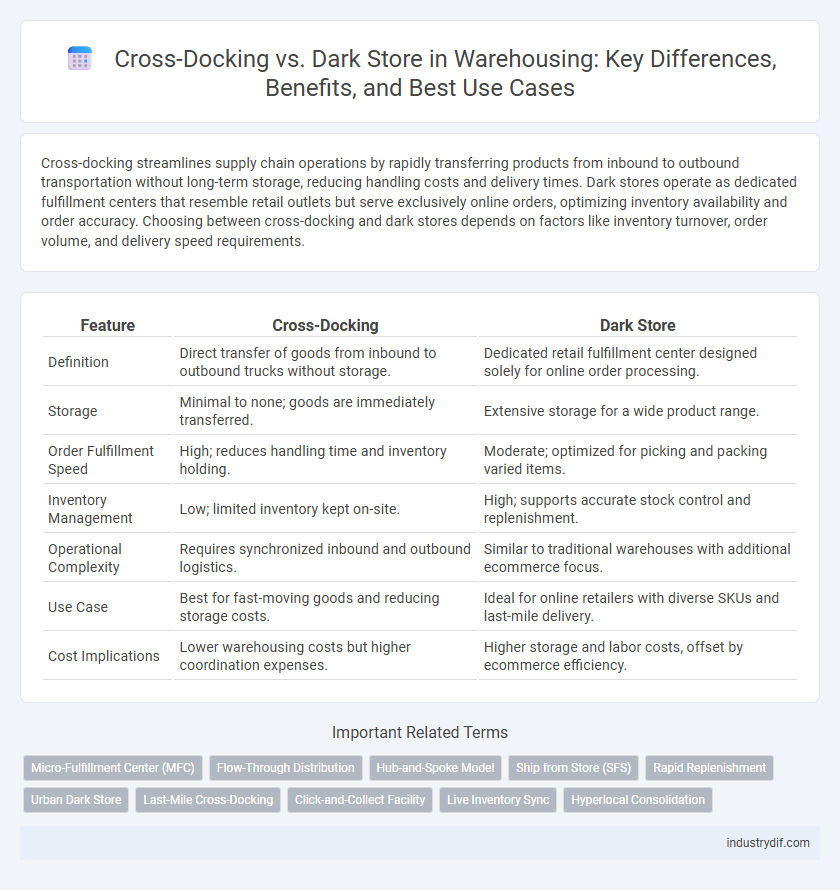

Cross-docking streamlines supply chain operations by rapidly transferring products from inbound to outbound transportation without long-term storage, reducing handling costs and delivery times. Dark stores operate as dedicated fulfillment centers that resemble retail outlets but serve exclusively online orders, optimizing inventory availability and order accuracy. Choosing between cross-docking and dark stores depends on factors like inventory turnover, order volume, and delivery speed requirements.

Table of Comparison

| Feature | Cross-Docking | Dark Store |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound trucks without storage. | Dedicated retail fulfillment center designed solely for online order processing. |

| Storage | Minimal to none; goods are immediately transferred. | Extensive storage for a wide product range. |

| Order Fulfillment Speed | High; reduces handling time and inventory holding. | Moderate; optimized for picking and packing varied items. |

| Inventory Management | Low; limited inventory kept on-site. | High; supports accurate stock control and replenishment. |

| Operational Complexity | Requires synchronized inbound and outbound logistics. | Similar to traditional warehouses with additional ecommerce focus. |

| Use Case | Best for fast-moving goods and reducing storage costs. | Ideal for online retailers with diverse SKUs and last-mile delivery. |

| Cost Implications | Lower warehousing costs but higher coordination expenses. | Higher storage and labor costs, offset by ecommerce efficiency. |

Introduction to Cross-Docking and Dark Store Concepts

Cross-docking streamlines the supply chain by transferring products directly from inbound to outbound transportation, minimizing storage time and reducing inventory costs. Dark stores function as dedicated fulfillment centers optimized for online orders, designed to expedite picking and packing without serving walk-in customers. Both models enhance efficiency in warehousing but cater to different logistics strategies and consumer demand patterns.

