Pallet racking systems provide a traditional, cost-effective solution for organized storage with easy access to goods, ideal for warehouses with moderate inventory turnover. Robotic shuttle systems enhance storage density and speed by automating the movement of pallets within deep racks, significantly improving efficiency in high-volume or fast-paced environments. Choosing between the two depends on inventory size, turnover rate, and automation goals, with robotic shuttles offering scalability and reduced labor costs compared to manual pallet racking.

Table of Comparison

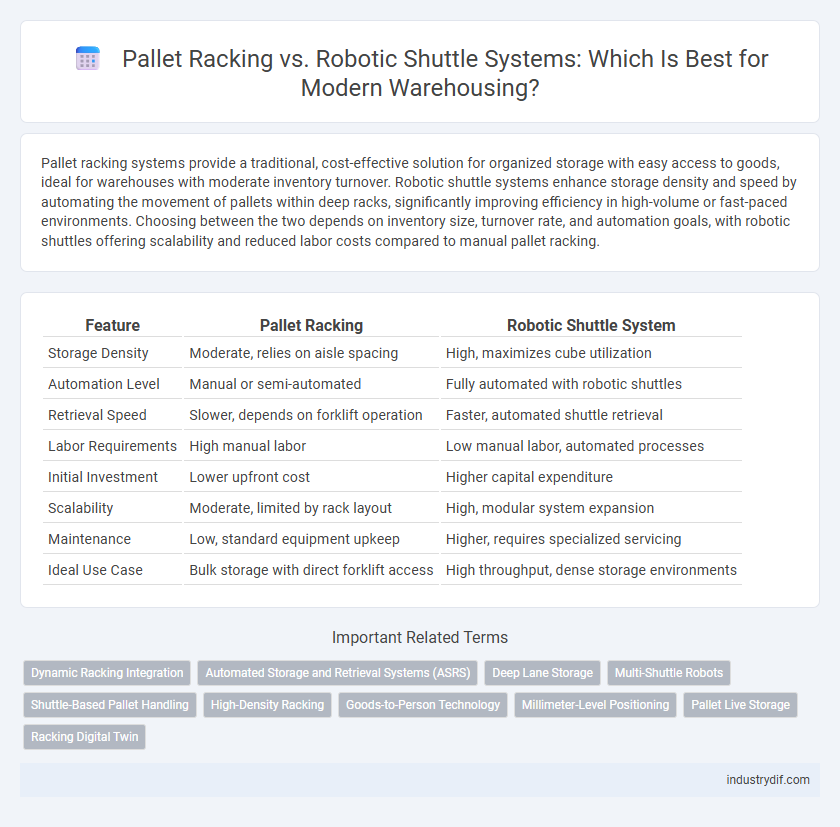

| Feature | Pallet Racking | Robotic Shuttle System |

|---|---|---|

| Storage Density | Moderate, relies on aisle spacing | High, maximizes cube utilization |

| Automation Level | Manual or semi-automated | Fully automated with robotic shuttles |

| Retrieval Speed | Slower, depends on forklift operation | Faster, automated shuttle retrieval |

| Labor Requirements | High manual labor | Low manual labor, automated processes |

| Initial Investment | Lower upfront cost | Higher capital expenditure |

| Scalability | Moderate, limited by rack layout | High, modular system expansion |

| Maintenance | Low, standard equipment upkeep | Higher, requires specialized servicing |

| Ideal Use Case | Bulk storage with direct forklift access | High throughput, dense storage environments |

Overview of Pallet Racking and Robotic Shuttle Systems

Pallet racking systems provide a traditional, cost-effective solution for organized storage, utilizing vertical space to increase warehouse capacity and facilitate easy access to pallets. Robotic shuttle systems offer advanced automation by employing autonomous shuttles to transport pallets within racks, enhancing efficiency, speed, and minimizing human intervention. Both systems optimize storage but differ significantly in terms of scalability, operational speed, and initial investment requirements.

Key Differences Between Pallet Racking and Robotic Shuttle Systems

Pallet racking systems utilize static structures where forklifts manually place and retrieve pallets, enabling high vertical storage density but limited picking speed. Robotic shuttle systems employ automated shuttles to transport pallets within dense grid structures, significantly increasing retrieval speed and reducing labor costs. Key differences include automation level, space utilization efficiency, and throughput capacity, with robotic shuttles offering superior scalability for high-volume warehouses.

Storage Density and Space Utilization

Pallet racking systems typically offer moderate storage density by stacking pallets vertically, which maximizes warehouse height but requires aisles for forklift access, limiting overall space utilization. Robotic shuttle systems enhance storage density significantly by enabling deep lane storage with automated shuttles that retrieve pallets, reducing aisle space and increasing active storage volume per square meter. This results in superior space utilization as robotic shuttles maximize horizontal and vertical space while minimizing aisle footprints, ideal for high-density warehousing operations.

Speed and Efficiency in Material Handling

Pallet racking systems offer a straightforward solution for storing large volumes of goods but typically rely on manual or forklift operations, which can limit speed and throughput. Robotic shuttle systems enhance material handling efficiency by automating storage and retrieval processes, significantly reducing cycle times and maximizing space utilization. Integration of advanced robotics and software enables faster inventory access and improved accuracy compared to conventional pallet racking.

Scalability for Growing Warehousing Needs

Pallet racking systems provide straightforward vertical storage solutions with limited scalability constrained by building height and layout, making them suitable for consistent inventory levels. Robotic shuttle systems offer dynamic scalability through modular design and automated shuttles, enabling efficient space utilization and quick adaptation to increasing storage demands. Integrating robotic shuttles enhances throughput and flexibility, supporting rapid warehouse expansion and evolving operational requirements.

