Cross-docking minimizes storage time by directly transferring incoming shipments to outbound vehicles, accelerating order fulfillment and reducing inventory costs. Flow-through fulfillment integrates inventory storage with order processing within the warehouse, offering flexibility to handle both stocked and incoming goods efficiently. Choosing between cross-docking and flow-through fulfillment depends on factors like order volume, product variety, and delivery timelines to optimize warehouse operations.

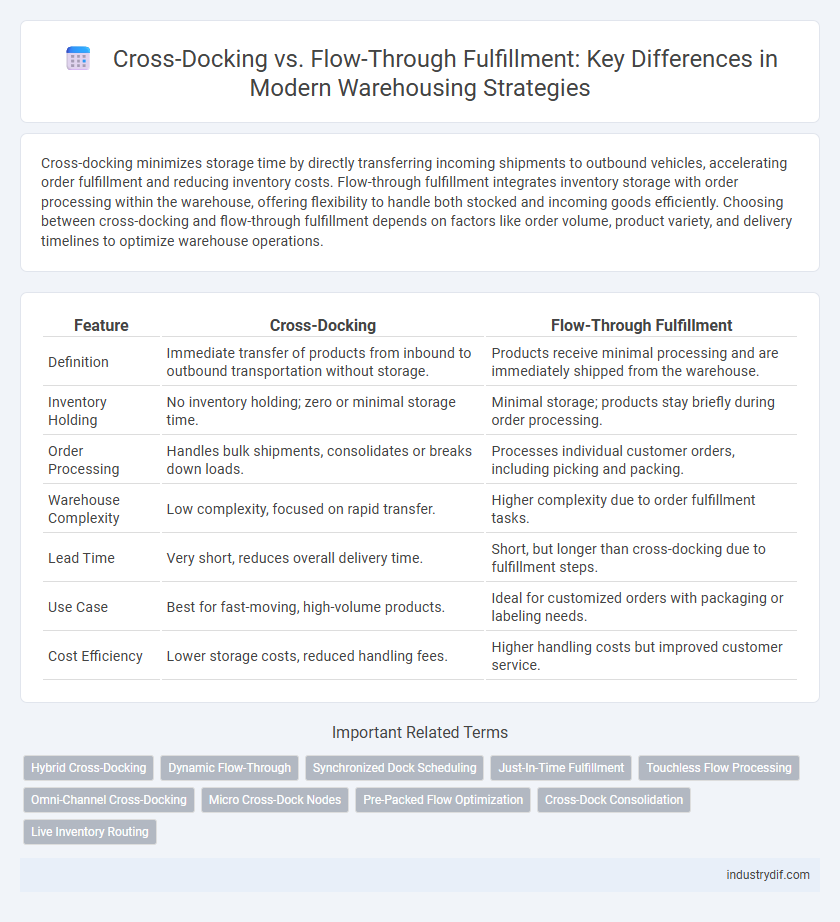

Table of Comparison

| Feature | Cross-Docking | Flow-Through Fulfillment |

|---|---|---|

| Definition | Immediate transfer of products from inbound to outbound transportation without storage. | Products receive minimal processing and are immediately shipped from the warehouse. |

| Inventory Holding | No inventory holding; zero or minimal storage time. | Minimal storage; products stay briefly during order processing. |

| Order Processing | Handles bulk shipments, consolidates or breaks down loads. | Processes individual customer orders, including picking and packing. |

| Warehouse Complexity | Low complexity, focused on rapid transfer. | Higher complexity due to order fulfillment tasks. |

| Lead Time | Very short, reduces overall delivery time. | Short, but longer than cross-docking due to fulfillment steps. |

| Use Case | Best for fast-moving, high-volume products. | Ideal for customized orders with packaging or labeling needs. |

| Cost Efficiency | Lower storage costs, reduced handling fees. | Higher handling costs but improved customer service. |

Introduction to Cross-Docking and Flow-Through Fulfillment

Cross-docking streamlines warehousing by directly transferring inbound shipments to outbound transportation without long-term storage, significantly reducing handling and storage costs. Flow-through fulfillment integrates cross-docking with minimal inventory holding, allowing fast processing of orders by routing products directly from receiving to shipping. Both methods enhance supply chain efficiency through expedited order fulfillment and minimized inventory dwell time.

Defining Cross-Docking in Modern Warehousing

Cross-docking in modern warehousing is a logistics technique where incoming shipments are directly transferred to outbound transportation with minimal or no storage time. This method reduces inventory holding costs, accelerates order fulfillment, and optimizes supply chain efficiency by streamlining product flow through distribution centers. Advanced warehouse management systems (WMS) and real-time data integration enhance the precision and speed of cross-docking operations.

Understanding Flow-Through Fulfillment Processes

Flow-through fulfillment streamlines order processing by bypassing traditional storage and directly moving incoming goods to outbound shipping. This method reduces inventory handling time and minimizes storage costs, enhancing supply chain efficiency. Integrating real-time data tracking optimizes flow-through operations, ensuring swift and accurate order fulfillment within a warehouse environment.

Key Differences Between Cross-Docking and Flow-Through

Cross-docking minimizes storage time by directly transferring inbound goods to outbound vehicles, reducing inventory holding costs and improving delivery speed. Flow-through fulfillment integrates receiving, quality inspection, and order picking within the warehouse, allowing faster dispatch of stocked items while maintaining inventory control. Key differences include cross-docking's zero storage approach versus flow-through's partial storage and processing, impacting operational complexity and inventory management strategies.

Operational Workflow Comparison

Cross-docking streamlines operational workflow by transferring inbound shipments directly to outbound trucks, minimizing storage time and reducing handling costs. Flow-through fulfillment involves receiving products, briefly storing or sorting them, then picking and packing orders for shipment, which allows for greater customization and order accuracy. Understanding these workflows helps warehouses optimize throughput, reduce lead times, and improve inventory management efficiency.

