Traditional warehouses rely on manual inventory tracking and fixed storage systems, often leading to inefficiencies and limited scalability. Cloud-managed warehouses leverage real-time data analytics and automation to optimize inventory management, streamline operations, and enhance flexibility. This technology-driven approach reduces operational costs and improves supply chain responsiveness compared to conventional methods.

Table of Comparison

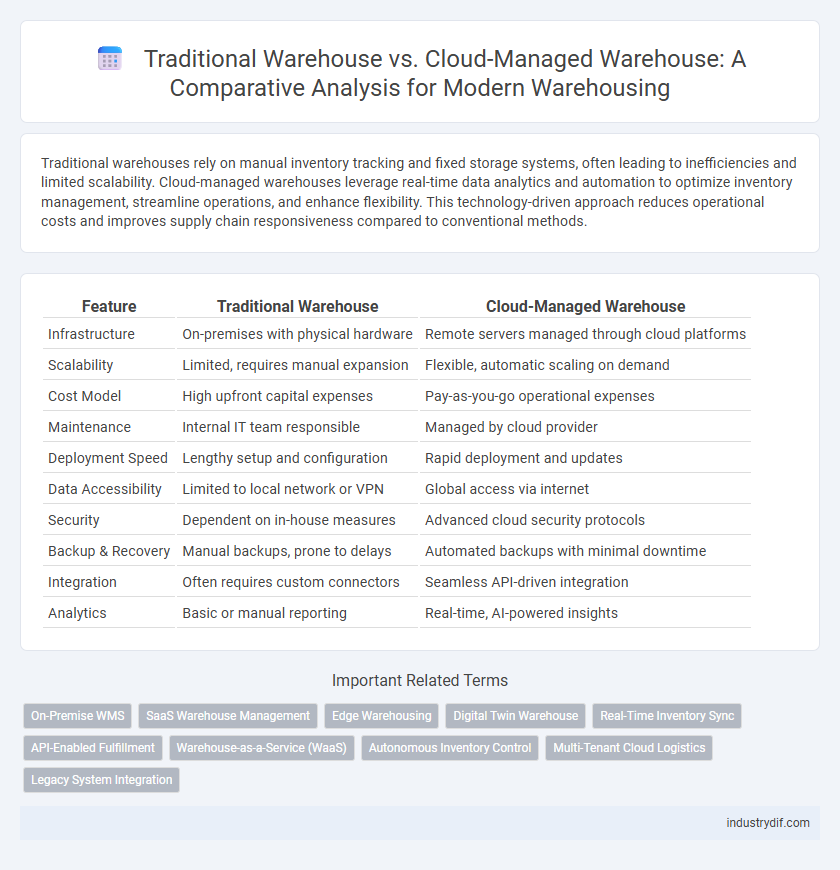

| Feature | Traditional Warehouse | Cloud-Managed Warehouse |

|---|---|---|

| Infrastructure | On-premises with physical hardware | Remote servers managed through cloud platforms |

| Scalability | Limited, requires manual expansion | Flexible, automatic scaling on demand |

| Cost Model | High upfront capital expenses | Pay-as-you-go operational expenses |

| Maintenance | Internal IT team responsible | Managed by cloud provider |

| Deployment Speed | Lengthy setup and configuration | Rapid deployment and updates |

| Data Accessibility | Limited to local network or VPN | Global access via internet |

| Security | Dependent on in-house measures | Advanced cloud security protocols |

| Backup & Recovery | Manual backups, prone to delays | Automated backups with minimal downtime |

| Integration | Often requires custom connectors | Seamless API-driven integration |

| Analytics | Basic or manual reporting | Real-time, AI-powered insights |

Introduction to Warehousing Models

Traditional warehouses rely on physical infrastructure and on-premise management systems to store and organize inventory, often requiring significant capital investment and manual processes. Cloud-managed warehouses utilize cloud computing technology to enable real-time data access, scalable storage solutions, and automated inventory management, enhancing operational efficiency and adaptability. Integrating Internet of Things (IoT) devices and big data analytics in cloud-managed models transforms traditional warehousing into dynamic, data-driven ecosystems.

