Traditional pallet racking offers a cost-effective and straightforward storage solution ideal for warehouses with predictable inventory and lower throughput demands. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency by minimizing human error and maximizing space utilization through robotic precision and real-time inventory management. Choosing between these options depends on factors like warehouse size, throughput requirements, and investment capacity.

Table of Comparison

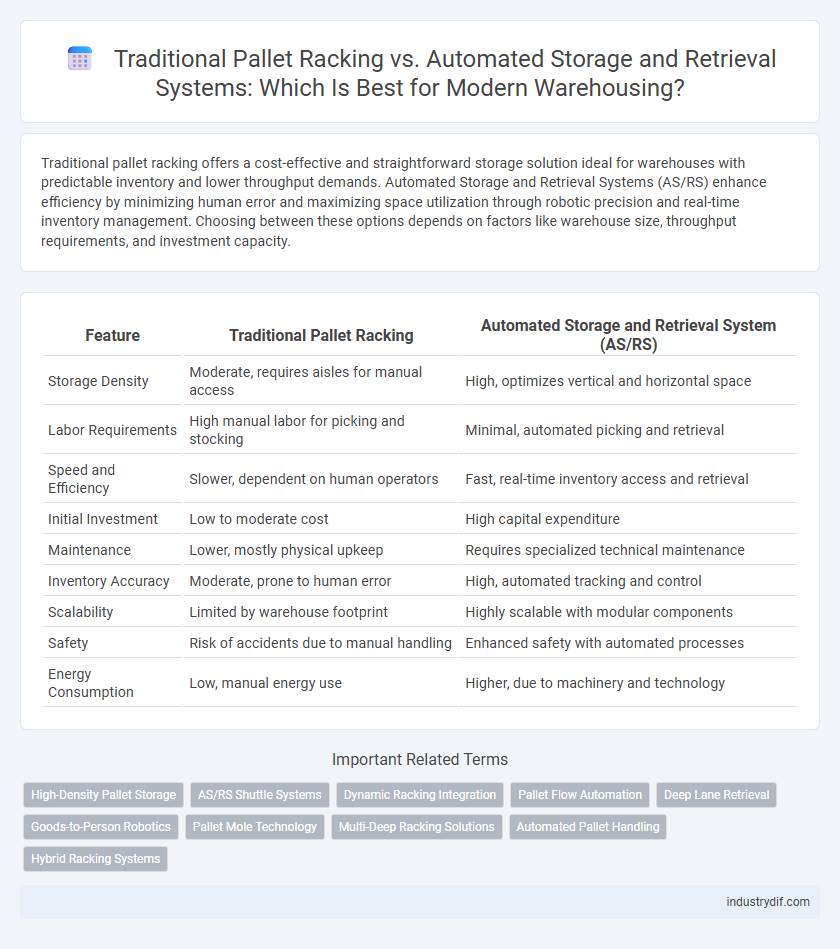

| Feature | Traditional Pallet Racking | Automated Storage and Retrieval System (AS/RS) |

|---|---|---|

| Storage Density | Moderate, requires aisles for manual access | High, optimizes vertical and horizontal space |

| Labor Requirements | High manual labor for picking and stocking | Minimal, automated picking and retrieval |

| Speed and Efficiency | Slower, dependent on human operators | Fast, real-time inventory access and retrieval |

| Initial Investment | Low to moderate cost | High capital expenditure |

| Maintenance | Lower, mostly physical upkeep | Requires specialized technical maintenance |

| Inventory Accuracy | Moderate, prone to human error | High, automated tracking and control |

| Scalability | Limited by warehouse footprint | Highly scalable with modular components |

| Safety | Risk of accidents due to manual handling | Enhanced safety with automated processes |

| Energy Consumption | Low, manual energy use | Higher, due to machinery and technology |

Overview of Traditional Pallet Racking

Traditional pallet racking systems consist of steel frameworks designed to store palletized goods in warehouses, maximizing vertical space utilization. These systems typically require manual labor for inventory handling, relying on forklifts for loading and unloading pallets. Known for their cost-effectiveness and simplicity, traditional pallet racking offers flexibility but may limit efficiency compared to automated storage and retrieval systems (AS/RS).

