A Warehouse Management System (WMS) streamlines inventory control, order processing, and labor management through real-time data tracking and automated workflows. In contrast, a Digital Twin creates a virtual replica of the warehouse environment, enabling predictive analytics and simulation for optimized space utilization and process improvements. Combining WMS with Digital Twin technology enhances decision-making by merging operational data with dynamic modeling, leading to increased efficiency and reduced operational costs.

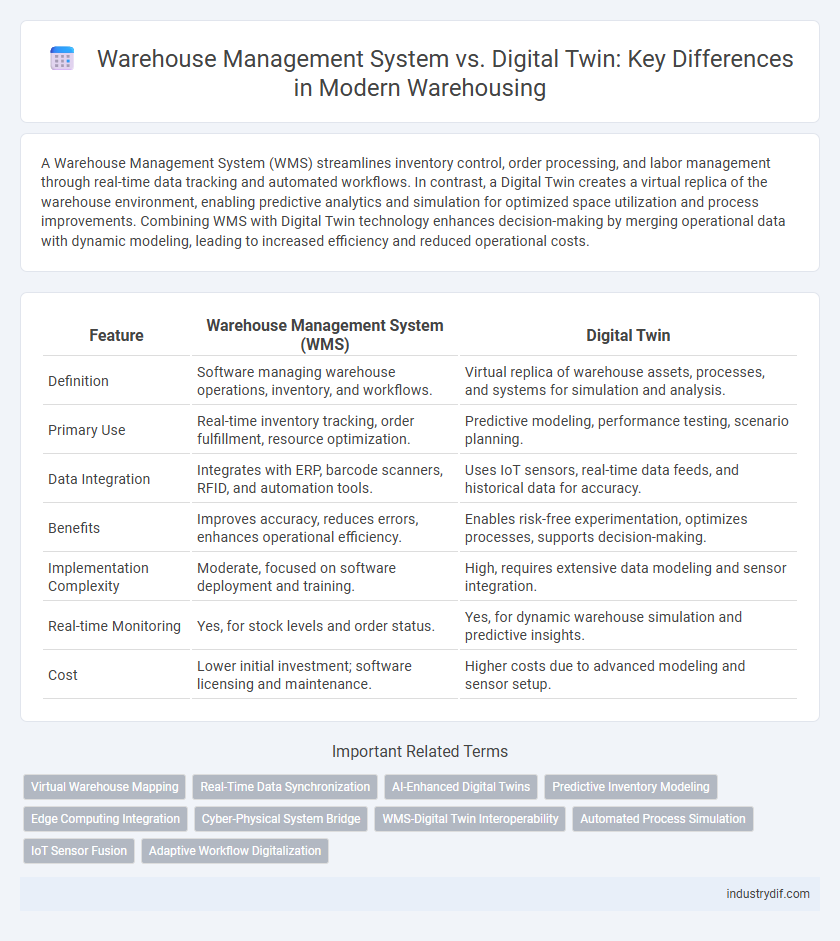

Table of Comparison

| Feature | Warehouse Management System (WMS) | Digital Twin |

|---|---|---|

| Definition | Software managing warehouse operations, inventory, and workflows. | Virtual replica of warehouse assets, processes, and systems for simulation and analysis. |

| Primary Use | Real-time inventory tracking, order fulfillment, resource optimization. | Predictive modeling, performance testing, scenario planning. |

| Data Integration | Integrates with ERP, barcode scanners, RFID, and automation tools. | Uses IoT sensors, real-time data feeds, and historical data for accuracy. |

| Benefits | Improves accuracy, reduces errors, enhances operational efficiency. | Enables risk-free experimentation, optimizes processes, supports decision-making. |

| Implementation Complexity | Moderate, focused on software deployment and training. | High, requires extensive data modeling and sensor integration. |

| Real-time Monitoring | Yes, for stock levels and order status. | Yes, for dynamic warehouse simulation and predictive insights. |

| Cost | Lower initial investment; software licensing and maintenance. | Higher costs due to advanced modeling and sensor setup. |

Introduction to Warehouse Management Systems (WMS)

Warehouse Management Systems (WMS) streamline inventory control, order fulfillment, and real-time tracking within distribution centers, optimizing warehouse operations and boosting efficiency. These systems integrate with automated technologies such as barcode scanning and RFID to enhance accuracy and reduce human error. WMS platforms provide critical analytics and reporting features that support data-driven decision-making in warehouse management.

