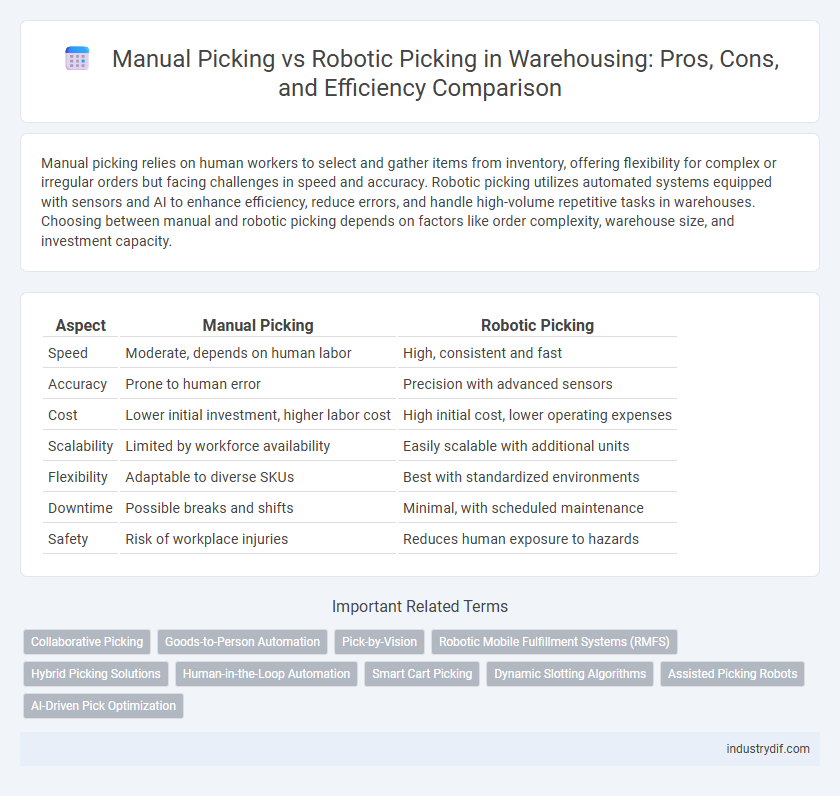

Manual picking relies on human workers to select and gather items from inventory, offering flexibility for complex or irregular orders but facing challenges in speed and accuracy. Robotic picking utilizes automated systems equipped with sensors and AI to enhance efficiency, reduce errors, and handle high-volume repetitive tasks in warehouses. Choosing between manual and robotic picking depends on factors like order complexity, warehouse size, and investment capacity.

Table of Comparison

| Aspect | Manual Picking | Robotic Picking |

|---|---|---|

| Speed | Moderate, depends on human labor | High, consistent and fast |

| Accuracy | Prone to human error | Precision with advanced sensors |

| Cost | Lower initial investment, higher labor cost | High initial cost, lower operating expenses |

| Scalability | Limited by workforce availability | Easily scalable with additional units |

| Flexibility | Adaptable to diverse SKUs | Best with standardized environments |

| Downtime | Possible breaks and shifts | Minimal, with scheduled maintenance |

| Safety | Risk of workplace injuries | Reduces human exposure to hazards |

Introduction to Manual and Robotic Picking

Manual picking in warehousing involves human workers selecting and retrieving items from storage locations, offering flexibility and adaptability for complex orders but with limitations in speed and accuracy. Robotic picking utilizes automated systems and robots equipped with sensors and AI to identify, grasp, and move products, significantly improving efficiency and reducing errors in high-volume operations. Integrating robotic picking enhances throughput and consistency, while manual picking remains essential for handling diverse and irregularly shaped items.

Core Differences Between Manual and Robotic Picking

Manual picking relies on human workers to identify, locate, and retrieve items, offering flexibility in handling diverse and irregular products but often resulting in slower processing speeds. Robotic picking utilizes automated systems such as robotic arms and conveyor belts, enhancing speed, accuracy, and consistency while reducing human error and labor costs. The core differences stem from manual picking's adaptability and human decision-making versus robotic picking's efficiency and scalability in high-volume warehouse operations.

Efficiency and Speed: Human vs. Robots

Robotic picking systems in warehousing significantly enhance efficiency and speed by rapidly identifying and retrieving items with precise automation, reducing errors and downtime commonly experienced in manual picking. Human pickers, while adaptable to complex or irregular items, typically operate at slower speeds and require breaks, limiting throughput compared to continuous robotic operations. Integrating advanced robotic picking technologies can achieve up to a 50-70% increase in order fulfillment speed, optimizing warehouse productivity and reducing labor costs.

Accuracy and Error Rates in Picking Methods

Manual picking in warehousing often results in higher error rates due to human fatigue and miscommunication, with accuracy typically ranging between 85% to 98%. Robotic picking systems leverage advanced sensors and machine learning algorithms to consistently achieve accuracy levels above 99%, minimizing errors in order fulfillment. Implementing robotic solutions reduces inaccuracies and improves overall inventory reliability, significantly lowering operational costs related to returns and restocking.

Labor Costs and Operational Expenses

Manual picking in warehousing leads to higher labor costs due to the need for extensive human workforce and associated expenses such as wages, benefits, and training. Robotic picking systems reduce operational expenses by minimizing human errors and increasing pick speeds, which enhances overall efficiency and lowers long-term maintenance costs. Investing in automation technology leads to significant savings on labor while optimizing inventory management and throughput in high-volume warehouses.

