Warehousing involves storing large quantities of goods in centralized facilities, optimized for bulk inventory management and long-term storage, while micro-fulfillment centers focus on rapid order processing near urban areas to enable faster delivery times. Micro-fulfillment integrates advanced automation and robotics to handle smaller, more frequent orders, reducing last-mile delivery costs and enhancing customer satisfaction. Choosing between warehousing and micro-fulfillment depends on the company's distribution strategy, inventory velocity, and demand patterns.

Table of Comparison

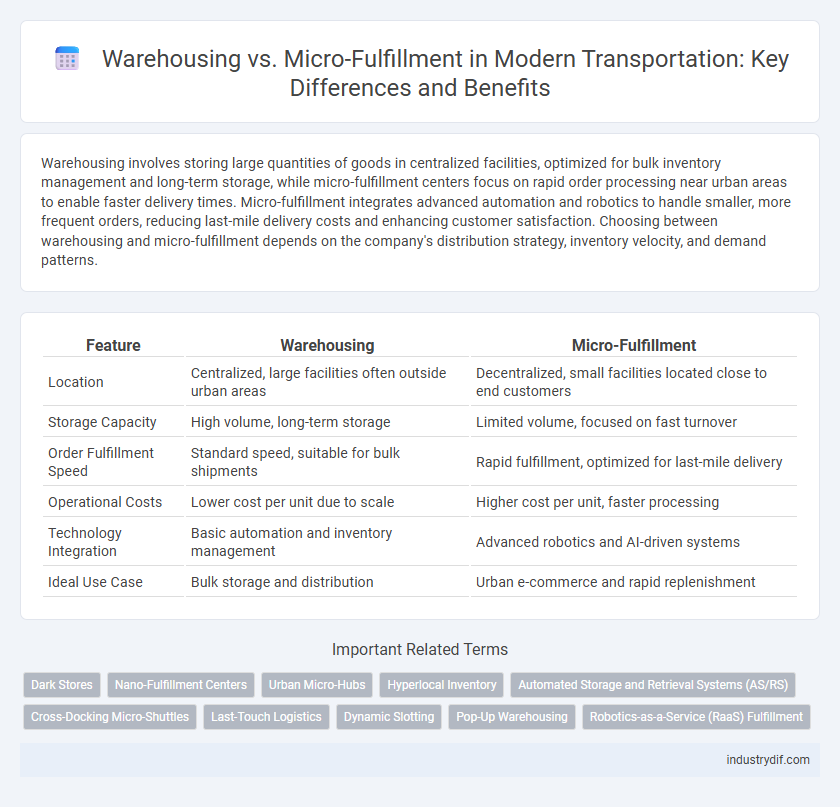

| Feature | Warehousing | Micro-Fulfillment |

|---|---|---|

| Location | Centralized, large facilities often outside urban areas | Decentralized, small facilities located close to end customers |

| Storage Capacity | High volume, long-term storage | Limited volume, focused on fast turnover |

| Order Fulfillment Speed | Standard speed, suitable for bulk shipments | Rapid fulfillment, optimized for last-mile delivery |

| Operational Costs | Lower cost per unit due to scale | Higher cost per unit, faster processing |

| Technology Integration | Basic automation and inventory management | Advanced robotics and AI-driven systems |

| Ideal Use Case | Bulk storage and distribution | Urban e-commerce and rapid replenishment |

Defining Warehousing and Micro-Fulfillment

Warehousing involves the large-scale storage of goods in centralized facilities designed to hold inventory for extended periods, supporting bulk inventory management and distribution. Micro-fulfillment refers to localized, technology-driven fulfillment centers situated closer to the end consumer, optimizing rapid order processing and last-mile delivery efficiency. These micro-fulfillment centers leverage automation and real-time inventory tracking to enhance speed and reduce transportation costs in urban retail environments.