Defining Traditional Warehouse Management

Traditional warehouse management relies on manual processes and on-premise systems to track inventory, coordinate shipments, and manage storage. It typically involves physical paperwork, barcode scanning, and localized database management, which can lead to slower data access and higher error rates. This approach limits scalability and real-time visibility compared to modern cloud-managed warehouse solutions.

Overview of Cloud-Managed Warehouse Solutions

Cloud-managed warehouse solutions offer real-time inventory visibility and automated workflows, improving accuracy and efficiency compared to traditional warehouses. These platforms use IoT devices and cloud computing to enable seamless data synchronization across multiple locations. Enhanced scalability and remote management capabilities make cloud-based warehouses ideal for modern supply chain demands.

Key Differences Between Traditional and Cloud Warehousing

Traditional warehouses rely on physical infrastructure and manual inventory management, limiting scalability and real-time data access. Cloud-managed warehouses utilize digital platforms and automation, enabling centralized control, dynamic resource allocation, and seamless integration with supply chain systems. Key differences include cost efficiency, flexibility, and enhanced data analytics capabilities in cloud-managed solutions compared to traditional warehousing.

Scalability and Flexibility in Warehouse Operations

Traditional warehouses often face limitations in scalability due to fixed physical space and static infrastructure, restricting their ability to adapt quickly to fluctuating demand. Cloud-managed warehouses leverage scalable cloud computing resources, enabling dynamic adjustment of storage and processing capacity in real-time. Enhanced flexibility in cloud solutions allows seamless integration of automated technologies and data analytics, optimizing warehouse operations and reducing downtime.

Implementation Costs and ROI Comparison

Traditional warehouse implementation costs are typically high due to expenses for physical infrastructure, hardware, and ongoing maintenance, leading to longer ROI periods. Cloud-managed warehouses reduce upfront capital expenditure by leveraging virtual infrastructure, enabling scalable storage and compute resources that optimize operational costs and accelerate ROI. The pay-as-you-go model in cloud warehouses enhances financial flexibility, often resulting in higher cost efficiency and faster realization of returns compared to traditional setups.

Data Integration and Real-Time Visibility

Traditional warehouses often rely on manual data integration processes, leading to delays and potential errors in inventory management. Cloud-managed warehouses leverage advanced APIs and IoT connectivity to enable seamless data integration from multiple sources, ensuring accurate and up-to-date inventory records. Real-time visibility in cloud-managed systems enhances decision-making by providing instant access to stock levels, shipment status, and demand forecasts, optimizing overall warehouse efficiency.

Security and Compliance Considerations

Traditional warehouses often struggle with limited scalability in security protocols and slower compliance updates, relying heavily on manual audits and physical controls. Cloud-managed warehouses leverage advanced encryption, continuous monitoring, and automated compliance frameworks, ensuring real-time adherence to industry standards such as ISO 27001 and GDPR. This modern approach reduces risks related to data breaches and regulatory fines by providing robust, scalable security solutions and immediate vulnerability assessments.

Impact on Supply Chain Efficiency

Traditional warehouses often encounter delays due to manual inventory tracking, limited scalability, and slower data processing, which can disrupt supply chain efficiency. Cloud-managed warehouses leverage real-time data analytics, automated inventory management, and seamless integration with other systems, accelerating decision-making and reducing operational bottlenecks. Enhanced visibility and responsiveness enabled by cloud solutions significantly optimize supply chain workflows and minimize fulfillment times.

Future Trends in Warehouse Management

Traditional warehouses rely heavily on manual inventory tracking and fixed storage systems, limiting scalability and agility in meeting dynamic supply chain demands. Cloud-managed warehouses leverage real-time data analytics, IoT integration, and AI-driven automation to optimize inventory control, enhance order accuracy, and enable predictive maintenance. Emerging trends highlight increased adoption of edge computing, robotics, and seamless cloud connectivity to drive efficiency, cost reduction, and adaptability in future warehouse management systems.

