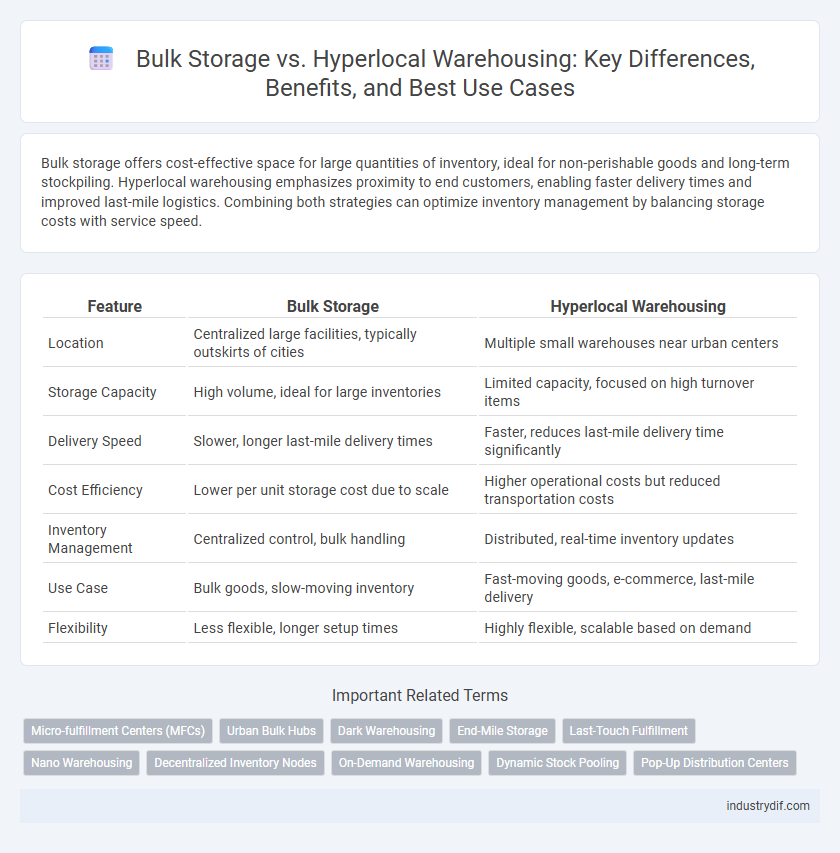

Bulk storage offers cost-effective space for large quantities of inventory, ideal for non-perishable goods and long-term stockpiling. Hyperlocal warehousing emphasizes proximity to end customers, enabling faster delivery times and improved last-mile logistics. Combining both strategies can optimize inventory management by balancing storage costs with service speed.

Table of Comparison

| Feature | Bulk Storage | Hyperlocal Warehousing |

|---|---|---|

| Location | Centralized large facilities, typically outskirts of cities | Multiple small warehouses near urban centers |

| Storage Capacity | High volume, ideal for large inventories | Limited capacity, focused on high turnover items |

| Delivery Speed | Slower, longer last-mile delivery times | Faster, reduces last-mile delivery time significantly |

| Cost Efficiency | Lower per unit storage cost due to scale | Higher operational costs but reduced transportation costs |

| Inventory Management | Centralized control, bulk handling | Distributed, real-time inventory updates |

| Use Case | Bulk goods, slow-moving inventory | Fast-moving goods, e-commerce, last-mile delivery |

| Flexibility | Less flexible, longer setup times | Highly flexible, scalable based on demand |

Defining Bulk Storage

Bulk storage involves consolidating large quantities of goods in centralized warehouses, optimizing inventory management for high-volume products. This method reduces handling costs and simplifies supply chain logistics by storing items in palletized or loose bulk form. Bulk storage suits industries with steady demand and extensive space requirements, contrasting with hyperlocal warehousing's focus on proximity and rapid last-mile delivery.

What is Hyperlocal Warehousing?