Key Differences Between Warehousing and Micro-Fulfillment

Warehousing involves large storage facilities that hold extensive inventory for long-term distribution, while micro-fulfillment centers are smaller, strategically located facilities designed for rapid order processing and last-mile delivery. Warehousing focuses on bulk storage with slower inventory turnover, whereas micro-fulfillment emphasizes speed, automation, and proximity to urban consumers to meet immediate demand. The key differences lie in scale, location, inventory management, and fulfillment speed, impacting supply chain efficiency and customer satisfaction in transportation logistics.

Space Requirements and Facility Design

Warehousing typically requires expansive space with high ceilings to accommodate bulk storage, large inventory volumes, and long-term goods holding, emphasizing efficient aisle design and heavy equipment access. Micro-fulfillment centers prioritize compact, modular layouts that optimize space for rapid order processing and inventory turnover, often integrating automation and robotics to maximize vertical and horizontal space utilization. Facility design for micro-fulfillment focuses on proximity to end consumers within urban areas, reducing delivery times while warehouses are usually located in industrial zones to balance space availability and cost.

Automation and Technology Integration

Warehousing and micro-fulfillment both leverage automation and technology integration to enhance efficiency, yet micro-fulfillment centers employ advanced robotics and AI-driven systems for rapid, small-batch order processing closer to urban consumers. Traditional warehouses prioritize large-scale storage automation with conveyor belts, warehouse management systems (WMS), and automated guided vehicles (AGVs) optimized for bulk inventory management. The integration of IoT sensors and real-time data analytics in micro-fulfillment centers enables precise inventory tracking and faster order turnaround, catering to the rising demand for same-day delivery.

Order Processing Speeds and Efficiency

Micro-fulfillment centers drastically improve order processing speeds by leveraging automation and proximity to end consumers, reducing delivery times from days to mere hours. Traditional warehousing, while capable of handling larger inventory volumes, often involves longer picking and packing cycles due to centralized locations and manual processes. Optimizing efficiency in micro-fulfillment relies on advanced robotics and real-time inventory management, whereas warehouses prioritize space utilization and bulk storage economies.

Cost Structures and Investment Considerations

Warehousing typically involves higher fixed costs due to large storage spaces and long-term leases, while micro-fulfillment centers require significant upfront investment in automation technology but benefit from lower operational expenses. Micro-fulfillment systems optimize last-mile delivery by reducing transportation costs and improving order accuracy, offering faster inventory turnover compared to traditional warehousing. Businesses must weigh capital expenditure against scalability, with warehousing favoring bulk storage for extended periods and micro-fulfillment emphasizing speed and proximity to end customers.

Scalability and Flexibility in Operations

Warehousing offers high scalability with large storage capacities ideal for bulk inventory management, yet it often lacks the agility needed for rapid order fulfillment. Micro-fulfillment centers provide greater operational flexibility by enabling faster processing times and localized distribution, accommodating fluctuating demand patterns efficiently. Businesses leverage micro-fulfillment to optimize last-mile delivery, improving customer satisfaction while scaling operations through modular, technology-driven solutions.

Impact on Last-Mile Delivery

Warehousing centers typically store large inventories, enabling bulk shipping but often resulting in longer last-mile delivery times due to centralized locations. Micro-fulfillment centers, positioned closer to urban areas, reduce delivery distances and improve speed and efficiency for last-mile delivery. The impact on last-mile transportation includes lower costs, enhanced customer satisfaction through faster delivery, and reduced environmental footprint with micro-fulfillment compared to traditional warehousing.

Suitability for E-commerce and Retail Sectors

Warehousing offers extensive storage capacity ideal for bulk inventory in traditional retail, while micro-fulfillment centers provide rapid, localized order processing tailored to e-commerce demands. Micro-fulfillment enhances last-mile delivery efficiency and reduces fulfillment time, making it especially suitable for high-velocity e-commerce operations. Retailers balancing large product assortments with fast delivery often integrate both systems to optimize supply chain responsiveness and customer satisfaction.

