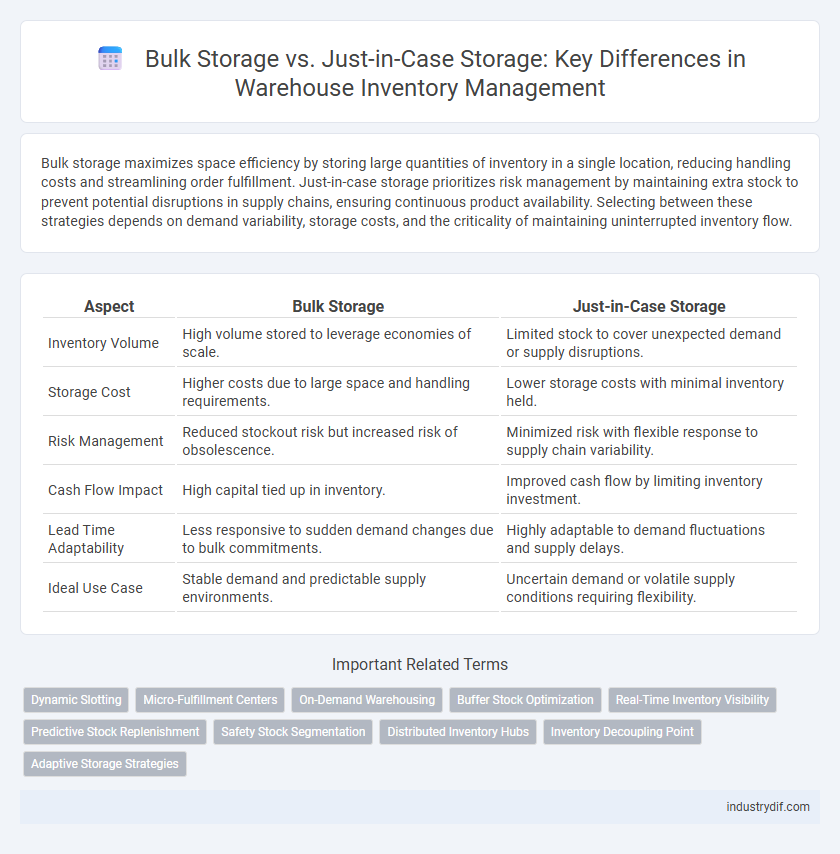

Bulk storage maximizes space efficiency by storing large quantities of inventory in a single location, reducing handling costs and streamlining order fulfillment. Just-in-case storage prioritizes risk management by maintaining extra stock to prevent potential disruptions in supply chains, ensuring continuous product availability. Selecting between these strategies depends on demand variability, storage costs, and the criticality of maintaining uninterrupted inventory flow.

Table of Comparison

| Aspect | Bulk Storage | Just-in-Case Storage |

|---|---|---|

| Inventory Volume | High volume stored to leverage economies of scale. | Limited stock to cover unexpected demand or supply disruptions. |

| Storage Cost | Higher costs due to large space and handling requirements. | Lower storage costs with minimal inventory held. |

| Risk Management | Reduced stockout risk but increased risk of obsolescence. | Minimized risk with flexible response to supply chain variability. |

| Cash Flow Impact | High capital tied up in inventory. | Improved cash flow by limiting inventory investment. |

| Lead Time Adaptability | Less responsive to sudden demand changes due to bulk commitments. | Highly adaptable to demand fluctuations and supply delays. |

| Ideal Use Case | Stable demand and predictable supply environments. | Uncertain demand or volatile supply conditions requiring flexibility. |

Introduction to Bulk Storage and Just-in-Case Storage

Bulk storage involves holding large quantities of goods in a warehouse to capitalize on economies of scale, reduce ordering frequency, and ensure availability during demand spikes. Just-in-case storage emphasizes maintaining strategic inventory reserves as a risk management strategy to buffer against supply chain disruptions, unexpected demand surges, or delays. Both methods require optimized space utilization and inventory tracking to balance cost efficiency with operational reliability.

Key Principles of Bulk Storage

Bulk storage in warehousing emphasizes maximizing space utilization through high-density stacking and efficient inventory organization to handle large quantities of homogeneous products. It relies on principles such as minimizing handling by storing items in their original packaging and optimizing layout for easy access and flow. This method reduces operational costs and supports economies of scale compared to just-in-case storage, which maintains safety stock for unpredictable demand.

Core Concepts of Just-in-Case Storage

Just-in-case storage focuses on maintaining a strategic inventory buffer to mitigate supply chain disruptions and unexpected demand spikes. This approach prioritizes stock availability by holding excess inventory beyond immediate needs, reducing the risk of stockouts and ensuring continuity in production or sales. Key components include safety stock levels, risk assessment, and supplier reliability to balance holding costs against service level objectives.

Advantages of Bulk Storage Systems

Bulk storage systems offer significant advantages including higher space utilization by storing large volumes of goods in a compact area, which reduces overall storage costs. These systems facilitate faster inventory turnover and streamlined logistics by consolidating items, improving warehouse efficiency and reducing handling times. Bulk storage also enhances product protection through controlled environments, minimizing damage and spoilage for extended inventory lifespan.

Benefits of Just-in-Case Inventory Strategies

Just-in-case inventory strategies offer significant advantages in warehousing by ensuring product availability during unexpected demand surges or supply chain disruptions, minimizing stockouts and lost sales. This approach enhances customer satisfaction and reliability by maintaining safety stock levels that buffer against uncertainties. Companies employing just-in-case storage benefit from improved risk management and operational continuity despite fluctuating market conditions.

