The choice between these systems depends on the need for containment of hazardous substances versus preservation of sample integrity in controlled atmospheres.

Containment Integrity Testing

Containment integrity testing for fume hoods involves evaluating airflow patterns and filter efficiency to prevent hazardous exposure, while glovebox systems require rigorous leak testing and pressure decay analysis to ensure complete isolation of toxic or sensitive materials. Both methods prioritize maintaining sealed environments, but glovebox systems demand higher precision due to their use in handling highly reactive or biohazardous substances.

Cross-Contamination Risk Assessment

Fume hoods primarily protect users by exhausting hazardous fumes but offer limited containment, increasing the risk of cross-contamination compared to glovebox systems, which provide a sealed environment with controlled internal atmosphere to significantly reduce contamination risks. Evaluating cross-contamination in laboratory settings requires assessing airflow patterns, barrier integrity, and operational protocols, with gloveboxes demonstrating superior performance in preventing particulate and microbial transfer during sensitive experimental procedures.

Modular Glove Port Design

Modular glove port design in glovebox systems enhances flexibility and customization, allowing precise control over containment and user access to hazardous materials compared to traditional fume hoods. These ports improve ergonomic efficiency, reduce exposure risks, and support complex scientific workflows by integrating interchangeable, airtight gloves tailored to specific experimental needs.

Dynamic Barrier Control

Dynamic barrier control in fume hoods ensures continuous airflow regulation to prevent hazardous fumes from escaping, optimizing user safety and containment efficiency. In contrast, glovebox systems maintain inert atmospheres through sealed environments with controlled pressure differentials, providing superior protection for highly sensitive or reactive substances.

Process-Specific Extractor

Process-specific extractors in fume hood systems provide targeted ventilation designed to capture hazardous fumes directly at the source, ensuring efficient removal of toxic vapors during chemical processes. In contrast, glovebox systems maintain a sealed environment with integrated extraction mechanisms, offering superior containment and controlled atmospheres for handling highly sensitive or reactive substances.

Real-Time Air Quality Sensing

Fume hoods primarily rely on airflow to contain hazardous fumes, but their real-time air quality sensing capabilities are often limited and typically focus on airflow velocity rather than contaminant concentration. Glovebox systems, equipped with advanced sensors such as gas detectors and particulate monitors, provide continuous real-time detection and control of specific toxic or reactive substances, ensuring a more precise and responsive environment for hazardous material handling.

Vibration Dampened Enclosure

Vibration dampened enclosures in fume hoods minimize mechanical disturbances, enhancing precision in sensitive scientific experiments by stabilizing airflow and reducing noise interference. In contrast, glovebox systems integrate vibration control within sealed environments, enabling contamination-free manipulation of hazardous materials while maintaining structural integrity against external vibrations.

Solvent-Compatible Construction

Fume hoods constructed with solvent-resistant materials such as polypropylene or fluoropolymers provide effective containment for volatile organic solvents, minimizing chemical degradation and ensuring operator safety in laboratory settings. In contrast, glovebox systems designed with solvent-compatible seals and coatings offer superior airtight environments for handling sensitive compounds, preventing solvent permeation and contamination during critical experimental procedures.

Fume Hood vs Glovebox System Infographic

industrydif.com

industrydif.com