Advantages of Cross-Docking

Cross-docking significantly reduces inventory holding costs by minimizing storage time, ensuring faster product turnover in warehouses. It enhances supply chain efficiency through direct transfer of goods from inbound to outbound transportation, reducing handling and potential damage. This method improves delivery speed and accuracy, supporting just-in-time inventory systems and boosting customer satisfaction in e-commerce and retail operations.

Benefits of Flow-Through Fulfillment

Flow-through fulfillment reduces storage costs by minimizing inventory holding time and streamlining order processing directly from receiving to shipping. This method enhances order accuracy and speeds up delivery, improving customer satisfaction through faster turnaround times. Increased operational efficiency and lower labor expenses result from the elimination of multiple handling stages inherent in traditional warehousing.

Challenges in Implementation

Cross-docking faces challenges such as synchronizing inbound and outbound shipments to minimize storage time and reduce bottlenecks, requiring precise coordination and real-time communication systems. Flow-through fulfillment struggles with demand variability and inventory accuracy, as it relies on efficient processing directly from receiving to shipping without traditional storage buffers. Both methods demand advanced warehouse management systems (WMS) and staff training to handle complex workflows and maintain operational efficiency.

Choosing the Right Fulfillment Strategy

Selecting the appropriate fulfillment strategy hinges on analyzing order volume, product types, and delivery speed requirements. Cross-docking minimizes storage time by directly transferring inbound shipments to outbound carriers, ideal for perishable goods and high-turnover inventory. Flow-through fulfillment combines receiving and shipping operations within the warehouse, suitable for mixed product assortments and orders requiring value-added services like customization or kitting.

Future Trends in Warehouse Fulfillment Models

Future trends in warehouse fulfillment models emphasize the integration of cross-docking and flow-through fulfillment to optimize inventory turnover and reduce delivery lead times. Advanced automation technologies and real-time data analytics enable seamless transitions between inbound and outbound shipments, enhancing supply chain agility. Adoption of AI-driven sorting and predictive demand forecasting will further refine efficiency, meeting the rising demand for rapid e-commerce deliveries.

Related Important Terms

Hybrid Cross-Docking

Hybrid Cross-Docking combines elements of Cross-Docking and Flow-Through Fulfillment to maximize efficiency by minimizing inventory holding and reducing order processing time, enabling faster delivery cycles and lowered operational costs. This method seamlessly integrates real-time inventory transfers with value-added services, optimizing supply chain responsiveness and improving overall warehouse throughput.

Dynamic Flow-Through

Dynamic Flow-Through fulfillment enhances traditional cross-docking by enabling real-time inventory routing and order prioritization, reducing handling time and improving order accuracy in high-volume warehouses. Its adaptive system integrates seamlessly with warehouse management software, optimizing the flow of goods from receiving to shipping without long-term storage.

Synchronized Dock Scheduling

Synchronized dock scheduling in cross-docking minimizes storage time by coordinating inbound and outbound shipments precisely, enabling seamless transfer of goods directly from receiving to shipping docks. In contrast, flow-through fulfillment uses synchronized schedules to streamline sorting and packing processes within the warehouse, enhancing efficiency but still involving some inventory staging.

Just-In-Time Fulfillment

Cross-docking optimizes Just-In-Time fulfillment by minimizing inventory holding and accelerating product movement directly from receiving to shipping docks, reducing lead times and storage costs. Flow-through fulfillment integrates order processing with receiving, enabling faster response to customer demands while balancing inventory levels for efficient just-in-time operations.

Touchless Flow Processing

Touchless flow processing in warehousing enhances both cross-docking and flow-through fulfillment by minimizing manual handling and accelerating product movement directly from receiving to shipping. This streamlined approach reduces labor costs and errors while improving order accuracy and delivery speed for high-volume distribution centers.

Omni-Channel Cross-Docking

Omni-Channel Cross-Docking streamlines inventory flow by directly transferring products from inbound to outbound shipments without storage, reducing handling time and costs while improving order accuracy. Compared to Flow-Through Fulfillment, which temporarily holds inventory for order consolidation, Omni-Channel Cross-Docking enhances real-time responsiveness and supports seamless multi-channel order fulfillment across retail, e-commerce, and distribution centers.

Micro Cross-Dock Nodes

Micro cross-dock nodes streamline warehousing by enabling rapid transfer of goods between inbound and outbound shipments, minimizing storage time and increasing throughput efficiency. Compared to traditional flow-through fulfillment, these nodes reduce handling costs and improve delivery speed by concentrating inventory consolidation and order picking in localized, smaller-scale facilities.

Pre-Packed Flow Optimization

Cross-Docking minimizes inventory holding by transferring pre-packed goods directly from inbound to outbound transportation, streamlining flow-through fulfillment processes. Pre-packed flow optimization enhances warehouse efficiency by reducing handling time and accelerating order accuracy in high-volume distribution environments.

Cross-Dock Consolidation

Cross-dock consolidation streamlines inventory management by directly transferring goods from inbound to outbound transportation with minimal storage time, significantly reducing handling and storage costs. This method enhances shipment accuracy and speeds up delivery compared to flow-through fulfillment, which involves temporary storage and additional picking processes.

Live Inventory Routing

Live inventory routing optimizes order fulfillment by dynamically directing products from suppliers to customers without long-term storage, enhancing cross-docking efficiency. Flow-through fulfillment processes live inventory by immediately shipping inbound goods to outbound orders, reducing handling time and inventory holding costs compared to traditional warehousing.

Cross-Docking vs Flow-Through Fulfillment Infographic

industrydif.com

industrydif.com