Pallet racking offers a cost-effective and flexible solution for storing large quantities of goods, providing easy manual access and maximizing warehouse space vertically. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency by minimizing labor costs and increasing accuracy through automated handling and retrieval of pallets. Choosing between pallet racking and AS/RS depends on factors such as inventory turnover rate, budget, and the need for speed and precision in warehouse operations.

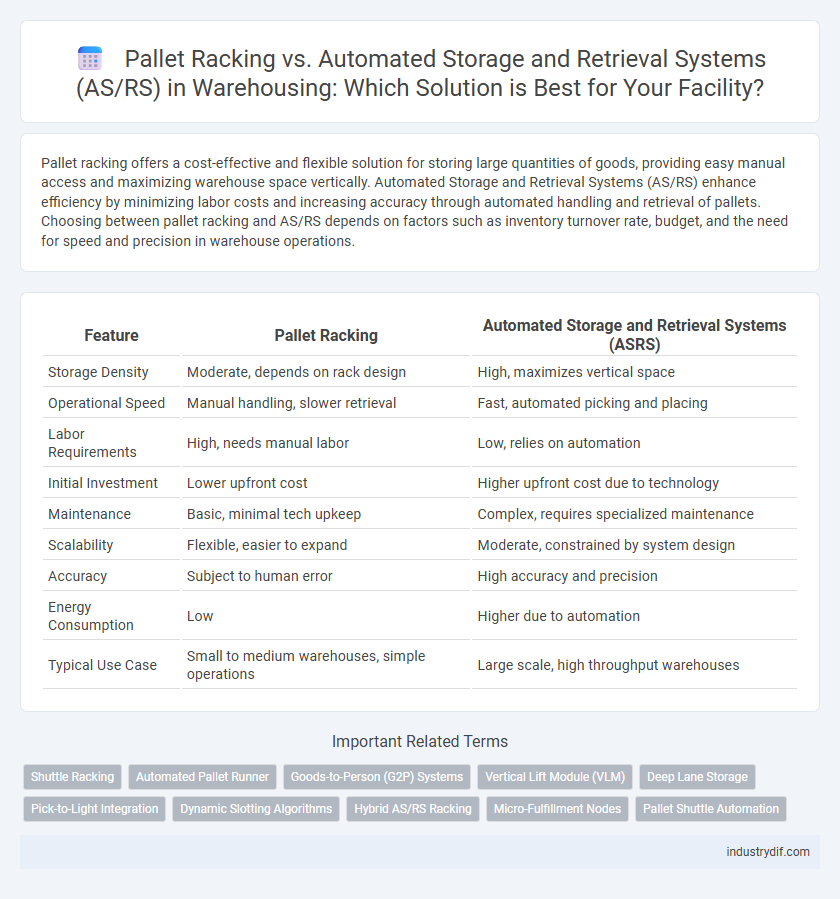

Table of Comparison

| Feature | Pallet Racking | Automated Storage and Retrieval Systems (ASRS) |

|---|---|---|

| Storage Density | Moderate, depends on rack design | High, maximizes vertical space |

| Operational Speed | Manual handling, slower retrieval | Fast, automated picking and placing |

| Labor Requirements | High, needs manual labor | Low, relies on automation |

| Initial Investment | Lower upfront cost | Higher upfront cost due to technology |

| Maintenance | Basic, minimal tech upkeep | Complex, requires specialized maintenance |

| Scalability | Flexible, easier to expand | Moderate, constrained by system design |

| Accuracy | Subject to human error | High accuracy and precision |

| Energy Consumption | Low | Higher due to automation |

| Typical Use Case | Small to medium warehouses, simple operations | Large scale, high throughput warehouses |

Introduction to Modern Warehousing Solutions

Pallet racking systems offer a cost-effective and flexible solution for organized storage of bulk goods, optimizing warehouse space by utilizing vertical height efficiently. Automated Storage and Retrieval Systems (AS/RS) integrate robotics and software to enhance inventory management, increase picking speed, and reduce labor costs in high-volume warehouses. Modern warehousing solutions combine traditional racking infrastructure with AS/RS technology to improve operational efficiency and accommodate complex supply chain demands.