Key Differences Between Cross-Docking and Dark Stores

Cross-docking minimizes storage time by directly transferring products from inbound to outbound transportation, enhancing supply chain speed and reducing inventory holding costs. Dark stores operate as local fulfillment centers without customer access, optimizing order picking for e-commerce and fast delivery within urban areas. Key differences lie in cross-docking's focus on rapid distribution versus dark stores' emphasis on efficient, small-batch order processing in a controlled retail-like environment.

Cross-Docking: Definition, Process, and Advantages

Cross-docking is a logistics strategy where products from suppliers are directly transferred to outbound transportation with minimal or no storage time, accelerating the supply chain. The process involves receiving incoming goods at a dock, sorting, and immediately shipping them to their next destination, reducing inventory holding costs and improving delivery speed. Advantages of cross-docking include enhanced inventory turnover, reduced warehousing expenses, and faster order fulfillment, making it ideal for perishable goods and time-sensitive shipments.

Dark Stores: Definition, Operation, and Benefits

Dark stores are specialized fulfillment centers designed exclusively for online order processing, operating without direct customer access to optimize inventory management and speed. These facilities utilize advanced inventory systems and layout designs to streamline picking, packing, and shipping, reducing delivery times significantly. Benefits include increased operational efficiency, enhanced product availability, and the ability to serve high-demand urban areas with faster last-mile delivery options.

Inventory Management Strategies in Cross-Docking vs Dark Stores

Cross-docking minimizes inventory holding by transferring goods directly from inbound to outbound transportation, reducing storage time and costs. Dark stores operate as dedicated fulfillment centers with extensive inventory, enabling rapid order processing for e-commerce and local delivery. Effective inventory management in cross-docking centers relies on precise timing and coordination, while dark stores focus on inventory accuracy and real-time stock visibility to meet consumer demand efficiently.

Impact on Supply Chain Efficiency

Cross-docking reduces storage time and accelerates product flow by transferring goods directly from inbound to outbound transportation, minimizing inventory holding costs and enhancing supply chain responsiveness. Dark stores, designed as fulfillment centers without customer-facing services, optimize last-mile delivery speed and order accuracy by consolidating inventory closer to high-demand areas. Both strategies improve supply chain efficiency but address different operational challenges: cross-docking excels in rapid throughput, while dark stores focus on streamlined e-commerce fulfillment.

Technology and Automation in Cross-Docking and Dark Stores

Cross-docking leverages advanced technologies such as real-time inventory tracking, automated sorting systems, and conveyor belts to expedite the direct transfer of goods from inbound to outbound transportation, minimizing storage time. Dark stores employ automated picking robots, AI-driven inventory management, and smart shelving systems to efficiently fulfill online orders within a localized warehouse environment. Both models integrate IoT sensors and data analytics to optimize operational efficiency, but cross-docking emphasizes rapid flow-through facilitated by automation, while dark stores focus on precise, high-velocity order fulfillment through robotic assistance.

Cost Implications and ROI Analysis

Cross-docking significantly reduces storage costs by minimizing inventory holding and accelerating throughput, leading to improved cash flow and faster return on investment compared to traditional warehousing models. Dark stores require higher initial capital expenditure for dedicated retail fulfillment facilities but offer scalable benefits in urban last-mile delivery efficiency, enhancing ROI in dense markets. Evaluating cost implications and ROI involves analyzing factors such as labor expenses, transportation savings, inventory turnover rates, and fulfillment speed to determine the optimal strategy for specific supply chain needs.

Industry Applications and Use Cases

Cross-docking optimizes supply chain efficiency by enabling rapid transfer of goods directly from inbound to outbound transportation, minimizing storage time and reducing inventory holding costs in industries like retail, e-commerce, and perishable goods. Dark stores serve as localized fulfillment centers designed for online order processing, primarily used in grocery, fashion, and fast-moving consumer goods sectors to accelerate last-mile delivery and improve urban inventory accessibility. Both solutions address distinct logistics challenges: cross-docking excels in high-volume, time-sensitive distribution, while dark stores enhance customer experience through faster delivery in densely populated markets.

