Inventory management optimizes stock levels to ensure accurate tracking and timely replenishment, reducing stockouts and overstock situations. Dark store fulfillment leverages dedicated warehouse spaces to process online orders quickly, prioritizing speed and efficiency for e-commerce delivery. Efficient integration of inventory management with dark store operations enhances order accuracy and customer satisfaction while minimizing fulfillment costs.

Table of Comparison

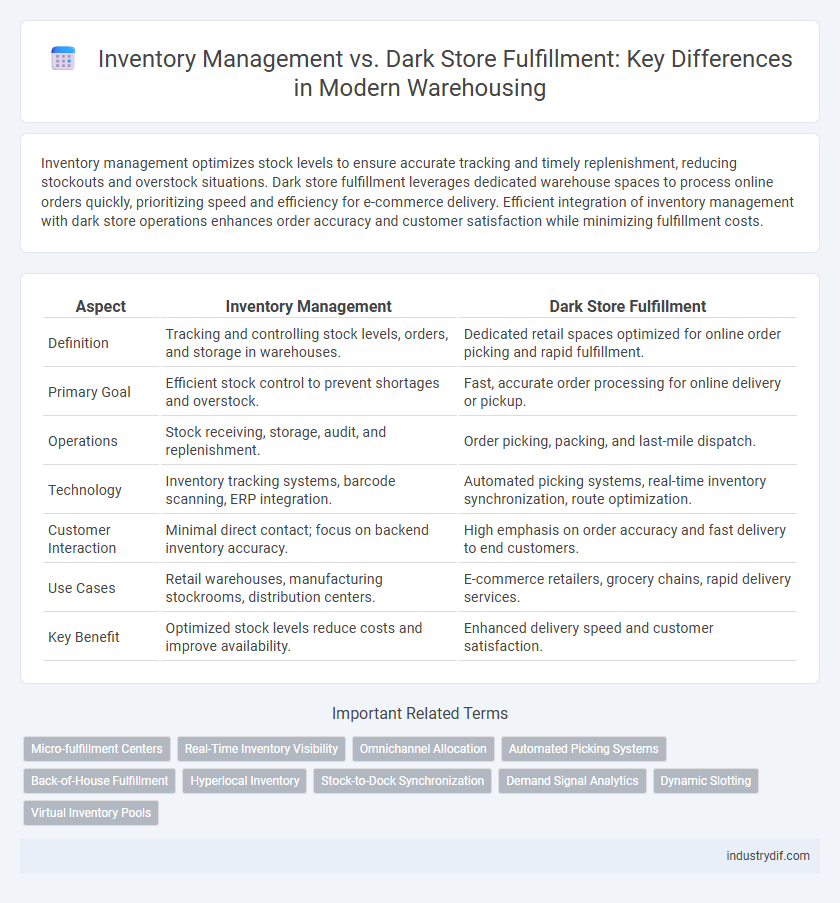

| Aspect | Inventory Management | Dark Store Fulfillment |

|---|---|---|

| Definition | Tracking and controlling stock levels, orders, and storage in warehouses. | Dedicated retail spaces optimized for online order picking and rapid fulfillment. |

| Primary Goal | Efficient stock control to prevent shortages and overstock. | Fast, accurate order processing for online delivery or pickup. |

| Operations | Stock receiving, storage, audit, and replenishment. | Order picking, packing, and last-mile dispatch. |

| Technology | Inventory tracking systems, barcode scanning, ERP integration. | Automated picking systems, real-time inventory synchronization, route optimization. |

| Customer Interaction | Minimal direct contact; focus on backend inventory accuracy. | High emphasis on order accuracy and fast delivery to end customers. |

| Use Cases | Retail warehouses, manufacturing stockrooms, distribution centers. | E-commerce retailers, grocery chains, rapid delivery services. |

| Key Benefit | Optimized stock levels reduce costs and improve availability. | Enhanced delivery speed and customer satisfaction. |

Introduction to Inventory Management and Dark Store Fulfillment

Inventory management involves systematically tracking and controlling stock levels to optimize storage, reduce costs, and ensure product availability. Dark store fulfillment refers to dedicated warehouses designed to process online orders rapidly without physical retail access, enhancing e-commerce logistics efficiency. Integrating advanced inventory management techniques within dark stores improves order accuracy, reduces fulfillment time, and supports scalable operations in high-demand environments.

Key Differences Between Inventory Management and Dark Store Fulfillment

Inventory management involves tracking stock levels, orders, sales, and deliveries to optimize warehouse operations, whereas dark store fulfillment focuses on converting traditional retail spaces into dedicated warehouses for fast e-commerce order processing. Inventory management emphasizes accuracy in stock data and replenishment cycles, while dark store fulfillment prioritizes rapid picking, packing, and last-mile delivery efficiency. The key difference lies in inventory management's broader scope of supply chain coordination versus dark store fulfillment's specialization in immediate customer order turnaround.

Advantages of Traditional Inventory Management

Traditional inventory management provides accurate stock tracking and real-time visibility across warehouses, enabling efficient order fulfillment and reducing stockouts. It supports diverse inventory types and bulk storage, accommodating large product assortments with systematic organization. This method optimizes supply chain coordination, lowers holding costs, and ensures consistent product availability for both online and offline sales channels.

Benefits of Dark Store Fulfillment in E-commerce

Dark store fulfillment enhances e-commerce efficiency by enabling faster order processing and reducing delivery times through localized inventory allocation. It optimizes inventory management by minimizing stockouts and overstock situations, leveraging real-time data analytics for precise demand forecasting. This model also improves customer satisfaction by offering more accurate order fulfillment and seamless last-mile delivery options.