Hyperlocal warehousing refers to small-scale storage facilities located close to the end consumers, enabling faster order fulfillment and reduced last-mile delivery costs. Unlike bulk storage warehouses that store large volumes of goods centralized in one location, hyperlocal warehouses focus on inventory decentralization to support quick and efficient delivery in specific geographic areas. This approach enhances customer satisfaction by shortening delivery times and improving supply chain responsiveness.

Key Differences Between Bulk Storage and Hyperlocal Warehousing

Bulk storage warehouses typically manage large volumes of inventory in centralized locations, optimizing space for long-term storage and cost efficiency. Hyperlocal warehousing focuses on distributing inventory closer to end consumers, enhancing delivery speed and flexibility through smaller, strategically placed facilities. The key differences lie in scale, geographic proximity to customers, and operational agility tailored to fast fulfillment needs versus consolidated inventory management.

Advantages of Bulk Storage

Bulk storage offers significant advantages in warehousing by maximizing space utilization through the consolidation of large inventory volumes in a single location. This method reduces handling costs and simplifies inventory management by minimizing product fragmentation. Economies of scale achieved in bulk storage improve cost-efficiency, making it ideal for businesses with steady demand and large shipment sizes.

Benefits of Hyperlocal Warehousing

Hyperlocal warehousing offers faster delivery times by positioning inventory closer to end consumers, reducing last-mile transportation costs significantly. It enhances inventory accuracy and flexibility, allowing businesses to respond swiftly to local demand fluctuations and minimize stockouts. This decentralized approach improves customer satisfaction through quicker order fulfillment and supports sustainable logistics by lowering carbon emissions associated with long-distance shipping.

Cost Considerations: Bulk Storage vs Hyperlocal Warehousing

Bulk storage facilities generally offer lower per-unit storage costs due to economies of scale but incur higher transportation expenses and longer delivery times. Hyperlocal warehousing reduces last-mile delivery costs and speeds up fulfillment by positioning inventory closer to end customers, though it involves higher setup and operational expenses for multiple small facilities. Evaluating the balance between lower storage costs and increased distribution expenses is essential for optimizing overall warehousing cost efficiency.

Impact on Delivery Speed and Customer Satisfaction

Bulk storage facilities centralize inventory in large warehouses, often extending delivery times due to greater distances from end customers. Hyperlocal warehousing strategically places smaller inventories closer to demand hotspots, significantly reducing last-mile delivery times and boosting customer satisfaction through faster order fulfillment. This localized approach aligns with growing consumer expectations for same-day or next-day delivery, driving competitive advantage in e-commerce and retail sectors.

Scalability in Bulk Storage and Hyperlocal Models

Bulk storage offers significant scalability by accommodating large volumes of goods in centralized warehouses, enabling cost-efficient management of inventory and streamlined logistics for high-demand products. Hyperlocal warehousing emphasizes flexible, smaller storage units strategically located close to end customers, facilitating rapid fulfillment and enabling scalable expansion in urban markets through localized inventory distribution. Both models provide scalable solutions, with bulk storage excelling in volume capacity and cost-effectiveness, while hyperlocal warehousing offers agility and speed in last-mile delivery.

Technology Integration in Both Warehousing Approaches

Bulk storage facilities leverage advanced warehouse management systems (WMS) for efficient inventory tracking and automation, optimizing space utilization and order fulfillment at a large scale. Hyperlocal warehousing incorporates IoT devices and real-time data analytics to enhance last-mile delivery precision and speed in densely populated urban areas. Both approaches integrate AI-driven demand forecasting and robotics to improve operational accuracy and responsiveness, tailored to their specific logistics challenges.

Choosing the Right Warehousing Solution for Your Business

Bulk storage offers cost-effective solutions for storing large inventory volumes in centralized locations, ideal for businesses with predictable demand and long-term storage needs. Hyperlocal warehousing enhances fulfillment speed and reduces last-mile delivery costs by positioning smaller warehouses closer to end customers, supporting businesses with fluctuating demand or rapid delivery requirements. Evaluating factors like order volume, delivery speed, inventory turnover, and geographic customer distribution is essential for selecting the warehousing model that maximizes operational efficiency and customer satisfaction.

