Cold storage warehouses specialize in preserving perishable goods at controlled low temperatures, ensuring product freshness and extending shelf life. Micro-fulfillment centers prioritize rapid order processing and efficient inventory management in smaller urban spaces, supporting quick delivery of e-commerce orders. Both solutions address specific logistical challenges, with cold storage focusing on product preservation and micro-fulfillment enhancing last-mile distribution speed.

Table of Comparison

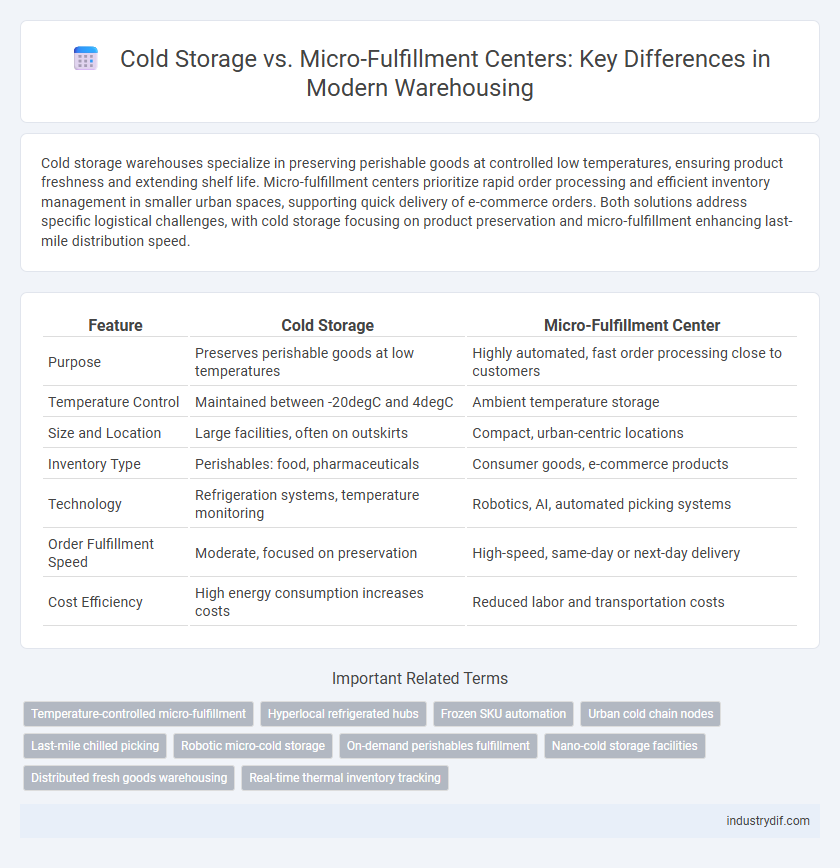

| Feature | Cold Storage | Micro-Fulfillment Center |

|---|---|---|

| Purpose | Preserves perishable goods at low temperatures | Highly automated, fast order processing close to customers |

| Temperature Control | Maintained between -20degC and 4degC | Ambient temperature storage |

| Size and Location | Large facilities, often on outskirts | Compact, urban-centric locations |

| Inventory Type | Perishables: food, pharmaceuticals | Consumer goods, e-commerce products |

| Technology | Refrigeration systems, temperature monitoring | Robotics, AI, automated picking systems |

| Order Fulfillment Speed | Moderate, focused on preservation | High-speed, same-day or next-day delivery |

| Cost Efficiency | High energy consumption increases costs | Reduced labor and transportation costs |

Introduction to Cold Storage and Micro-Fulfillment Centers

Cold storage facilities specialize in preserving perishable goods by maintaining controlled low temperatures, ensuring product freshness and extending shelf life in warehousing operations. Micro-fulfillment centers utilize automated systems and strategic urban locations to expedite order fulfillment by minimizing delivery times and optimizing last-mile logistics. Both cold storage and micro-fulfillment centers address distinct supply chain challenges through temperature control and rapid processing, respectively.