Introduction to Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) revolutionize warehousing by utilizing computer-controlled systems to automatically place and retrieve loads from specific storage locations. Unlike traditional pallet racking, AS/RS enhances storage density, improves accuracy, and reduces labor costs through robotics and software integration. This technology optimizes inventory management, accelerates order fulfillment, and supports just-in-time operations in modern distribution centers.

Space Utilization: Pallet Racking vs AS/RS

Traditional pallet racking systems typically utilize 60-70% of warehouse space due to fixed aisle widths and manual access requirements, limiting vertical storage capacity. Automated Storage and Retrieval Systems (AS/RS) improve space utilization by reducing aisle widths to as narrow as 24 inches and maximizing vertical storage up to the warehouse ceiling, achieving space utilization rates exceeding 85-90%. This enhancement enables higher storage density and optimized floor space, contributing to increased inventory capacity within the same footprint.

Efficiency and Throughput Comparison

Traditional pallet racking offers straightforward storage with moderate speed in retrieval, relying heavily on manual labor, which can limit throughput during peak operations. Automated Storage and Retrieval Systems (AS/RS) dramatically increase efficiency by using robotics and software to expedite picking processes, reducing errors and labor costs while maximizing space utilization. AS/RS enables higher throughput rates, continuous operation, and real-time inventory management, making it ideal for warehouses seeking scalable and optimized performance.

Cost Implications: Initial Investment and Maintenance

Traditional pallet racking requires a lower initial investment compared to Automated Storage and Retrieval Systems (AS/RS), making it accessible for smaller warehouses with limited budgets. However, AS/RS systems, despite higher upfront costs, offer reduced labor expenses and lower ongoing maintenance due to automation and improved system diagnostics, potentially leading to long-term savings. Maintenance costs for traditional pallet racks typically involve physical wear and manual inspection, whereas AS/RS maintenance demands specialized technical support and software updates.

Flexibility and Scalability in Warehousing

Traditional pallet racking offers straightforward scalability by simply adding more racks but lacks the flexibility to handle varied product sizes efficiently. Automated Storage and Retrieval Systems (AS/RS) provide high flexibility, adapting easily to changing inventory types and optimized space utilization through dynamic storage configurations. AS/RS solutions enhance scalability by enabling rapid system expansion with minimal disruption, supporting growing warehouse demands effectively.

Labor Requirements and Workforce Impact

Traditional pallet racking demands higher manual labor input for tasks such as picking, stacking, and inventory management, increasing the risk of worker fatigue and injury. Automated Storage and Retrieval Systems (AS/RS) significantly reduce labor requirements by utilizing robotic technology to handle storage and retrieval processes, enhancing operational efficiency and accuracy. Workforce impact includes a shift toward skilled positions for system maintenance and oversight, emphasizing the need for technical training and reducing physical strain on employees.

Safety and Risk Management Considerations

Traditional pallet racking systems pose higher risks of structural failure and worker injury due to manual handling and forklift operations, making regular inspections and safety protocols critical. Automated Storage and Retrieval Systems (AS/RS) enhance safety by minimizing human interaction with heavy loads and reducing forklift traffic, thereby lowering accidents and damage. Integrating AS/RS requires rigorous risk assessments and maintenance to ensure system reliability and protect personnel from mechanical hazards.

Technology Integration and Data Management

Traditional pallet racking relies on manual inventory management and limited technology integration, resulting in slower data updates and higher error rates. Automated Storage and Retrieval Systems (AS/RS) utilize advanced sensors, real-time data analytics, and IoT connectivity to optimize storage space and streamline inventory tracking. Integration with warehouse management software (WMS) enhances accuracy, reduces labor costs, and supports data-driven decision-making for improved operational efficiency.

Choosing the Right Solution for Your Warehouse

Traditional pallet racking offers cost-effective, flexible storage ideal for warehouses with predictable inventory flow and manual handling operations. Automated Storage and Retrieval Systems (AS/RS) maximize space utilization and efficiency through real-time inventory management, reducing labor costs and picking errors in high-volume environments. Evaluating warehouse size, throughput requirements, and budget constraints is crucial for selecting between traditional racking and AS/RS to optimize productivity and operational ROI.