Overview of Pallet Racking Systems

Pallet racking systems are a foundational component of warehouse storage, designed to maximize space by organizing palletized goods vertically and horizontally. These systems enable efficient inventory management through various configurations such as selective, drive-in, and push-back racking, each tailored to different load types and accessibility needs. Their structural design supports heavy loads while optimizing floor space, making them essential for traditional warehousing operations compared to automated storage and retrieval systems (AS/RS), which offer more technological integration and automation.

What is Automated Storage and Retrieval (AS/RS)?

Automated Storage and Retrieval Systems (AS/RS) are advanced warehouse technologies designed to automatically place and retrieve loads from predefined storage locations, significantly improving space utilization and operational efficiency. These systems use cranes, shuttles, or conveyors controlled by software to minimize manual labor and reduce errors in inventory handling. AS/RS is ideal for high-density storage needs and environments requiring fast, accurate, and consistent order fulfillment.

Core Differences: Manual vs Automated Storage

Pallet racking systems rely on manual handling, requiring forklift operators to place and retrieve goods, which can lead to slower processing times and higher labor costs. Automated Storage and Retrieval Systems (AS/RS) use computerized controls and robotic shuttles to efficiently manage inventory movement, enhancing accuracy and reducing human error. The core difference lies in manual intervention versus automated precision, impacting operational speed, labor requirements, and overall warehouse productivity.

Space Utilization and Warehouse Layout Efficiency

Pallet racking systems maximize vertical space by allowing high-density storage but often require wider aisles for forklift access, which can reduce overall floor space utilization. Automated Storage and Retrieval Systems (AS/RS) enhance warehouse layout efficiency by minimizing aisle width and utilizing compact storage configurations, significantly increasing storage capacity within the same footprint. Implementing AS/RS leads to improved space utilization through optimized inventory flow and reduced manual handling areas.

Cost Considerations: Initial Investment vs Long-term ROI

Pallet racking systems generally require a lower initial investment compared to automated storage and retrieval systems (AS/RS), making them attractive for budget-conscious warehouses. However, AS/RS solutions offer higher long-term ROI through labor savings, increased storage density, and improved inventory accuracy, which reduce operational costs over time. Cost considerations should balance upfront capital expenses with potential efficiency gains and reduced error rates provided by automation technology.

Scalability and Flexibility for Growing Operations

Pallet racking systems offer scalable storage solutions that can be easily expanded by adding more racks, making them ideal for growing warehouse operations with variable inventory volumes. Automated Storage and Retrieval Systems (AS/RS) provide high flexibility through programmable configurations and faster inventory handling, which supports dynamic order fulfillment and space optimization. Growing businesses benefit from the combination of pallet racking's modular scalability and AS/RS's adaptable technology to efficiently manage increasing storage demands.

Labor Requirements and Operational Efficiency

Pallet racking systems typically demand higher labor input for manual picking, stacking, and retrieval, leading to increased time and human resource costs. Automated Storage and Retrieval Systems (AS/RS) significantly reduce labor requirements by using robotics and software to handle inventory, enhancing operational efficiency through faster cycle times and minimized errors. Implementing AS/RS improves throughput and accuracy, translating to lower labor expenses and optimized warehouse productivity.

Safety Implications in Storage Systems

Pallet racking systems pose higher safety risks due to manual handling and potential structural failures, whereas Automated Storage and Retrieval Systems (AS/RS) significantly reduce human interaction with heavy loads, minimizing injury hazards. AS/RS incorporate advanced sensors, safety interlocks, and automated controls to prevent accidents and ensure stable load management. Warehouses implementing AS/RS report decreased workplace incidents and enhanced compliance with occupational safety standards compared to traditional pallet racking setups.