Key Differences Between Cold Storage and Micro-Fulfillment

Cold storage facilities maintain strictly controlled low temperatures to preserve perishable goods like food and pharmaceuticals, relying on refrigeration technology and insulated environments. Micro-fulfillment centers emphasize rapid order processing and automated inventory handling within urban areas to enable same-day delivery for e-commerce and retail sectors. The key differences lie in temperature control requirements, spatial design optimized for speed versus preservation, and the specific types of inventory management systems tailored to either perishable goods or high-velocity consumer products.

Temperature Control and Product Handling Requirements

Cold storage facilities maintain strict temperature control ranging from -25degC to 5degC to preserve perishable goods such as frozen foods and pharmaceuticals, ensuring product integrity through advanced refrigeration and humidity management systems. Micro-fulfillment centers, optimized for rapid order processing of e-commerce items, typically operate at ambient temperatures but require precise handling protocols for temperature-sensitive products to avoid spoilage during short-term storage. Both warehousing types implement specialized equipment like insulated packaging and temperature monitoring sensors to meet specific product handling requirements and guarantee safety and quality.

Space Utilization and Facility Footprint

Cold storage warehouses maximize space utilization through vertical stacking and specialized insulation, resulting in a larger facility footprint due to climate control requirements. Micro-fulfillment centers optimize limited urban spaces by employing automated systems and compact layouts, significantly reducing the overall facility footprint. Efficient design in both facilities directly impacts operational costs and scalability within the warehousing sector.

Technology Integration and Automation Solutions

Cold storage facilities employ advanced temperature control systems and automated refrigeration monitoring to maintain product integrity, integrating IoT sensors for real-time data analytics. Micro-fulfillment centers leverage robotics, AI-driven inventory management, and automated picking systems to optimize order accuracy and speed in urban environments. Both systems utilize cloud-based platforms to seamlessly coordinate inventory tracking and operational workflows, enhancing efficiency and reducing human error.

Order Fulfillment Speed and Efficiency

Cold storage warehouses specialize in preserving perishable goods at controlled temperatures, ensuring product quality but often requiring slower handling processes. Micro-fulfillment centers leverage automation and proximity to end consumers, enabling rapid order processing and faster delivery times. The efficiency of micro-fulfillment centers significantly accelerates order fulfillment speed compared to traditional cold storage facilities, which prioritize long-term storage over immediate dispatch.

Scalability and Flexibility in Operations

Cold storage warehouses prioritize temperature-controlled environments essential for perishable goods, offering limited scalability due to specialized infrastructure and high energy costs. Micro-fulfillment centers emphasize operational flexibility with modular designs that quickly adapt to fluctuating demand and diverse product ranges, enabling scalable solutions within urban settings. Efficient scalability and flexibility in operations are critical for optimizing inventory management and meeting dynamic consumer demands in both warehousing models.

Cost Considerations and Investment Factors

Cold storage facilities demand significant investment in refrigeration technology, energy consumption, and specialized infrastructure, leading to higher operating costs compared to micro-fulfillment centers. Micro-fulfillment centers typically require less space and lower initial capital expenditure, leveraging automation to reduce labor costs and improve order processing speed. Evaluating the balance between energy expenses in cold storage and automation investments in micro-fulfillment helps businesses optimize cost efficiency based on product type and demand patterns.

Industry Applications and Use Cases

Cold storage facilities are essential for preserving perishable goods in the food and pharmaceutical industries, maintaining strict temperature control to extend product shelf life. Micro-fulfillment centers, designed for rapid order processing and last-mile delivery, serve e-commerce, retail, and grocery sectors by enhancing efficiency and reducing delivery times. Both solutions address specific industry needs: cold storage supports supply chain integrity for temperature-sensitive products, while micro-fulfillment centers optimize inventory management and customer service in urban markets.

Future Trends in Warehousing: Cold Storage vs. Micro-Fulfillment

Cold storage warehouses are evolving with advanced temperature control technologies and automation to meet growing demands for perishable goods, enhancing energy efficiency and reducing spoilage. Micro-fulfillment centers leverage AI-driven robotics and real-time inventory management to accelerate last-mile delivery, supporting e-commerce growth and urban retail strategies. Emerging hybrid models combining cold storage capabilities with micro-fulfillment technologies indicate a shift toward highly adaptive, space-efficient warehousing solutions in the future.

