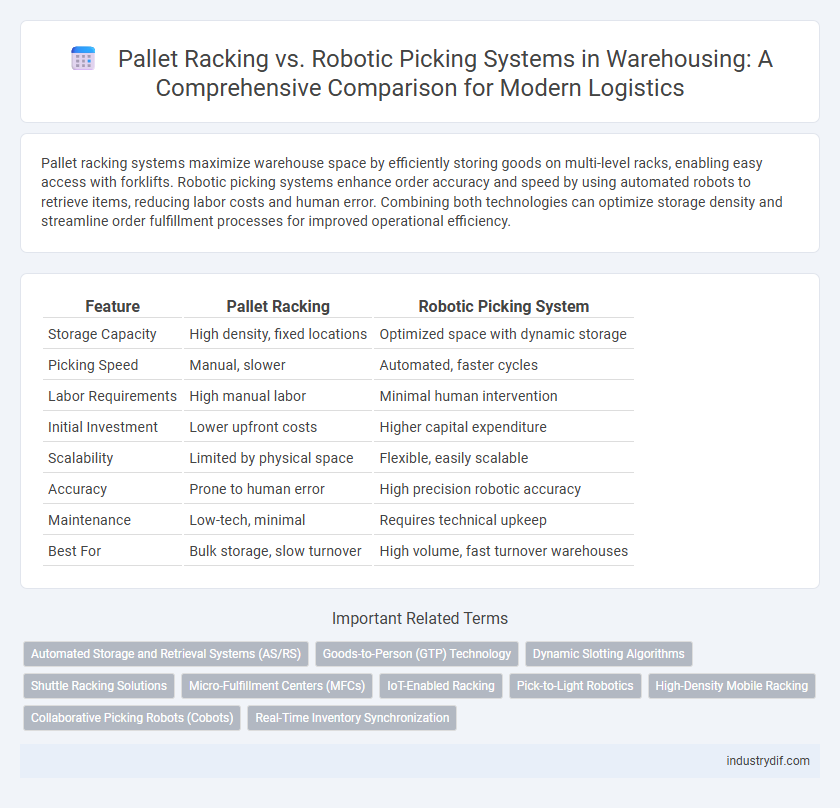

Pallet racking systems maximize warehouse space by efficiently storing goods on multi-level racks, enabling easy access with forklifts. Robotic picking systems enhance order accuracy and speed by using automated robots to retrieve items, reducing labor costs and human error. Combining both technologies can optimize storage density and streamline order fulfillment processes for improved operational efficiency.

Table of Comparison

| Feature | Pallet Racking | Robotic Picking System |

|---|---|---|

| Storage Capacity | High density, fixed locations | Optimized space with dynamic storage |

| Picking Speed | Manual, slower | Automated, faster cycles |

| Labor Requirements | High manual labor | Minimal human intervention |

| Initial Investment | Lower upfront costs | Higher capital expenditure |

| Scalability | Limited by physical space | Flexible, easily scalable |

| Accuracy | Prone to human error | High precision robotic accuracy |

| Maintenance | Low-tech, minimal | Requires technical upkeep |

| Best For | Bulk storage, slow turnover | High volume, fast turnover warehouses |

Introduction to Warehousing Storage Solutions

Pallet racking systems offer structured, high-density storage with easy accessibility for forklifts, optimizing space utilization and inventory organization in warehouses. Robotic picking systems use automation and AI-driven robots to enhance picking speed and accuracy, reducing labor costs and human error. Combining both technologies can improve overall warehouse efficiency by balancing storage capacity with advanced picking capabilities.

Overview of Pallet Racking Systems

Pallet racking systems are essential for optimizing warehouse storage by providing structured, vertical storage solutions that maximize floor space and improve inventory accessibility. These systems include selective, drive-in, push-back, and pallet flow racks, each designed to accommodate varying load types and handling methods. Their scalability and compatibility with forklifts make them a cost-effective choice for high-density storage in diverse warehousing environments.

Fundamentals of Robotic Picking Systems

Robotic picking systems utilize advanced automation technologies including sensors, machine vision, and artificial intelligence to identify, select, and retrieve items from warehouse pallets with high precision and speed. Unlike traditional pallet racking which relies on manual labor for item retrieval, robotic systems enhance operational efficiency, reduce human error, and optimize space utilization within fulfillment centers. The fundamental components involve robotic arms, conveyor integration, and real-time inventory tracking to streamline order picking processes and support scalable warehouse automation.

Space Utilization: Pallet Racking vs Robotic Picking

Pallet racking maximizes vertical storage space by efficiently stacking pallets in multi-level structures, making it ideal for high-density inventory environments. Robotic picking systems optimize floor space by using automated guided vehicles and compact shelving, reducing aisle widths and increasing storage density. While pallet racking excels in traditional bulk storage, robotic picking offers superior space utilization through dynamic, flexible layouts that adapt to warehouse workflows.

Labor Efficiency and Automation Impact

Pallet racking systems maximize storage density and improve manual order picking efficiency by organizing inventory for quicker access, reducing labor time per task. Robotic picking systems leverage automation to significantly boost labor efficiency, minimizing human errors and operational costs through continuous, precise item retrieval. The integration of automation with pallet racking enhances throughput, accelerates order fulfillment, and optimizes workforce allocation in modern warehouses.