Understanding Digital Twins in Warehousing

Digital Twin technology in warehousing creates a real-time virtual replica of warehouse operations, enabling precise monitoring and simulation of inventory flow, equipment usage, and spatial layout. Unlike traditional Warehouse Management Systems (WMS) that focus on task execution and data tracking, Digital Twins provide dynamic performance analytics and predictive insights to optimize workflow and resource allocation. Integrating Digital Twin models with IoT sensors delivers actionable intelligence, enhancing decision-making for inventory management, order fulfillment, and facility maintenance.

Core Features of Warehouse Management Systems

Warehouse Management Systems (WMS) excel in inventory tracking, order fulfillment, and real-time data accuracy, optimizing warehouse operations through barcode scanning and automated workflows. Core features include slotting optimization, labor management, and shipment scheduling, ensuring efficient resource allocation and reduced operational costs. Unlike digital twins, which simulate warehouse environments, WMS provides actionable execution tools directly impacting day-to-day logistics and inventory control.

Key Components of Digital Twin Technology

Digital Twin technology in warehousing integrates real-time data from IoT sensors, advanced analytics, and simulation models to create a dynamic virtual replica of the physical warehouse environment. Key components include data acquisition systems, high-fidelity 3D modeling, and machine learning algorithms that predict operational outcomes and optimize resource allocation. This technology enables continuous monitoring, scenario testing, and predictive maintenance, surpassing traditional Warehouse Management Systems that primarily focus on inventory control and transaction processing.

Digital Twin vs WMS: Functional Differences

Digital Twin technology offers a virtual replica of physical warehouse operations, enabling real-time simulation, predictive analytics, and scenario testing, whereas a Warehouse Management System (WMS) primarily focuses on inventory control, order processing, and workflow optimization. Unlike WMS, which manages transactional data and execution, Digital Twins provide dynamic visualization and system-wide insights to improve strategic decision-making and operational efficiency. Integrating Digital Twin with WMS enhances proactive issue resolution and continuous process improvement through data-driven modeling of warehouse environments.

Integration Capabilities with Existing Warehouse Infrastructure

Warehouse Management Systems (WMS) offer robust integration capabilities with existing warehouse infrastructure, enabling real-time inventory tracking, order fulfillment, and automation through seamless connectivity with barcode scanners, conveyor systems, and ERP platforms. Digital Twins complement this by creating dynamic simulations of warehouse operations, facilitating predictive maintenance and optimizing workflows without disrupting current systems. Integrating WMS with Digital Twin technology enhances decision-making accuracy and operational efficiency through synchronized data exchange and visualization within the same warehouse ecosystem.

Data Analytics and Real-Time Insights Comparison

Warehouse Management Systems (WMS) primarily offer robust data analytics for inventory tracking, order processing, and labor management, providing structured reports and historical trend analysis. Digital Twins enhance this by delivering real-time insights through dynamic simulation of warehouse operations, enabling predictive analytics and what-if scenario testing for optimized decision-making. Combining WMS data with Digital Twin models results in a comprehensive platform that improves operational efficiency, reduces downtime, and supports proactive management.

Scalability and Flexibility in Warehouse Operations

Warehouse Management Systems (WMS) offer streamlined scalability by automating inventory control and order processing, enabling warehouses to efficiently manage increasing volumes. Digital Twin technology enhances flexibility through real-time simulation and predictive analytics, allowing warehouses to adapt layouts and workflows dynamically in response to changing operational demands. Integrating both systems provides a comprehensive approach to scaling operations while maintaining agility in complex warehouse environments.

Cost-Benefit Analysis: WMS vs Digital Twin

A Warehouse Management System (WMS) offers cost-effective inventory control and operational efficiency with a relatively lower initial investment and faster implementation compared to a Digital Twin. In contrast, Digital Twin technology, though requiring a higher upfront cost due to advanced sensors and simulation software, delivers long-term benefits by enabling predictive maintenance, real-time optimization, and scenario planning that reduce downtime and improve resource utilization. Evaluating ROI involves balancing WMS's immediate improvements in accuracy and throughput against Digital Twin's ability to drive continuous innovation and strategic warehouse management.

Future Trends in Digital Warehousing Technologies

Warehouse Management Systems (WMS) increasingly integrate with digital twin technology to create dynamic, real-time virtual replicas of physical warehouse operations, enhancing predictive analytics and operational efficiency. Future trends in digital warehousing emphasize AI-driven optimization, IoT integration for real-time data capture, and advanced simulation capabilities within digital twins to streamline inventory management and reduce downtime. This convergence supports smarter decision-making, adaptive logistics, and scalable warehouse automation to meet evolving supply chain demands.