Operational Differences Between Bulk and Just-in-Case Storage

Bulk storage involves holding large quantities of inventory to meet anticipated demand, optimizing space utilization and reducing order frequency. Just-in-case storage maintains minimal stock levels as a precaution against supply chain disruptions, emphasizing agility and quick replenishment. Operationally, bulk storage requires extensive warehouse space and inventory management systems, while just-in-case storage prioritizes rapid turnover and responsiveness to market fluctuations.

Cost Implications: Bulk vs Just-in-Case Storage

Bulk storage typically incurs higher upfront costs due to the need for extensive space, specialized shelving, and inventory management systems, but it can reduce per-unit storage expenses through economies of scale. Just-in-case storage, by maintaining smaller, more flexible stock levels, minimizes carrying costs and reduces risks associated with obsolescence and excess inventory. Choosing between bulk and just-in-case storage strategies requires balancing space utilization and capital costs against demand uncertainty and service level objectives.

Space Utilization and Efficiency Comparison

Bulk storage maximizes space utilization by consolidating large quantities of inventory in fewer, larger storage areas, reducing handling and optimizing vertical storage capacity. Just-in-case storage prioritizes inventory risk mitigation, often resulting in increased safety stock levels that require more space and decrease overall storage efficiency. Comparing the two, bulk storage is more efficient for predictable demand patterns, while just-in-case storage demands greater space allocation to accommodate higher inventory buffers.

Best Industries for Bulk and Just-in-Case Storage

Bulk storage is ideal for industries like agriculture, mining, and manufacturing where large quantities of raw materials or products require efficient, cost-effective warehousing. Just-in-case storage suits industries such as pharmaceuticals, electronics, and automotive, where inventory buffering is critical to mitigate supply chain disruptions and ensure continuous production. Choosing the right storage method hinges on balancing inventory costs with supply chain reliability specific to each industry's demand patterns.

Choosing the Right Warehousing Approach for Your Business

Bulk storage maximizes space efficiency by storing large quantities of uniform products, ideal for businesses with stable demand and predictable inventory turnover. Just-in-case storage emphasizes maintaining safety stock to prevent stockouts during supply chain disruptions, suitable for businesses facing demand volatility or supplier uncertainties. Selecting the optimal warehousing approach depends on analyzing demand patterns, lead times, and risk tolerance to balance inventory costs and service levels.

Related Important Terms

Dynamic Slotting

Dynamic slotting enhances bulk storage efficiency by continuously reallocating inventory locations based on real-time demand patterns, minimizing space waste and retrieval times. In just-in-case storage, dynamic slotting adapts to fluctuating safety stock levels, ensuring critical items remain easily accessible without overcommitting warehouse capacity.

Micro-Fulfillment Centers

Micro-fulfillment centers leverage bulk storage to maximize space efficiency and reduce replenishment frequency, contrasting with just-in-case storage that prioritizes safety stock levels for demand variability. Optimizing inventory management in micro-fulfillment centers involves balancing bulk storage benefits with agile replenishment to meet rapid fulfillment requirements.

On-Demand Warehousing

On-demand warehousing leverages bulk storage capacity by dynamically allocating space based on real-time demand, optimizing inventory management compared to traditional just-in-case storage, which relies on excess stock and fixed warehouse space. This flexible approach reduces carrying costs and improves supply chain responsiveness by aligning storage resources with fluctuating market needs.

Buffer Stock Optimization

Bulk storage enables warehouses to maintain large quantities of buffer stock, reducing the risk of stockouts during demand fluctuations but increasing holding costs and space requirements. Just-in-case storage optimizes buffer stock by balancing sufficient inventory levels to meet unexpected demand while minimizing excess stock, improving cash flow and warehouse efficiency.

Real-Time Inventory Visibility

Bulk storage relies on large quantities of goods stored for extended periods, often leading to challenges in maintaining real-time inventory visibility due to infrequent updates. Just-in-case storage, by contrast, emphasizes smaller, strategically placed stock levels with continuous tracking systems, enabling accurate and up-to-date inventory data for rapid decision-making.

Predictive Stock Replenishment

Bulk storage enables efficient handling of large inventory volumes, optimizing space and reducing costs, while just-in-case storage prioritizes safety stock to mitigate supply chain disruptions. Predictive stock replenishment leverages real-time data analytics and demand forecasting to balance inventory levels, ensuring timely restocking in both bulk and just-in-case systems to prevent stockouts and minimize excess holding costs.

Safety Stock Segmentation

Safety stock segmentation in warehousing differentiates Bulk Storage, which holds large quantities of items to mitigate supply chain disruptions, from Just-in-Case Storage that maintains minimal reserve inventory tailored to specific demand scenarios. Effective segmentation balances inventory costs and service levels by aligning safety stock levels with demand variability, lead times, and product criticality to optimize storage space and reduce stockouts.

Distributed Inventory Hubs

Distributed inventory hubs enhance efficiency by combining bulk storage capacity with just-in-case storage strategies, allowing companies to maintain larger stock levels closer to demand centers and reduce lead times. This approach optimizes inventory availability and mitigates supply chain disruptions through strategic placement of regional warehouses.

Inventory Decoupling Point

Bulk storage enables efficient inventory decoupling by holding large quantities of goods upstream in the supply chain, reducing variability impact and ensuring continuous production flow. Just-in-case storage, positioned closer to customer demand, provides a buffer against unforeseen disruptions, minimizing stockouts but increasing holding costs and inventory risk.

Adaptive Storage Strategies

Adaptive storage strategies balance bulk storage and just-in-case storage by optimizing inventory levels based on demand variability and supply chain disruptions, enhancing warehouse efficiency and reducing holding costs. Implementing data-driven forecasting and real-time analytics enables warehouses to dynamically switch between storing large quantities and maintaining minimal safety stocks, ensuring responsiveness and risk mitigation.

Bulk Storage vs Just-in-Case Storage Infographic

industrydif.com

industrydif.com