Related Important Terms

Temperature-controlled micro-fulfillment

Temperature-controlled micro-fulfillment centers optimize cold storage by integrating advanced refrigeration technologies with automated picking systems, enabling efficient handling of perishable goods in urban warehouse settings. This approach reduces transit times, enhances product freshness, and supports high-volume demand in temperature-sensitive supply chains.

Hyperlocal refrigerated hubs

Hyperlocal refrigerated hubs blend the efficiency of micro-fulfillment centers with specialized cold storage capabilities, enabling rapid delivery of perishable goods within urban areas. These hubs optimize temperature-controlled inventory management and reduce last-mile delivery times, enhancing freshness and customer satisfaction in hyperlocal supply chains.

Frozen SKU automation

Cold storage facilities specialize in automated frozen SKU handling with temperature-controlled environments that preserve product integrity, while micro-fulfillment centers emphasize rapid order processing and localized distribution, integrating automation primarily for inventory picking rather than long-term frozen storage. Advanced robotics and automated retrieval systems in cold storage optimize frozen SKU management by minimizing human contact and temperature fluctuations, contrasting with micro-fulfillment centers that prioritize speed and efficiency in high-demand order fulfillment for fresh or ambient goods.

Urban cold chain nodes

Urban cold chain nodes leverage cold storage facilities to maintain temperature-sensitive inventory, ensuring freshness and regulatory compliance in densely populated areas. Micro-fulfillment centers near consumer hubs optimize rapid order processing and delivery speed, integrating cold storage capabilities to support perishable goods in last-mile logistics.

Last-mile chilled picking

Cold storage facilities provide temperature-controlled environments essential for preserving perishable goods, while micro-fulfillment centers prioritize ultra-fast, efficient last-mile chilled picking through automated systems located closer to urban consumers. Integrating real-time inventory management and precise temperature controls enhances freshness and reduces delivery times in cold chain logistics for e-grocery and pharmaceutical distribution.

Robotic micro-cold storage

Robotic micro-cold storage integrates advanced automation within compact micro-fulfillment centers, optimizing temperature-controlled inventory management by enhancing picking speed and accuracy for perishable goods. This technology reduces energy consumption and operational costs compared to traditional cold storage warehouses, enabling efficient last-mile delivery in urban environments.

On-demand perishables fulfillment

Cold storage facilities specialize in preserving perishable goods at controlled low temperatures, ensuring product freshness and safety for extended periods. Micro-fulfillment centers prioritize rapid, on-demand order processing, enhancing the speed and efficiency of last-mile delivery for perishables with minimal storage time.

Nano-cold storage facilities

Nano-cold storage facilities revolutionize warehousing by offering compact, temperature-controlled environments ideal for perishable goods and pharmaceuticals, unlike traditional cold storage centers that require large, complex infrastructure. These micro-fulfillment centers enhance supply chain efficiency with faster inventory turnaround and reduced energy consumption, making them optimal for urban settings and last-mile delivery.

Distributed fresh goods warehousing

Cold storage facilities are specialized warehouses designed to maintain perishable goods at controlled low temperatures, ensuring product freshness and extending shelf life, while micro-fulfillment centers focus on rapid order processing and decentralized inventory distribution within urban areas to reduce delivery times. Distributed fresh goods warehousing combines the temperature control advantages of cold storage with the strategic location benefits of micro-fulfillment centers, optimizing fresh product availability and enhancing supply chain agility for perishable items.

Real-time thermal inventory tracking

Cold storage facilities employ advanced real-time thermal inventory tracking systems to monitor temperature-sensitive products, ensuring optimal freshness and regulatory compliance. Micro-fulfillment centers integrate thermal sensors with automated inventory management to rapidly adjust storage conditions, enhancing efficiency in last-mile delivery of perishable goods.

Cold storage vs Micro-fulfillment center Infographic

industrydif.com

industrydif.com