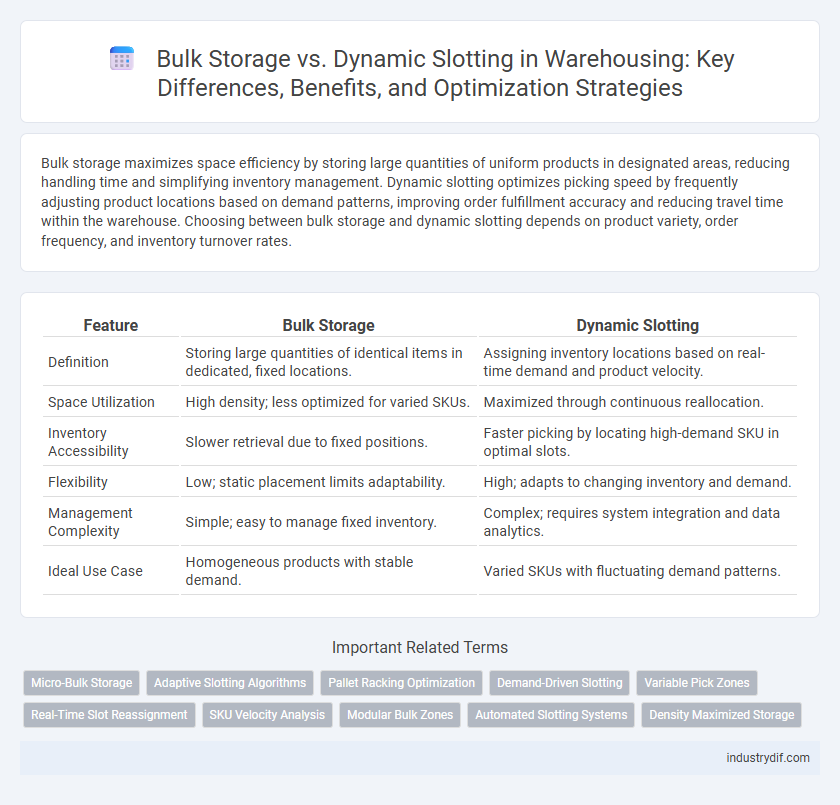

Bulk storage maximizes space efficiency by storing large quantities of uniform products in designated areas, reducing handling time and simplifying inventory management. Dynamic slotting optimizes picking speed by frequently adjusting product locations based on demand patterns, improving order fulfillment accuracy and reducing travel time within the warehouse. Choosing between bulk storage and dynamic slotting depends on product variety, order frequency, and inventory turnover rates.

Table of Comparison

| Feature | Bulk Storage | Dynamic Slotting |

|---|---|---|

| Definition | Storing large quantities of identical items in dedicated, fixed locations. | Assigning inventory locations based on real-time demand and product velocity. |

| Space Utilization | High density; less optimized for varied SKUs. | Maximized through continuous reallocation. |

| Inventory Accessibility | Slower retrieval due to fixed positions. | Faster picking by locating high-demand SKU in optimal slots. |

| Flexibility | Low; static placement limits adaptability. | High; adapts to changing inventory and demand. |

| Management Complexity | Simple; easy to manage fixed inventory. | Complex; requires system integration and data analytics. |

| Ideal Use Case | Homogeneous products with stable demand. | Varied SKUs with fluctuating demand patterns. |

Understanding Bulk Storage in Warehousing

Bulk storage in warehousing involves storing large quantities of homogeneous products without assigned locations, maximizing space utilization by stacking items directly on the floor or pallets. This method simplifies inventory management by reducing the need for constant relocation and is ideal for products with low SKU variety and high volume. Efficient bulk storage relies on accurate demand forecasting and robust inventory tracking systems to prevent overstocking and ensure quick retrieval.

What is Dynamic Slotting?

Dynamic slotting optimizes warehouse efficiency by continuously analyzing order patterns and inventory turnover to assign the most suitable storage locations. Unlike bulk storage, which stores large quantities of products in fixed areas, dynamic slotting adapts storage positions based on real-time data, reducing picking times and improving space utilization. This method leverages automated systems and analytics to enhance inventory accuracy and streamline warehouse operations.

Key Differences Between Bulk Storage and Dynamic Slotting

Bulk storage involves storing large quantities of homogeneous products in fixed locations, optimizing space utilization but often requiring more time for picking and retrieval. Dynamic slotting continuously adjusts product locations based on demand patterns and inventory changes, improving picking efficiency and reducing travel time. Key differences include static placement in bulk storage versus flexible, data-driven organization in dynamic slotting that enhances order accuracy and warehouse throughput.

Advantages of Bulk Storage Systems

Bulk storage systems maximize warehouse space by storing large quantities of homogeneous products in a single location, enhancing inventory density and reducing handling costs. These systems simplify inventory management due to the reduced need for frequent slot changes and allow for faster loading and unloading processes. High storage efficiency and lower infrastructure investment make bulk storage an economical solution for warehouses dealing with uniform product lines.

Benefits of Implementing Dynamic Slotting

Dynamic slotting in warehousing enhances space utilization by continuously optimizing product placement based on real-time demand patterns, reducing travel time and increasing picking efficiency. It improves inventory accuracy and adaptability, accommodating seasonal fluctuations and product lifecycle changes more effectively than static bulk storage. This method supports faster order fulfillment and lowers labor costs, driving overall operational productivity.