Related Important Terms

On-Premise WMS

On-premise Warehouse Management Systems (WMS) offer direct control over data security and customization but require significant upfront investment and ongoing IT maintenance. In contrast, cloud-managed warehouses provide scalable storage and real-time analytics with lower operational costs, though they depend heavily on internet connectivity and third-party providers.

SaaS Warehouse Management

Traditional warehouses rely on physical infrastructure and manual processes, leading to higher operational costs and limited scalability. Cloud-managed warehouse solutions with SaaS Warehouse Management Systems enable real-time inventory tracking, seamless integration with supply chain tools, and enhanced data analytics for optimized warehouse efficiency.

Edge Warehousing

Traditional warehouses rely on centralized inventory storage with limited real-time data integration, leading to slower order fulfillment and higher transportation costs. Cloud-managed warehouses utilize edge warehousing technology to process data locally at distribution points, enabling faster inventory updates, improved scalability, and enhanced responsiveness to dynamic supply chain demands.

Digital Twin Warehouse

Traditional warehouses rely on physical inventory management systems with limited real-time monitoring, whereas cloud-managed warehouses leverage digital twin technology to create virtual replicas that enable real-time data synchronization, predictive analytics, and enhanced operational efficiency. This integration of digital twin warehouses improves inventory accuracy, reduces downtime, and optimizes supply chain workflows through advanced simulation and data-driven decision-making.

Real-Time Inventory Sync

Traditional warehouses often rely on manual updates and batch processing for inventory management, leading to delayed data synchronization and potential stock discrepancies. Cloud-managed warehouses utilize real-time inventory syncing through integrated IoT devices and cloud software, enabling instant updates, improved accuracy, and efficient stock control across multiple locations.

API-Enabled Fulfillment

Traditional warehouses rely on manual inventory tracking and limited integration capabilities, resulting in slower order processing and higher error rates. Cloud-managed warehouses leverage API-enabled fulfillment to automate real-time inventory updates, seamless order routing, and scalable operations, enhancing accuracy and accelerating delivery times.

Warehouse-as-a-Service (WaaS)

Warehouse-as-a-Service (WaaS) transforms traditional warehousing by leveraging cloud-managed platforms that enable real-time inventory tracking, scalable storage solutions, and automated resource allocation, significantly enhancing operational efficiency and cost-effectiveness. Unlike traditional warehouses with fixed capacity and manual processes, cloud-based WaaS integrates IoT sensors and AI analytics to optimize space utilization and streamline supply chain management.

Autonomous Inventory Control

Traditional warehouses rely heavily on manual inventory tracking and human intervention, leading to higher error rates and slower response times. Cloud-managed warehouses leverage autonomous inventory control through real-time data analytics and IoT integration, enhancing accuracy, efficiency, and predictive stock management.

Multi-Tenant Cloud Logistics

Traditional warehouses rely on physical storage and manual inventory tracking, limiting scalability and real-time visibility, whereas cloud-managed warehouses leverage multi-tenant cloud logistics platforms to optimize space utilization, enable dynamic resource allocation, and provide real-time data analytics for improved supply chain efficiency. Multi-tenant cloud logistics supports multiple clients on shared infrastructure, reducing operational costs while enhancing collaboration and integration across diverse distribution networks.

Legacy System Integration

Traditional warehouses often face challenges integrating with legacy systems due to rigid infrastructure and limited scalability, leading to data silos and operational inefficiencies. Cloud-managed warehouses provide seamless legacy system integration through flexible APIs and real-time data synchronization, enhancing inventory accuracy and streamlining supply chain processes.

Traditional Warehouse vs Cloud-Managed Warehouse Infographic

industrydif.com

industrydif.com