Scalability and Flexibility of Picking Systems

Manual picking offers high flexibility by allowing workers to adapt to varying order types and product assortments, making it suitable for businesses with diverse inventory or seasonal demand fluctuations. Robotic picking systems excel in scalability, enabling warehouses to rapidly increase throughput by adding or upgrading automation units, which reduces labor costs and enhances consistency in high-volume operations. Combining both approaches can optimize warehouse performance by balancing the adaptability of manual processes with the efficiency and scalability of robotic solutions.

Technology Integration and Warehouse Automation

Robotic picking integrates advanced AI and machine learning technologies to significantly enhance warehouse automation, improving accuracy and operational speed compared to manual picking. Automated systems utilize sensors, vision technologies, and robotics to reduce human error and increase throughput in high-volume environments. Manual picking relies heavily on human labor, which limits scalability and efficiency despite its flexibility in handling diverse products.

Safety and Ergonomics in Picking Operations

Manual picking in warehousing often leads to repetitive strain injuries due to prolonged bending and lifting, posing significant ergonomic risks for workers. Robotic picking systems enhance safety by minimizing human exposure to heavy loads and hazardous environments, reducing workplace accidents. Implementing robotic solutions improves overall ergonomic conditions, increasing worker well-being and operational efficiency.

Environmental Impact and Energy Consumption

Manual picking in warehousing typically results in higher energy consumption due to human labor needs and associated infrastructure such as lighting and climate control. Robotic picking systems, powered by efficient motors and automation technologies, reduce energy usage by optimizing pick paths and minimizing idle times, thus lowering overall carbon emissions. The shift to robotics also decreases reliance on fossil fuels by integrating renewable energy sources and smart grid management within automated warehouses.

Future Trends in Warehouse Picking Solutions

Future trends in warehouse picking solutions emphasize increasing automation through advanced robotic picking systems equipped with AI and machine learning for enhanced accuracy and efficiency. Manual picking remains relevant in handling complex or delicate items, but integration with augmented reality and wearable technologies is improving picker productivity. Hybrid approaches combining human flexibility with robotic precision are expected to dominate, optimizing throughput while reducing errors and operational costs.

Related Important Terms

Collaborative Picking

Collaborative picking integrates manual and robotic systems to optimize warehouse efficiency by combining human flexibility with robotic precision, reducing errors and increasing throughput. This synergy enhances order accuracy and operational speed while minimizing worker fatigue and improving overall productivity.

Goods-to-Person Automation

Goods-to-person automation significantly enhances efficiency by reducing travel time and error rates compared to manual picking, which relies heavily on human labor and is prone to fatigue and mistakes. Robotic picking systems integrate advanced sensors and AI technology to streamline order fulfillment, increasing throughput and accuracy in warehouses.

Pick-by-Vision

Pick-by-Vision technology in manual picking enhances accuracy and speed by providing real-time visual guidance via smart glasses, reducing errors and training time in warehousing operations. Compared to robotic picking systems, Pick-by-Vision maintains human flexibility and decision-making while leveraging digital augmentation to optimize order fulfillment efficiency.

Robotic Mobile Fulfillment Systems (RMFS)

Robotic Mobile Fulfillment Systems (RMFS) significantly enhance warehouse efficiency by automating the picking process, reducing human error, and increasing throughput compared to manual picking. These systems leverage autonomous mobile robots to transport inventory pods directly to workers, optimizing space utilization and minimizing travel time within the warehouse.

Hybrid Picking Solutions

Hybrid picking solutions integrate manual picking efficiency with robotic precision, enhancing order accuracy and throughput in warehouse operations. This synergy optimizes labor costs while adapting to varying SKU densities and complex order profiles, driving scalable productivity improvements.

Human-in-the-Loop Automation

Human-in-the-loop automation in warehousing combines manual picking with robotic systems to enhance accuracy and efficiency by enabling real-time human oversight during automated processes. This hybrid approach reduces errors and increases throughput by leveraging human judgment for exception handling while robots manage repetitive tasks.

Smart Cart Picking

Smart cart picking enhances warehouse efficiency by combining manual selection with automated guidance, reducing errors and increasing picking speed compared to traditional manual methods. Integration of sensors and real-time data in smart carts allows for dynamic route optimization and inventory accuracy, outperforming fully robotic picking systems in flexibility and cost-effectiveness.

Dynamic Slotting Algorithms

Dynamic slotting algorithms significantly enhance manual picking efficiency by optimizing product locations based on demand patterns, reducing picker travel time and errors. In robotic picking systems, these algorithms adapt to real-time inventory changes, enabling robots to select items with increased accuracy and throughput, thereby improving overall warehouse productivity.

Assisted Picking Robots

Assisted picking robots enhance warehouse efficiency by combining human decision-making with robotic precision, reducing errors and increasing throughput by up to 30%. These semi-autonomous systems optimize order accuracy and speed in complex environments where full automation is impractical.

AI-Driven Pick Optimization

AI-driven pick optimization in warehousing significantly enhances both manual and robotic picking by leveraging machine learning algorithms to analyze real-time data, reducing errors and increasing throughput. Robotic picking systems equipped with AI optimize route planning and item recognition, while AI-assisted manual picking improves worker efficiency through smart guidance and adaptive workload distribution.

Manual Picking vs Robotic Picking Infographic

industrydif.com

industrydif.com