Related Important Terms

High-Density Pallet Storage

Traditional pallet racking systems offer straightforward, accessible storage but often require more aisle space, limiting overall storage density. Automated Storage and Retrieval Systems (AS/RS) maximize high-density pallet storage by utilizing vertical space efficiently and reducing aisle widths through automated retrieval, significantly increasing warehouse storage capacity and inventory management precision.

AS/RS Shuttle Systems

Automated Storage and Retrieval System (AS/RS) Shuttle Systems enhance warehouse efficiency by using high-speed shuttles to move pallets within densely packed racks, significantly increasing storage density and reducing retrieval times compared to traditional pallet racking. This technology optimizes space utilization and minimizes labor costs through automation, enabling just-in-time inventory management and improving overall operational throughput.

Dynamic Racking Integration

Dynamic racking integration in warehousing enhances operational efficiency by combining Traditional Pallet Racking's high-density storage capacity with Automated Storage and Retrieval Systems (AS/RS) precision and speed. This synergy optimizes space utilization, reduces labor costs, and accelerates inventory throughput, making it ideal for warehouses demanding flexibility and scalability.

Pallet Flow Automation

Traditional pallet racking maximizes vertical storage space with static shelving, while Pallet Flow Automation in automated storage and retrieval systems (AS/RS) uses gravity-driven rollers to enable high-density, first-in-first-out (FIFO) inventory management and faster pallet movement. This automation reduces labor costs, minimizes human error, and improves warehouse throughput by streamlining pallet replenishment and picking processes.

Deep Lane Retrieval

Deep Lane Retrieval systems enhance storage density by enabling multi-depth pallet storage, significantly improving space utilization compared to traditional pallet racking. Automated Storage and Retrieval Systems (ASRS) in deep lane configurations reduce labor costs and retrieval times by using robotic shuttles or cranes for precise, high-speed pallet handling.

Goods-to-Person Robotics

Traditional pallet racking systems require workers to manually retrieve inventory, leading to slower order fulfillment and increased labor costs, while Automated Storage and Retrieval Systems (AS/RS) with Goods-to-Person robotics significantly enhance efficiency by delivering items directly to operators, reducing picking times by up to 50% and minimizing human error. Warehouses implementing AS/RS benefit from optimized space utilization, higher throughput rates, and improved inventory accuracy, driving overall operational productivity and cost savings.

Pallet Mole Technology

Traditional pallet racking offers cost-effective storage with straightforward access but lacks the efficiency and space optimization provided by Pallet Mole technology, which automates pallet movement using intelligent, autonomous vehicles. Pallet Mole systems increase storage density by dynamically navigating tight aisles, reducing labor costs, and improving order accuracy in modern warehousing operations.

Multi-Deep Racking Solutions

Multi-deep racking solutions in traditional pallet racking maximize warehouse space by allowing multiple pallets to be stored in depth but require specialized forklift operations for access, leading to potential inefficiencies. Automated Storage and Retrieval Systems (AS/RS) optimize multi-deep storage with precise robotic retrieval, reducing labor costs, minimizing errors, and increasing throughput in high-density inventory management.

Automated Pallet Handling

Automated Pallet Handling systems significantly enhance warehouse efficiency by reducing manual labor and minimizing errors through robotic conveyors, automated stackers, and shuttle systems. These systems optimize space utilization, accelerate inventory retrieval, and improve safety compared to traditional pallet racking methods.

Hybrid Racking Systems

Hybrid racking systems combine the space efficiency of traditional pallet racking with the technological advancements of automated storage and retrieval systems (AS/RS), optimizing warehouse storage density and operational speed. Integrating manual and automated components, these systems enhance inventory accuracy and reduce labor costs while maintaining flexibility for diverse product handling.

Traditional Pallet Racking vs Automated Storage and Retrieval System Infographic

industrydif.com

industrydif.com