Future Trends in Warehousing and Micro-Fulfillment

Emerging trends in warehousing and micro-fulfillment emphasize the integration of advanced automation technologies such as robotics, AI-driven inventory management, and IoT-enabled real-time tracking to enhance operational efficiency and reduce fulfillment times. The growing demand for rapid, last-mile delivery in e-commerce is driving the expansion of micro-fulfillment centers located closer to urban consumers, enabling higher order accuracy and reduced logistics costs. Sustainability initiatives are also shaping future developments, with warehouses adopting energy-efficient systems and micro-fulfillment processes minimizing carbon footprints through optimized local distribution networks.

Related Important Terms

Dark Stores

Dark stores operate as streamlined fulfillment centers designed specifically for rapid e-commerce order processing, contrasting traditional warehousing by emphasizing speed and proximity to urban consumers. Micro-fulfillment leverages automated systems within these dark stores to optimize inventory management and reduce last-mile delivery times, enhancing overall supply chain efficiency.

Nano-Fulfillment Centers

Nano-fulfillment centers, significantly smaller than traditional warehousing and micro-fulfillment setups, optimize last-mile delivery by enabling real-time inventory management within urban environments. These compact facilities leverage AI-driven automation to reduce transportation costs, enhance delivery speed, and support omnichannel retail strategies.

Urban Micro-Hubs

Urban micro-hubs leverage micro-fulfillment centers to reduce last-mile delivery times by strategically positioning inventory closer to consumers, enhancing efficiency in densely populated areas. Warehousing typically involves larger, centralized facilities focused on bulk storage, whereas micro-fulfillment centers emphasize speed and agility to meet immediate urban demand.

Hyperlocal Inventory

Hyperlocal inventory strategies prioritize micro-fulfillment centers over traditional warehousing by enabling faster delivery and reducing last-mile transportation costs. Micro-fulfillment hubs located near end consumers optimize inventory availability and improve order accuracy, driving efficiency in urban supply chains.

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) in warehousing enhance capacity and accuracy by utilizing large-scale robotic systems for bulk storage and retrieval, ideal for traditional distribution centers. In contrast, micro-fulfillment centers integrate compact AS/RS technologies to accelerate order processing in urban locations, optimizing last-mile delivery efficiency and reducing labor costs.

Cross-Docking Micro-Shuttles

Cross-docking micro-shuttles streamline inventory flow by rapidly transferring goods from inbound to outbound transportation without long-term storage, enhancing efficiency in distribution centers. This automation reduces handling time and labor costs compared to traditional warehousing methods, optimizing space utilization and accelerating order fulfillment cycles.

Last-Touch Logistics

Warehousing traditionally involves large-scale storage facilities managing inventory over longer durations, while micro-fulfillment centers optimize last-touch logistics by enabling rapid, localized order processing close to end consumers. This shift enhances delivery speed and reduces transportation costs by minimizing distance and handling stages in the last mile.

Dynamic Slotting

Dynamic slotting in warehousing optimizes storage locations based on real-time demand and inventory flows, improving picking efficiency and reducing travel time for workers. In micro-fulfillment centers, dynamic slotting enhances rapid order processing by continuously adapting slot assignments to high-turnover, small-batch inventories, driving faster delivery in urban settings.

Pop-Up Warehousing

Pop-up warehousing enhances micro-fulfillment by providing flexible, temporary storage solutions closer to end customers, reducing last-mile delivery times and operational costs. This approach leverages underutilized urban spaces to support rapid order fulfillment and adapt to fluctuating demand without the need for permanent large-scale warehouses.

Robotics-as-a-Service (RaaS) Fulfillment

Robotics-as-a-Service (RaaS) transforms warehousing by enabling scalable, automated fulfillment solutions that reduce labor costs and increase efficiency. Micro-fulfillment centers leverage RaaS to optimize rapid order processing within urban areas, enhancing last-mile delivery speed and accuracy.

Warehousing vs Micro-Fulfillment Infographic

industrydif.com

industrydif.com