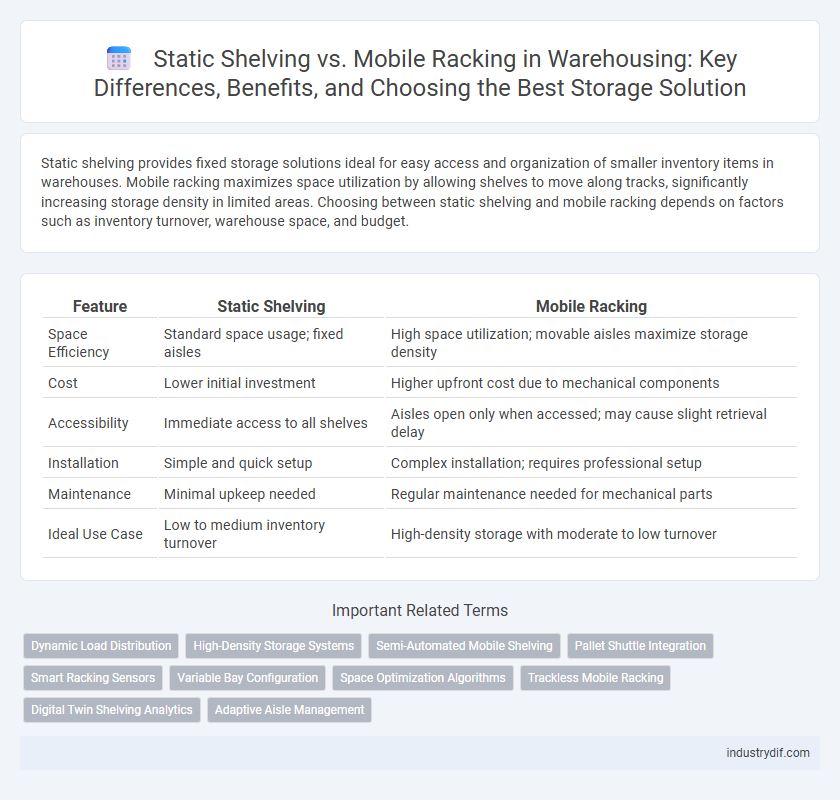

Static shelving provides fixed storage solutions ideal for easy access and organization of smaller inventory items in warehouses. Mobile racking maximizes space utilization by allowing shelves to move along tracks, significantly increasing storage density in limited areas. Choosing between static shelving and mobile racking depends on factors such as inventory turnover, warehouse space, and budget.

Table of Comparison

| Feature | Static Shelving | Mobile Racking |

|---|---|---|

| Space Efficiency | Standard space usage; fixed aisles | High space utilization; movable aisles maximize storage density |

| Cost | Lower initial investment | Higher upfront cost due to mechanical components |

| Accessibility | Immediate access to all shelves | Aisles open only when accessed; may cause slight retrieval delay |

| Installation | Simple and quick setup | Complex installation; requires professional setup |

| Maintenance | Minimal upkeep needed | Regular maintenance needed for mechanical parts |

| Ideal Use Case | Low to medium inventory turnover | High-density storage with moderate to low turnover |

Introduction to Static Shelving and Mobile Racking

Static shelving offers a fixed storage solution ideal for organizing goods with easy accessibility and straightforward installation, making it suitable for warehouses with consistent inventory layouts. Mobile racking systems maximize storage density by enabling racks to move on tracks, reducing aisle space and increasing capacity without expanding the warehouse footprint. Both options cater to different operational needs, with static shelving favoring simplicity and mobile racking emphasizing space efficiency.

Key Differences Between Static and Mobile Storage Solutions

Static shelving provides fixed, stationary storage with easy access but requires more floor space, making it ideal for warehouses with lower space constraints. Mobile racking maximizes storage density by mounting shelving units on tracks that move to create an aisle only when needed, significantly increasing storage capacity in limited areas. While static shelves offer simpler installation and maintenance, mobile racking demands higher upfront investment and mechanical upkeep but delivers superior space efficiency and improved inventory management.

Space Utilization: Maximizing Warehouse Capacity

Static shelving offers straightforward organization but generally consumes more floor space, limiting warehouse capacity efficiency. Mobile racking systems enable aisles to be compacted and expanded only when needed, significantly increasing storage density and maximizing space utilization. Implementing mobile racking can boost warehouse capacity by up to 80% compared to traditional static shelving setups.

Cost Implications: Initial Investment and Long-Term ROI

Static shelving requires lower initial investment due to simpler installation and minimal structural modifications, making it suitable for limited budgets. Mobile racking demands higher upfront costs because of mechanical systems and reinforced flooring but maximizes space, increasing storage density and improving long-term ROI. Evaluating warehouse size and inventory turnover is critical to determining which system delivers better cost efficiency over time.

Installation and Maintenance Requirements

Static shelving requires minimal installation, involving simple assembly and fixed placement, which results in lower initial setup time and maintenance needs. Mobile racking demands precise installation with tracks and motorized systems, increasing both complexity and the frequency of maintenance to ensure smooth operation. Proper maintenance of mobile systems is critical to prevent breakdowns, while static shelving primarily requires routine inspections for stability and cleanliness.

Flexibility and Adaptability for Changing Inventory

Static shelving offers a fixed structure ideal for consistent inventory but lacks flexibility for fluctuating stock volumes. Mobile racking maximizes storage density by enabling aisles to open only where needed, adapting quickly to changes in inventory size and type. This adaptability ensures efficient space utilization and streamlined access in dynamic warehousing environments.