Related Important Terms

Virtual Warehouse Mapping

Warehouse Management Systems (WMS) optimize inventory tracking and operational workflows through real-time data integration, whereas Digital Twins create a virtual replica of the warehouse environment enabling dynamic simulation of space utilization and process optimization. Virtual warehouse mapping within Digital Twins provides detailed 3D visualization and predictive analytics that surpass traditional WMS, enhancing decision-making and efficiency in inventory placement and resource allocation.

Real-Time Data Synchronization

Warehouse Management Systems (WMS) provide structured inventory control and process automation, while Digital Twins offer dynamic, real-time data synchronization by creating a virtual replica of the warehouse environment. Real-time synchronization in Digital Twins enhances decision-making accuracy by continuously updating inventory levels, equipment status, and workflow conditions, surpassing the static data snapshots typical of traditional WMS.

AI-Enhanced Digital Twins

AI-enhanced digital twins in warehousing offer dynamic, real-time simulations of inventory flow, spatial optimization, and operational workflows, surpassing traditional Warehouse Management Systems (WMS) by enabling predictive analytics and proactive decision-making. These intelligent models integrate IoT data and machine learning algorithms to continuously optimize storage layouts, equipment usage, and labor allocation, achieving higher efficiency and reduced operational costs.

Predictive Inventory Modeling

A Warehouse Management System (WMS) primarily tracks real-time inventory levels and optimizes storage and retrieval processes, while a Digital Twin extends capabilities by creating a virtual replica of the entire warehouse environment to simulate and predict future inventory demands and operational scenarios. Predictive inventory modeling using Digital Twins enables more accurate forecasting by analyzing historical data and real-time inputs, leading to enhanced decision-making and reduced stockouts or overstock situations.

Edge Computing Integration

Warehouse Management Systems (WMS) integrated with edge computing enable real-time inventory tracking and operational efficiency by processing data locally at the warehouse site, reducing latency and reliance on cloud connectivity. In contrast, digital twins leverage edge computing to create dynamic virtual models of warehouse environments, facilitating advanced simulations and predictive maintenance for enhanced decision-making and resource optimization.

Cyber-Physical System Bridge

Warehouse Management Systems (WMS) optimize inventory control and operational workflows by providing real-time data, whereas Digital Twins create a dynamic, virtual replica of the warehouse environment for advanced simulations and predictive analysis. The Cyber-Physical System Bridge integrates these technologies, enabling seamless data exchange and enhanced decision-making through synchronized physical assets and their digital counterparts.

WMS-Digital Twin Interoperability

Warehouse Management System (WMS) enhances operational efficiency by optimizing inventory tracking and order fulfillment, while Digital Twin technology provides real-time simulation and predictive insights by mirroring physical warehouse environments. Integrating WMS with Digital Twin enables seamless data exchange, resulting in improved decision-making accuracy, dynamic process adjustments, and enhanced resource utilization within warehousing operations.

Automated Process Simulation

Warehouse Management Systems (WMS) optimize inventory control and order fulfillment through real-time data tracking while Digital Twins provide automated process simulation by creating virtual replicas of warehouse operations to predict performance and identify bottlenecks. Integrating Digital Twin technology with WMS enables enhanced decision-making by simulating scenarios and optimizing layout, resource allocation, and workflow efficiency.

IoT Sensor Fusion

Warehouse Management Systems optimize inventory control through real-time data integration, while Digital Twins leverage IoT sensor fusion to create dynamic, virtual replicas of warehouse environments for enhanced operational simulation and predictive analytics. IoT sensor fusion combines data from RFID, temperature sensors, and motion detectors, enabling both systems to improve accuracy in asset tracking, environmental monitoring, and workflow automation.

Adaptive Workflow Digitalization

Warehouse Management Systems (WMS) optimize inventory control and order fulfillment through predefined processes, while Digital Twins enable adaptive workflow digitalization by creating real-time virtual replicas of warehouse operations for dynamic response and predictive analytics. Integrating Digital Twins with WMS enhances flexibility, allowing continuous process adjustments based on live data and improving overall operational efficiency.

Warehouse Management System vs Digital Twin Infographic

industrydif.com

industrydif.com