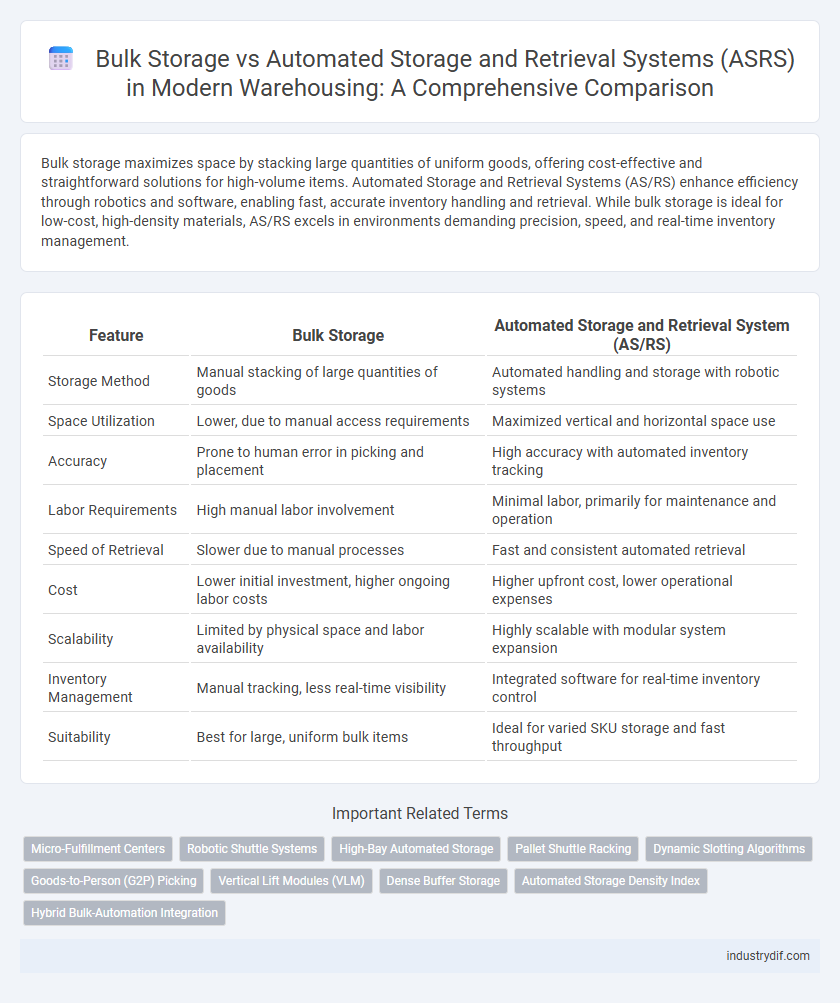

Bulk storage maximizes space by stacking large quantities of uniform goods, offering cost-effective and straightforward solutions for high-volume items. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency through robotics and software, enabling fast, accurate inventory handling and retrieval. While bulk storage is ideal for low-cost, high-density materials, AS/RS excels in environments demanding precision, speed, and real-time inventory management.

Table of Comparison

| Feature | Bulk Storage | Automated Storage and Retrieval System (AS/RS) |

|---|---|---|

| Storage Method | Manual stacking of large quantities of goods | Automated handling and storage with robotic systems |

| Space Utilization | Lower, due to manual access requirements | Maximized vertical and horizontal space use |

| Accuracy | Prone to human error in picking and placement | High accuracy with automated inventory tracking |

| Labor Requirements | High manual labor involvement | Minimal labor, primarily for maintenance and operation |

| Speed of Retrieval | Slower due to manual processes | Fast and consistent automated retrieval |

| Cost | Lower initial investment, higher ongoing labor costs | Higher upfront cost, lower operational expenses |

| Scalability | Limited by physical space and labor availability | Highly scalable with modular system expansion |

| Inventory Management | Manual tracking, less real-time visibility | Integrated software for real-time inventory control |

| Suitability | Best for large, uniform bulk items | Ideal for varied SKU storage and fast throughput |

Introduction to Modern Warehousing Solutions

Bulk storage maximizes space by stacking large quantities of uniform goods, ideal for high-volume, low-variety inventory management. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency with robotic mechanisms for precise handling, reducing labor costs and errors. Modern warehousing integrates these solutions to balance storage capacity with operational speed, optimizing overall supply chain performance.