Technology Integration in Modern Warehousing

Inventory management in modern warehousing leverages advanced technologies such as RFID, IoT sensors, and AI-driven analytics to optimize stock levels and improve accuracy. Dark store fulfillment integrates these technologies with real-time data processing and automated picking systems to enhance order speed and reduce errors. Seamless technology integration ensures agility and efficiency across both inventory management and dark store operations, driving superior supply chain performance.

Inventory Accuracy and Real-Time Tracking

Inventory management systems enhance accuracy by continuously updating stock levels through automated data capture and real-time synchronization across warehouses. Dark store fulfillment relies heavily on precise inventory accuracy to ensure rapid order processing and minimize out-of-stock situations, using advanced real-time tracking technologies such as RFID and IoT sensors. Integrating these technologies optimizes both stock visibility and fulfillment speed, reducing errors and improving overall operational efficiency.

Cost Implications and Operational Efficiency

Inventory management optimizes stock levels and reduces holding costs by aligning supply with demand, enhancing operational efficiency through accurate tracking and replenishment systems. Dark store fulfillment minimizes last-mile delivery expenses by operating as dedicated local warehouses, speeding order processing and reducing transportation costs. Comparing both, inventory management controls capital tied up in goods, while dark stores cut delivery costs, making a hybrid approach valuable for balancing overall warehousing expenses and efficiency.

Challenges in Implementing Dark Store Fulfillment

Implementing dark store fulfillment presents significant challenges including its high initial investment costs, the need for advanced inventory management systems to ensure real-time stock accuracy, and the complexity of optimizing warehouse layouts for rapid order picking and packing. Dark stores require seamless integration between e-commerce platforms and warehouse management software to prevent stockouts and delays, demanding robust IT infrastructure and skilled personnel. Operational scalability and maintaining service levels during peak demand periods further complicate the transition from traditional inventory management to dark store models.

Future Trends in Warehousing and Fulfillment Strategies

Inventory management is evolving with AI-driven demand forecasting and real-time stock visibility, enabling more precise replenishment and reduced carrying costs. Dark store fulfillment integrates micro-fulfillment centers closer to urban areas, accelerating delivery times and supporting omnichannel strategies. Future trends emphasize automation, data analytics, and sustainable practices to enhance operational efficiency and meet rising consumer expectations in warehousing and fulfillment.

Choosing the Right Approach for Your Business

Inventory management optimizes stock levels through real-time tracking and demand forecasting, ensuring efficient replenishment and minimizing holding costs. Dark store fulfillment prioritizes rapid order processing and localized delivery by operating dedicated warehouses designed exclusively for e-commerce. Selecting the right approach depends on your business model, order volume, and customer expectations for delivery speed and accuracy.

Related Important Terms

Micro-fulfillment Centers

Micro-fulfillment centers optimize inventory management by utilizing automated storage and retrieval systems to enhance order accuracy and reduce fulfillment time, directly supporting dark store fulfillment models. These centers enable efficient handling of high SKU density in limited spaces, driving faster last-mile delivery and improving overall supply chain responsiveness in urban environments.

Real-Time Inventory Visibility

Real-time inventory visibility enhances both inventory management and dark store fulfillment by enabling accurate stock monitoring and immediate updates across all sales channels. This synchronization reduces stockouts and overstocks, ensuring efficient order processing and improved customer satisfaction in dynamic warehousing environments.

Omnichannel Allocation

Omnichannel allocation in inventory management ensures seamless stock distribution across physical warehouses and dark stores, optimizing product availability and delivery speed. Dark store fulfillment leverages localized inventory pools to enhance last-mile efficiency, reducing lead times and meeting diverse channel demands effectively.

Automated Picking Systems

Automated picking systems enhance inventory management by increasing accuracy and reducing labor costs through real-time stock tracking and efficient order processing. In dark store fulfillment, these systems optimize the rapid selection and dispatch of items, enabling faster delivery times and higher order throughput in a controlled warehouse environment.

Back-of-House Fulfillment

Back-of-house fulfillment in inventory management optimizes stock accuracy and real-time tracking to reduce errors and enhance order processing speed. Dark store fulfillment leverages dedicated retail spaces for efficient picking and packing, minimizing customer wait times and streamlining last-mile delivery in high-demand urban areas.

Hyperlocal Inventory

Hyperlocal inventory in warehousing enhances efficiency by positioning stock closer to the end customer, reducing delivery times and enabling real-time inventory management. Inventory management leverages data analytics to optimize stock levels across multiple locations, while dark store fulfillment focuses on converting retail spaces into local distribution centers specifically designed for rapid order processing within hyperlocal areas.

Stock-to-Dock Synchronization

Inventory management in warehousing optimizes stock levels through accurate demand forecasting and real-time tracking, ensuring efficient stock-to-dock synchronization. Dark store fulfillment relies on precise inventory synchronization between storage and dispatch zones to accelerate order processing and minimize stockouts.

Demand Signal Analytics

Demand Signal Analytics enhances inventory management by providing real-time insights into customer purchasing patterns, enabling precise stock replenishment and reducing overstock risks. In dark store fulfillment, these analytics optimize product assortment and order allocation to ensure rapid delivery and increased operational efficiency.

Dynamic Slotting

Dynamic slotting enhances inventory management by continuously analyzing order patterns to optimize product placement, reducing picking time and errors. In dark store fulfillment, dynamic slotting maximizes storage efficiency and accelerates order processing by adapting layouts based on real-time data and demand fluctuations.

Virtual Inventory Pools

Virtual inventory pools enable seamless integration of inventory across multiple locations, optimizing stock visibility and allocation in both inventory management and dark store fulfillment. This approach reduces fulfillment costs and delivery times by dynamically assigning orders to the nearest available stock within the virtual network.

Inventory Management vs Dark Store Fulfillment Infographic

industrydif.com

industrydif.com