Initial Investment and Long-term ROI

Pallet racking systems typically require a lower initial investment, making them accessible for small to medium-sized warehouses, while robotic shuttle systems demand a higher upfront cost due to advanced automation technology. Over time, robotic shuttle systems deliver superior long-term ROI by significantly increasing storage density, picking accuracy, and operational efficiency, reducing labor costs substantially. Warehouses with high throughput and space constraints benefit more from robotic shuttle systems despite the higher capital expenditure.

Flexibility and Adaptability in Inventory Management

Pallet racking systems offer structured, high-density storage ideal for standardized inventory but lack dynamic adaptability for varying product sizes or rapid layout changes. Robotic shuttle systems provide superior flexibility by autonomously navigating aisles and adjusting storage locations in real-time, optimizing space utilization and accommodating diverse inventory profiles. This adaptability enhances inventory management efficiency, enabling swift responses to fluctuating demand and complex SKU assortments.

Maintenance Requirements and System Downtime

Pallet racking systems require minimal maintenance, primarily involving periodic inspections for structural integrity and bolt tightening, resulting in low system downtime. In contrast, robotic shuttle systems demand regular software updates, battery replacements, and mechanical servicing, leading to higher maintenance complexity and potential operational interruptions. Effective maintenance planning for robotic shuttles is critical to minimizing downtime and ensuring continuous warehouse productivity.

Safety Considerations in Automated vs Manual Systems

Automated Robotic Shuttle Systems significantly reduce safety risks by minimizing human interaction with heavy loads and high racks, leading to fewer workplace injuries compared to manual pallet racking operations. Pallet racking relies heavily on forklift operators, increasing the potential for accidents due to human error, such as collisions and improper load handling. Implementing advanced safety sensors and automated controls in robotic systems further enhances hazard detection and emergency response, ensuring a safer warehouse environment.

Choosing the Right Solution for Your Warehouse

Pallet racking offers a cost-effective and scalable storage solution ideal for warehouses with predictable inventory turnover and easy manual access. Robotic shuttle systems enhance automation by maximizing space utilization and speeding up retrieval in high-density, fast-moving environments. Selecting the right system depends on factors such as inventory type, throughput requirements, warehouse size, and budget constraints to optimize operational efficiency.

Related Important Terms

Dynamic Racking Integration

Pallet racking systems provide structured, high-density storage with easy accessibility, while robotic shuttle systems enhance dynamic racking integration by automating load handling and retrieval, significantly increasing throughput and space utilization. Combining robotic shuttles with traditional pallet racks optimizes inventory management, reducing operational costs and improving warehouse efficiency.

Automated Storage and Retrieval Systems (ASRS)

Automated Storage and Retrieval Systems (ASRS) offer significant efficiency advantages in warehousing by combining precision robotics with optimized storage density, where robotic shuttle systems excel in dynamic retrieval speed and scalability compared to traditional pallet racking. Robotic shuttle ASRS enhance inventory accuracy and throughput by automating material handling processes, reducing labor costs, and maximizing space utilization in high-density storage environments.

Deep Lane Storage

Deep lane storage in pallet racking optimizes vertical space but often limits accessibility due to fixed aisle configurations, leading to longer retrieval times. In contrast, robotic shuttle systems enable dynamic storage with automated shuttles navigating deep lanes, significantly improving pick efficiency and maximizing storage density.

Multi-Shuttle Robots

Multi-shuttle robots in robotic shuttle systems offer high-density storage and rapid retrieval, outperforming traditional pallet racking in space utilization and operational efficiency. These automated systems enhance inventory accuracy and reduce labor costs by dynamically managing multi-level storage with precision and speed in complex warehouse environments.

Shuttle-Based Pallet Handling

Shuttle-based pallet handling systems offer increased throughput and space utilization compared to traditional pallet racking by automating pallet storage and retrieval with robotic shuttles navigating within dense rack structures. This technology enhances warehouse efficiency through precise inventory management, faster order fulfillment, and reduced labor costs, making it ideal for high-volume, fast-moving inventory environments.

High-Density Racking

High-density pallet racking maximizes vertical storage space by stacking pallets closely to optimize warehouse footprint, while robotic shuttle systems enhance space utilization by automating the storage and retrieval process within compact aisles. Robotic shuttles offer increased throughput and reduced labor costs, making them ideal for warehouses requiring scalable and efficient high-density storage solutions.

Goods-to-Person Technology

Goods-to-Person technology in warehouse fulfillment dramatically increases picking efficiency by using Pallet Racking for high-density static storage, while Robotic Shuttle Systems optimize dynamic storage and retrieval through autonomous shuttles navigating storage aisles. Robotic Shuttle Systems reduce labor costs and improve throughput by delivering inventory directly to operators, contrasting with traditional Pallet Racking's dependency on manual picker movement.

Millimeter-Level Positioning

Pallet racking systems rely on fixed shelving requiring manual handling, which can limit efficiency in high-density storage environments. Robotic shuttle systems utilize millimeter-level positioning technology, enabling precise automation that maximizes space utilization and accelerates order fulfillment accuracy in warehouses.

Pallet Live Storage

Pallet Live Storage maximizes space by using gravity rollers to enable first-in, first-out inventory flow, increasing efficiency in high-turnover warehouses. Compared to Robotic Shuttle Systems, it offers a cost-effective solution with reduced mechanical complexity, ideal for facilities prioritizing swift pallet retrieval and density over automation.

Racking Digital Twin

Racking digital twin technology enables real-time simulation and optimization of pallet racking layouts, improving space utilization and operational efficiency in warehouses. Compared to robotic shuttle systems, digital twins provide detailed virtual replicas that facilitate predictive maintenance, capacity planning, and workflow analysis without disrupting physical operations.

Pallet Racking vs Robotic Shuttle System Infographic

industrydif.com

industrydif.com