Defining Bulk Storage: Concepts and Applications

Bulk storage involves storing large quantities of homogeneous goods in open spaces without individual packaging, using methods like pallets, bins, or large containers. It is typically applied in industries such as agriculture, chemicals, and raw materials handling, where high volume and easy access to products are essential. This method prioritizes space utilization and cost-efficiency but lacks the precision and speed offered by automated storage and retrieval systems (AS/RS).

Understanding Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) utilize computer-controlled systems and robotics to efficiently store and retrieve inventory in warehouses, significantly improving space utilization and operational speed compared to traditional bulk storage. AS/RS enhances inventory accuracy and reduces labor costs by automating repetitive tasks, enabling just-in-time inventory management and minimizing human error. Advanced AS/RS configurations, such as unit-load, mini-load, and carousel systems, cater to various load sizes and throughput requirements, optimizing warehouse productivity and scalability.

Key Differences Between Bulk Storage and AS/RS

Bulk storage involves large volumes of goods stored on pallets or in bins, optimized for maximum space utilization but often requires manual labor for retrieval. Automated Storage and Retrieval Systems (AS/RS) use robotics and computerized controls to automate the placement and retrieval of inventory, enhancing accuracy and operational speed. Key differences include AS/RS offering higher space efficiency, reduced labor costs, and real-time inventory tracking, whereas bulk storage remains more cost-effective for low turnover products and simpler inventory management.

Space Utilization: Bulk Storage vs AS/RS

Bulk storage maximizes floor space by stacking items on pallets or shelves but often requires wide aisles for forklift access, leading to lower space utilization efficiency. Automated Storage and Retrieval Systems (AS/RS) optimize vertical and horizontal space through compact, dense storage with narrow aisles enabled by automated machinery, achieving up to 70% higher storage density compared to traditional bulk storage. AS/RS also improves inventory accuracy and retrieval speed, further enhancing warehouse space optimization.

Efficiency and Workflow Optimization

Bulk storage maximizes space utilization by stacking large quantities of homogeneous goods, reducing handling times but often requiring manual labor that can slow workflow. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency through computerized inventory control and rapid, accurate picking, minimizing human error and accelerating throughput. Integrating AS/RS optimizes workflow by streamlining order fulfillment processes and enabling real-time inventory management, which elevates productivity beyond traditional bulk storage methods.

Cost Implications and ROI Analysis

Bulk storage systems require lower initial capital expenditures but often incur higher long-term labor and inventory carrying costs due to manual handling and space inefficiencies. Automated Storage and Retrieval Systems (AS/RS) involve significant upfront investment in technology and infrastructure but deliver enhanced operational efficiency, reduced labor expenses, and improved space utilization, driving faster ROI through increased throughput and accuracy. Detailed ROI analysis should factor in total cost of ownership, including maintenance, scalability, and productivity gains, to determine the optimal warehousing solution.

Scalability and Flexibility in Storage Solutions

Bulk storage offers high scalability by accommodating large volumes of uniform goods in open warehouse spaces, making it cost-effective for expanding inventory. Automated Storage and Retrieval Systems (AS/RS) provide enhanced flexibility through precise, programmable handling of diverse product types, enabling efficient space utilization and rapid adaptability to changing demand. Integrating AS/RS can optimize storage density and throughput, supporting scalable operations with dynamic inventory management.

Safety and Inventory Management Considerations

Bulk storage in warehousing offers straightforward inventory accessibility but poses higher risks of worker injury and product damage due to manual handling and stacking limitations. Automated Storage and Retrieval Systems (ASRS) enhance safety by minimizing human intervention, reducing accidents, and improving precision in inventory tracking through real-time data integration. Effective inventory management is significantly optimized in ASRS environments, ensuring accurate stock levels, faster retrieval times, and better space utilization compared to traditional bulk storage methods.