Safety Considerations and Risk Management

Static shelving offers stable storage with minimal mechanical parts, reducing the risk of malfunctions and accidents, while mobile racking maximizes space but requires rigorous safety protocols to prevent accidents during movement. Safety measures for mobile racking include regular maintenance, safety sensors, and operator training to manage risks such as entrapment or structural failure. Effective risk management involves assessing load capacity limits and implementing emergency stop mechanisms tailored to each storage system type.

Accessibility and Picking Efficiency

Static shelving offers fixed access points, allowing easy visibility but limiting aisle width and slowing picking speed in high-density storage. Mobile racking systems maximize space by eliminating multiple aisles, creating a single movable aisle that enhances picking efficiency and accessibility in compact warehouses. Optimizing warehouse layout with mobile racking improves order fulfillment rates by reducing travel time and streamlining pick paths.

Suitable Applications for Various Industries

Static shelving is ideal for industries requiring easy access to smaller quantities of inventory, such as retail, pharmaceuticals, and libraries, where organization and visibility are paramount. Mobile racking excels in warehouses with limited floor space, like automotive, aerospace, and cold storage facilities, offering high-density storage by compacting aisles and maximizing cubic storage capacity. Each system aligns with specific operational needs--static shelving supports quick picking and product rotation, while mobile racking optimizes space efficiency and inventory volume management.

Choosing the Right System for Your Warehouse Needs

Choosing the right warehouse storage system depends on space optimization and accessibility requirements. Static shelving offers durability and easy item retrieval for warehouses with ample floor space, while mobile racking maximizes storage capacity by eliminating aisles through movable units, ideal for limited space environments. Assess inventory turnover rates and aisle access frequency to determine which solution improves operational efficiency and reduces retrieval times effectively.

Related Important Terms

Dynamic Load Distribution

Static shelving offers fixed storage compartments that provide stable, consistent load-bearing capacity ideal for light to moderate storage needs, while mobile racking systems utilize compacted units on tracks to optimize space and dynamically distribute heavy loads across multiple support points, enhancing structural integrity and maximizing warehouse floor utilization. Dynamic load distribution in mobile racking reduces floor pressure and wear, making it suitable for high-density storage environments requiring frequent access and reconfiguration.

High-Density Storage Systems

High-density storage systems such as mobile racking increase warehouse capacity by utilizing movable shelves on tracks, reducing aisle space compared to static shelving that requires fixed aisles. Mobile racking offers greater storage density and improved space efficiency, making it ideal for facilities with limited floor area or high inventory turnover demands.

Semi-Automated Mobile Shelving

Semi-automated mobile shelving enhances warehouse storage efficiency by combining the compactness of mobile racking with automated retrieval systems, optimizing space utilization up to 85% more than traditional static shelving. This technology reduces manual labor while increasing picking speed and accuracy, making it ideal for high-density storage environments requiring frequent access to inventory.

Pallet Shuttle Integration

Static shelving offers fixed storage locations ideal for easy access but limits space utilization, whereas mobile racking maximizes warehouse density by eliminating aisles; integrating pallet shuttle systems enhances mobile racking efficiency by automating pallet movement, reducing retrieval time and labor costs. Pallet shuttle technology seamlessly combines with mobile racking to optimize high-volume pallet handling, improving warehouse throughput and storage flexibility in distribution centers.

Smart Racking Sensors

Smart racking sensors integrated into mobile racking systems dramatically enhance inventory accuracy and space utilization by providing real-time data on stock levels and movement patterns. Unlike static shelving, these sensors enable dynamic storage optimization and predictive maintenance, reducing downtime and improving overall warehouse efficiency.

Variable Bay Configuration

Static shelving offers fixed bay configurations ideal for consistent inventory sizes, whereas mobile racking provides adjustable bay spacing that maximizes storage density by accommodating variable item dimensions and optimizing aisle widths for dynamic warehouse layouts. Variable bay configuration in mobile racking enables enhanced space utilization and increased accessibility, crucial for warehouses managing diverse stock keeping units (SKUs).

Space Optimization Algorithms

Static shelving offers straightforward organization but limits space utilization by requiring fixed aisles, whereas mobile racking maximizes storage density through compact aisle systems driven by advanced space optimization algorithms that dynamically allocate access points. Algorithms analyze inventory turnover and retrieval patterns to adjust aisle positions, significantly enhancing warehouse capacity and operational efficiency.

Trackless Mobile Racking

Trackless Mobile Racking systems optimize warehouse space by eliminating fixed aisles, allowing shelves to move independently on motorized bases and significantly increasing storage density compared to static shelving. This innovative solution enhances operational efficiency by providing flexible access to inventory while maximizing floor space utilization without the need for fixed tracks.

Digital Twin Shelving Analytics

Digital Twin Shelving Analytics enhances both Static Shelving and Mobile Racking by providing real-time inventory tracking, optimizing space utilization, and predicting maintenance needs through precise digital replicas of physical storage systems. This advanced technology enables dynamic configuration adjustments and performance monitoring, significantly improving warehouse efficiency and cost management.

Adaptive Aisle Management

Static shelving offers fixed aisle widths, limiting space utilization and flexibility, while mobile racking systems enable adaptive aisle management by allowing aisles to open only where needed, significantly increasing storage density. This dynamic control of aisle accessibility optimizes warehouse footprint, reduces travel time for picking operations, and enhances overall inventory management efficiency.

Static Shelving vs Mobile Racking Infographic

industrydif.com

industrydif.com