Related Important Terms

Micro-fulfillment Centers (MFCs)

Micro-fulfillment centers (MFCs) revolutionize hyperlocal warehousing by enabling rapid order fulfillment within urban areas, reducing last-mile delivery costs and transit times compared to traditional bulk storage facilities. These compact, technology-driven hubs optimize inventory management through automation and AI, meeting the rising demand for same-day or next-day delivery in e-commerce and grocery sectors.

Urban Bulk Hubs

Urban Bulk Hubs in warehousing offer a strategic advantage by combining the large capacity of bulk storage with the proximity benefits of hyperlocal warehousing, enabling efficient inventory management and swift last-mile delivery in densely populated areas. These hubs optimize space utilization while supporting faster replenishment cycles, reducing transportation costs and enhancing supply chain responsiveness.

Dark Warehousing

Bulk storage warehouses store large quantities of goods in centralized locations optimized for inventory management and cost efficiency, while hyperlocal warehousing emphasizes proximity to end consumers, enabling faster delivery times. Dark warehousing operates without on-site staff, leveraging automation and remote monitoring to maximize efficiency and reduce overhead in both bulk and hyperlocal settings.

End-Mile Storage

Bulk storage facilities focus on centralized inventory management, optimizing large-scale stock holding to benefit from economies of scale. Hyperlocal warehousing enhances end-mile delivery efficiency by positioning inventory closer to customers, reducing transit times and improving last-mile fulfillment speed.

Last-Touch Fulfillment

Bulk storage facilities centralize inventory in large warehouses, optimizing cost-efficiency but increasing last-mile delivery times, while hyperlocal warehousing locates smaller stockpiles near end customers to enhance last-touch fulfillment speed and accuracy. Prioritizing hyperlocal warehousing improves same-day delivery capabilities and customer satisfaction by reducing transit distances in last-mile logistics.

Nano Warehousing

Nano warehousing, a form of hyperlocal warehousing, optimizes last-mile delivery by utilizing small, strategically located storage units closer to end consumers, reducing transit times and enhancing supply chain agility. Unlike traditional bulk storage facilities that handle large volumes in centralized locations, nano warehouses cater to rapid order fulfillment for e-commerce and urban distribution networks, minimizing inventory holding costs and improving responsiveness.

Decentralized Inventory Nodes

Decentralized inventory nodes in hyperlocal warehousing reduce delivery times and enhance customer satisfaction by positioning stock closer to demand centers. In contrast, bulk storage relies on centralized warehouses, which optimize storage costs but may increase last-mile delivery complexities and delays.

On-Demand Warehousing

On-demand warehousing bridges the efficiency of bulk storage with the flexibility of hyperlocal warehousing by allowing businesses to temporarily rent warehouse space near key markets, reducing last-mile delivery times and inventory holding costs. This approach optimizes supply chain responsiveness and scalability, leveraging real-time location data and dynamic capacity management to meet fluctuating demand without the long-term commitments of traditional bulk storage.

Dynamic Stock Pooling

Dynamic stock pooling in bulk storage centralizes inventory to optimize space utilization and reduce holding costs, enabling large-scale aggregation of goods in a single location. Hyperlocal warehousing leverages dynamic stock pooling by distributing smaller inventory quantities across multiple proximate warehouses, enhancing delivery speed and responsiveness to local demand fluctuations.

Pop-Up Distribution Centers

Pop-up distribution centers leverage hyperlocal warehousing by situating inventory closer to demand hotspots, enabling faster delivery and reducing last-mile logistics costs compared to traditional bulk storage warehouses. This strategic placement supports real-time inventory management and enhances supply chain agility in high-density urban areas.

Bulk Storage vs Hyperlocal Warehousing Infographic

industrydif.com

industrydif.com