Choosing the Right Storage System for Your Warehouse

Bulk storage maximizes capacity by stacking large quantities of similar items, making it ideal for warehouses with high volume and low SKU variety. Automated Storage and Retrieval Systems (AS/RS) enhance efficiency and accuracy by integrating robotics and software, suitable for facilities requiring fast order fulfillment and complex inventory management. Choosing the right storage system depends on factors such as inventory turnover rate, space utilization, labor costs, and the specific operational goals of the warehouse.

Related Important Terms

Micro-Fulfillment Centers

Bulk storage maximizes space by stacking large quantities of homogeneous goods, ideal for slower-moving inventory in micro-fulfillment centers, whereas Automated Storage and Retrieval Systems (AS/RS) enhance efficiency through robotic automation, enabling rapid, precise handling of diverse, high-turnover items critical for fast-paced urban fulfillment operations. Micro-fulfillment centers benefit from AS/RS by significantly reducing order cycle times and labor costs while optimizing limited space, contrasting with bulk storage's simpler, less flexible approach.

Robotic Shuttle Systems

Robotic Shuttle Systems in automated storage and retrieval offer higher efficiency and space utilization compared to traditional bulk storage by enabling rapid, precise movement of goods in dense, multi-level racks. These systems reduce labor costs and improve inventory accuracy through real-time tracking and seamless integration with warehouse management software.

High-Bay Automated Storage

High-bay automated storage systems maximize vertical space utilization, increasing storage density by up to 70% compared to traditional bulk storage methods. These systems enable faster inventory retrieval through integrated robotics and software, reducing labor costs and minimizing errors in large-scale warehousing operations.

Pallet Shuttle Racking

Bulk storage maximizes space by stacking pallets directly but limits retrieval speed and flexibility, causing inefficiencies in high-throughput warehouses. Pallet Shuttle Racking, an advanced form of Automated Storage and Retrieval System (AS/RS), enhances storage density and operational efficiency by using motorized shuttles to transport pallets within racking lanes, significantly reducing handling time and increasing pick accuracy.

Dynamic Slotting Algorithms

Dynamic slotting algorithms in bulk storage optimize space utilization by continuously analyzing inventory turnover rates and adjusting slot assignments accordingly. In automated storage and retrieval systems (AS/RS), these algorithms enhance efficiency by enabling real-time inventory location updates, reducing retrieval time and improving throughput.

Goods-to-Person (G2P) Picking

Bulk storage maximizes space utilization by stacking large quantities of uniform goods, but often requires manual picking, leading to slower retrieval times and increased labor costs. Automated Storage and Retrieval Systems (AS/RS) utilizing Goods-to-Person (G2P) technology streamline the picking process by delivering items directly to operators, significantly enhancing efficiency, accuracy, and throughput in high-volume warehouse operations.

Vertical Lift Modules (VLM)

Bulk storage maximizes floor space by stacking large quantities of inventory but often requires more manual labor and longer retrieval times. Automated Storage and Retrieval Systems (ASRS), specifically Vertical Lift Modules (VLM), enhance space utilization by up to 85%, improve picking accuracy, and reduce labor costs through automated vertical lifts that deliver items directly to the operator.

Dense Buffer Storage

Dense buffer storage in bulk warehousing maximizes space utilization by stacking large quantities of uniform goods in a compact area, whereas automated storage and retrieval systems (AS/RS) enhance operational efficiency through robotic handling and precise inventory management in high-density configurations. Integrating dense buffer storage with AS/RS technology reduces labor costs and retrieval times, improving overall warehouse throughput and accuracy.

Automated Storage Density Index

The Automated Storage Density Index (ASDI) measures the efficiency of space utilization in Automated Storage and Retrieval Systems (AS/RS), indicating higher storage density compared to traditional bulk storage by maximizing vertical space and minimizing aisle width. AS/RS optimizes inventory management and throughput, delivering superior storage capacity within limited warehouse footprints while reducing labor costs and retrieval times.

Hybrid Bulk-Automation Integration

Hybrid Bulk-Automation Integration in warehousing combines the high-density capacity of bulk storage with the precision and speed of Automated Storage and Retrieval Systems (AS/RS), optimizing space utilization and operational efficiency. This integration enables real-time inventory management and faster order fulfillment by seamlessly blending manual and automated processes, reducing labor costs and minimizing errors.

Bulk Storage vs Automated Storage and Retrieval System Infographic

industrydif.com

industrydif.com