Space Utilization: Bulk Storage vs Dynamic Slotting

Bulk storage maximizes space utilization by stacking large quantities of homogeneous products in a fixed, dense area, reducing aisle space but limiting accessibility. Dynamic slotting enhances space efficiency by continuously reorganizing inventory based on demand patterns, improving picking speed and reducing wasted space from static layouts. Warehouses using dynamic slotting typically achieve higher overall space optimization and operational flexibility compared to bulk storage systems.

Operational Efficiency Comparison

Bulk storage maximizes space utilization by consolidating goods in large, static locations, resulting in simplified inventory management but slower access times. Dynamic slotting improves operational efficiency by continuously optimizing item placement based on demand patterns, reducing pick times and labor costs. Warehouses using dynamic slotting report up to 30% faster order fulfillment compared to those relying solely on bulk storage systems.

Inventory Management: Static vs Dynamic Approaches

Bulk storage relies on static inventory management, grouping large quantities of similar items together for efficient space utilization but limited flexibility. Dynamic slotting adapts storage locations based on real-time data and demand patterns, optimizing picking efficiency and reducing travel time. Combining bulk storage with dynamic slotting improves warehouse throughput by balancing space optimization and rapid inventory access.

Choosing the Right Method for Your Warehouse

Bulk storage maximizes space by storing products in large quantities without individual pick locations, ideal for high-volume, low-SKU warehouses. Dynamic slotting optimizes picking efficiency through data-driven placement of items based on demand patterns and product velocity, suitable for warehouses with diverse inventories and fluctuating order profiles. Selecting the right method involves analyzing inventory characteristics, order frequency, and warehouse layout to balance storage density and retrieval speed effectively.

Future Trends in Bulk Storage and Dynamic Slotting

Future trends in bulk storage emphasize automation and IoT integration to enhance inventory accuracy and space utilization. Dynamic slotting is evolving with AI-driven algorithms that optimize product placement based on real-time demand forecasting and picking frequency. These advancements collectively improve warehouse efficiency, reduce operational costs, and enable scalable storage solutions.

Related Important Terms

Micro-Bulk Storage

Micro-bulk storage optimizes warehouse efficiency by combining the high-density capacity of bulk storage with the flexibility of dynamic slotting, enabling precise inventory control and faster retrieval of small, frequently accessed items. This hybrid approach reduces space utilization while improving stock rotation and accuracy in order fulfillment.

Adaptive Slotting Algorithms

Adaptive slotting algorithms optimize warehouse efficiency by continuously analyzing inventory turnover rates and product demand patterns to dynamically adjust bulk storage locations. This approach reduces picking times and maximizes space utilization compared to static bulk storage methods, leading to improved order fulfillment accuracy and faster inventory access.

Pallet Racking Optimization

Bulk storage maximizes space by stacking pallets in large quantities but limits accessibility and picking efficiency, whereas dynamic slotting enhances pallet racking optimization by continuously adjusting slot assignments based on demand patterns, reducing travel time and increasing throughput. Implementing dynamic slotting leverages real-time data analytics to improve warehouse layout utilization and boost inventory turnover rates effectively.

Demand-Driven Slotting

Demand-driven slotting optimizes warehouse efficiency by dynamically assigning inventory locations based on real-time demand and picking frequency, unlike bulk storage which groups items primarily by quantity and size. This approach reduces travel time and improves order accuracy, enabling faster fulfillment and better space utilization in high-velocity warehouses.

Variable Pick Zones

Bulk storage optimizes space by consolidating high-volume items in dedicated areas, while dynamic slotting enhances efficiency by frequently adjusting pick locations based on demand variability and item velocity. Implementing variable pick zones allows warehouses to respond swiftly to changing order patterns, improving picker productivity and reducing travel time.

Real-Time Slot Reassignment

Real-time slot reassignment in warehousing enhances inventory management by dynamically adjusting storage locations based on current demand and product velocity, reducing retrieval times and increasing picking efficiency. Unlike static bulk storage, dynamic slotting leverages real-time data analytics to optimize space utilization and streamline workflows, resulting in improved operational agility and reduced labor costs.

SKU Velocity Analysis

SKU velocity analysis is essential for optimizing warehouse efficiency by determining whether bulk storage or dynamic slotting best suits product movement patterns. High-velocity SKUs benefit from dynamic slotting through frequent repositioning closer to pick faces, while low-velocity SKUs are more cost-effectively stored in bulk storage zones with less retrieval urgency.

Modular Bulk Zones

Modular Bulk Zones in warehousing optimize space utilization by combining the high-density storage capabilities of Bulk Storage with the flexibility of Dynamic Slotting, enabling efficient handling of varying SKU sizes and turnover rates. This hybrid approach enhances inventory accuracy and picking speed by segmenting bulk items into adjustable zones tailored to real-time demand and operational workflows.

Automated Slotting Systems

Automated slotting systems enhance warehouse efficiency by using dynamic slotting methods that adjust product placement based on real-time data and demand patterns, unlike bulk storage which relies on static, large-volume storage with limited accessibility. This technology improves inventory accuracy and picking speed, optimizing space utilization and reducing labor costs through intelligent, data-driven product allocation.

Density Maximized Storage

Bulk storage utilizes large, contiguous areas to maximize space density by stacking uniform products, enabling high-volume inventory retention with minimal aisle space. Dynamic slotting optimizes storage density by continuously adjusting product locations based on real-time demand and size data, enhancing space utilization and operational efficiency in high-turnover warehouses.

Bulk Storage vs Dynamic Slotting Infographic

industrydif.com

industrydif.com