Future Trends in Warehousing: Cross-Docking vs Dark Stores

Future trends in warehousing highlight the growing adoption of cross-docking to accelerate inventory turnover and reduce storage costs by minimizing handling times between inbound and outbound shipments. Dark stores are evolving as strategic fulfillment hubs optimized for rapid e-commerce delivery, leveraging automation and real-time inventory management to meet increasing consumer demand for same-day shipping. Integration of AI-driven analytics and IoT technology is expected to enhance operational efficiency in both cross-docking and dark store models, enabling smarter resource allocation and predictive logistics.

Related Important Terms

Micro-Fulfillment Center (MFC)

Cross-docking streamlines inventory movement by transferring goods directly from inbound to outbound transportation, reducing storage time in Micro-Fulfillment Centers (MFCs) and accelerating order fulfillment. Dark stores function as localized warehouses within MFCs, optimizing last-mile delivery by storing and picking products closer to urban consumers, enhancing speed and efficiency in e-commerce logistics.

Flow-Through Distribution

Cross-docking streamlines flow-through distribution by minimizing storage time, enabling goods to move directly from inbound to outbound transportation, thus increasing efficiency in high-turnover environments. Dark stores function as dedicated fulfillment centers for online orders, optimizing flow-through by allowing rapid picking and packing without customer-facing operations, improving speed in last-mile delivery.

Hub-and-Spoke Model

Cross-docking serves as a pivotal strategy within the hub-and-spoke model, enabling swift transfer of goods from inbound to outbound transportation with minimal storage time, optimizing delivery speed and reducing inventory holding costs. In contrast, dark stores function as fulfillment hubs in the same model, acting as mini-warehouses that store inventory for rapid order picking and local last-mile delivery, enhancing e-commerce efficiency and customer response times.

Ship from Store (SFS)

Cross-docking streamlines inventory flow by transferring goods directly from inbound to outbound shipments, minimizing storage time and accelerating Ship from Store (SFS) operations. Dark stores, optimized for SFS, serve as localized fulfillment centers that enhance delivery speed and inventory accuracy by storing products closer to end customers.

Rapid Replenishment

Cross-docking minimizes storage time by directly transferring goods from inbound to outbound transport, enabling rapid replenishment and reducing inventory holding costs. Dark stores act as localized fulfillment centers, optimizing order picking and accelerating delivery speed to meet increasing consumer demand for quick shipments.

Urban Dark Store

Urban dark stores optimize last-mile delivery by serving as miniature warehouses located within city centers, drastically reducing delivery times compared to traditional cross-docking facilities that rely on inbound consolidation and outbound distribution hubs. Unlike cross-docking, which primarily manages flow between suppliers and retailers, urban dark stores hold inventory closer to consumers, enabling rapid fulfillment and enhanced e-commerce efficiency in dense metropolitan areas.

Last-Mile Cross-Docking

Last-mile cross-docking optimizes delivery speed by transferring products directly from inbound to outbound transportation without intermediate storage, reducing handling time and inventory costs associated with dark stores. This approach enhances supply chain efficiency by leveraging real-time inventory flow and minimizing delays common in order preparation typical of dark store operations.

Click-and-Collect Facility

Cross-docking optimizes click-and-collect facilities by rapidly transferring inbound goods directly to outbound vehicles, reducing storage time and enhancing order fulfillment speed. Dark stores serve as inventory-dedicated hubs for click-and-collect, improving product availability and pick accuracy without traditional retail space constraints.

Live Inventory Sync

Cross-docking optimizes live inventory sync by rapidly transferring products from inbound to outbound shipments, minimizing storage time and reducing inventory discrepancies. In contrast, dark stores maintain a continuously updated inventory system for real-time order fulfillment, enhancing accuracy but requiring dedicated storage space and more complex inventory management.

Hyperlocal Consolidation

Cross-docking streamlines hyperlocal consolidation by rapidly transferring goods between inbound and outbound vehicles, minimizing storage time and accelerating last-mile delivery. Dark stores enhance this process by operating as dedicated fulfillment centers optimized for online orders, enabling faster aggregation and dispatch of hyperlocal inventory.

Cross-Docking vs Dark Store Infographic

industrydif.com

industrydif.com