Choosing the Right Solution for Your Warehouse Needs

Pallet racking offers a cost-effective, flexible storage solution ideal for warehouses with varying inventory sizes and manual handling. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency and accuracy by using robotics and software, suitable for high-volume operations requiring fast, precise picking. Selecting between pallet racking and AS/RS depends on factors such as warehouse size, inventory turnover rate, labor availability, and budget constraints.

Related Important Terms

Shuttle Racking

Shuttle racking maximizes warehouse efficiency by combining high-density storage with automated shuttle systems that swiftly move pallets within bays, reducing labor and increasing throughput compared to traditional pallet racking. Unlike standard pallet racking, shuttle racking optimizes space utilization and retrieval speed, making it ideal for warehouses with high volume and dynamic inventory turnover.

Automated Pallet Runner

Automated Pallet Runner systems enhance warehouse efficiency by enabling high-density storage and fast, precise retrieval of pallets with minimal human intervention. Compared to traditional pallet racking, these systems reduce labor costs, optimize space utilization, and increase throughput by automating the movement of pallets along designated lanes.

Goods-to-Person (G2P) Systems

Pallet racking systems provide efficient high-density storage but require significant manual labor for picking, whereas automated Goods-to-Person (G2P) systems dramatically increase productivity by delivering items directly to operators using robotics and conveyors. G2P solutions reduce travel time, improve accuracy, and optimize space utilization, making them ideal for high-volume warehouses seeking advanced automation and streamlined order fulfillment.

Vertical Lift Module (VLM)

Pallet racking systems maximize horizontal warehouse space but often limit vertical storage efficiency compared to Automated Storage and Retrieval Systems (AS/RS) like Vertical Lift Modules (VLM), which optimize vertical space by automatically delivering items with high precision and speed. VLMs enhance inventory management accuracy and reduce labor costs through automation, providing superior space utilization and faster order fulfillment in high-density warehousing environments.

Deep Lane Storage

Deep lane storage in pallet racking maximizes vertical space by stacking pallets multiple rows deep, allowing high-density storage but requiring forklift access for retrieval. Automated Storage and Retrieval Systems (AS/RS) enhance this by using robotic shuttles or cranes to access pallets deep within lanes, increasing retrieval speed and accuracy while reducing labor costs.

Pick-to-Light Integration

Pallet racking systems enhance warehouse storage density, but integrating pick-to-light technology with automated storage and retrieval systems (AS/RS) significantly boosts picking accuracy and speed by providing real-time visual cues directly at the storage location. This integration reduces labor costs and errors while improving overall operational efficiency in high-volume fulfillment environments.

Dynamic Slotting Algorithms

Dynamic slotting algorithms optimize inventory placement by continuously analyzing SKU velocity, demand patterns, and replenishment cycles, enhancing storage density in pallet racking systems. In automated storage and retrieval systems (AS/RS), these algorithms increase throughput and reduce retrieval time by dynamically assigning products to optimal locations based on real-time order data and system constraints.

Hybrid AS/RS Racking

Hybrid AS/RS racking systems combine traditional pallet racking with automated storage and retrieval technologies, optimizing warehouse space utilization and increasing throughput efficiency. This integration supports dynamic inventory management by enabling both manual access and automated handling, reducing labor costs while maintaining flexibility for diverse storage needs.

Micro-Fulfillment Nodes

Micro-fulfillment nodes leverage automated storage and retrieval systems (ASRS) to maximize space efficiency and accelerate order processing compared to traditional pallet racking, which typically requires more manual handling and larger footprint. ASRS solutions integrate robotics and AI technologies, enabling higher throughput and precise inventory management critical for urban and last-mile distribution centers.

Pallet Shuttle Automation

Pallet shuttle automation enhances traditional pallet racking systems by using automated shuttles to transport goods within storage lanes, significantly increasing storage density and retrieval speed compared to manual handling. This technology reduces labor costs and operational errors while maximizing space utilization in warehouses with high SKU variability and throughput demands.

Pallet Racking vs Automated Storage and Retrieval Infographic

industrydif.com

industrydif.com