Cost Analysis: Initial Investment and Long-Term ROI

Pallet racking systems require lower initial investment costs, typically ranging from $25 to $50 per pallet position, making them a cost-effective solution for basic storage needs. Robotic picking systems involve higher upfront expenses, often exceeding $500,000, due to the integration of automation technology and software, but they significantly reduce labor costs and improve accuracy over time. Long-term ROI favors robotic systems in high-volume warehouses, as improved picking speed and reduced errors lead to operational savings that offset the initial investment within 3 to 5 years.

Scalability and Flexibility in Warehousing

Pallet racking systems offer high scalability by allowing easy vertical and horizontal expansion to accommodate increasing inventory volumes, making them ideal for warehouses with steady growth. Robotic picking systems provide exceptional flexibility through programmable workflows and adaptable automation, enabling quick reconfiguration for varied product types and seasonal demand fluctuations. Combining these solutions enhances overall warehouse efficiency by balancing scalable storage capacity with dynamic order fulfillment capabilities.

Inventory Accuracy and Order Fulfillment Speed

Pallet racking systems provide reliable inventory storage with moderate accuracy dependent on manual scanning processes, whereas robotic picking systems enhance inventory accuracy through automated real-time data capture. Robotic picking significantly increases order fulfillment speed by reducing human error and enabling continuous operation, compared to the slower, labor-intensive retrieval associated with pallet racking. Integrating robotic picking with pallet racking can optimize both inventory accuracy and order fulfillment efficiency in modern warehouses.

Safety Considerations and Risk Management

Pallet racking systems require strict adherence to load limits and regular inspections to prevent structural failures, making safety training essential to minimize risks related to collapsing racks. Robotic picking systems reduce human exposure to hazardous environments and repetitive strain injuries, but they necessitate comprehensive risk assessments for automation hazards and emergency stop protocols. Integrating both systems demands a balanced safety management plan that addresses mechanical integrity, collision avoidance, and employee interaction with automated equipment.

Future Trends in Warehouse Storage Technologies

Pallet racking remains a foundational warehouse storage solution due to its cost-effectiveness and scalability, but emerging robotic picking systems are revolutionizing order fulfillment by enhancing speed and accuracy through AI-driven automation. Future trends emphasize the integration of autonomous mobile robots (AMRs) with advanced pallet racking to create hybrid storage systems that maximize space utilization and operational efficiency. Smart warehouses will increasingly adopt IoT sensors and machine learning algorithms to optimize inventory management and predictive maintenance in both pallet racking and robotic picking infrastructures.

Related Important Terms

Automated Storage and Retrieval Systems (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) in warehousing integrate pallet racking with robotic picking systems to optimize inventory management and increase throughput efficiency. Pallet racking provides high-density storage for bulk items, while robotic picking systems enhance order accuracy and speed by automating item retrieval and minimizing human error.

Goods-to-Person (GTP) Technology

Goods-to-Person (GTP) technology in warehousing significantly enhances efficiency by utilizing robotic picking systems that deliver items directly to workers, reducing travel time compared to traditional pallet racking where employees manually retrieve products. This automation increases order accuracy, optimizes space utilization, and accelerates throughput, making GTP systems ideal for high-volume, fast-paced distribution centers.

Dynamic Slotting Algorithms

Dynamic slotting algorithms optimize warehouse efficiency by continuously analyzing order patterns and inventory movement, enabling pallet racking systems to adapt storage locations for quicker access. Robotic picking systems leverage these algorithms to enhance automation precision, reducing pick times and increasing throughput by dynamically adjusting robot paths and storage assignments.

Shuttle Racking Solutions

Shuttle racking solutions optimize warehouse storage by combining high-density pallet racking with automated shuttle technology, enabling faster and more efficient order fulfillment compared to traditional pallet racking systems. Unlike robotic picking systems that handle individual items, shuttle racking streamlines pallet movement for bulk storage and retrieval, significantly reducing labor costs and increasing throughput in large-scale distribution centers.

Micro-Fulfillment Centers (MFCs)

Pallet racking in Micro-Fulfillment Centers (MFCs) maximizes vertical storage density, enabling efficient use of limited space while supporting high inventory volumes. Robotic picking systems enhance order accuracy and speed by automating item retrieval within compact aisles, reducing labor costs and increasing throughput in MFC operations.

IoT-Enabled Racking

IoT-enabled pallet racking systems integrate sensors and real-time data analytics to optimize space utilization and inventory tracking, significantly reducing picking errors and enhancing operational efficiency. In contrast, robotic picking systems rely on automated machines to retrieve items, but without IoT integration, they lack the dynamic adaptability and predictive maintenance capabilities that advanced IoT-enabled racking provides.

Pick-to-Light Robotics

Pick-to-Light robotics in warehouse automation significantly increases picking accuracy and speed compared to traditional pallet racking systems by using visual signals to guide operators directly to the inventory location, reducing errors and labor time. This technology integrates seamlessly with inventory management software, optimizing order fulfillment processes and enhancing overall operational efficiency.

High-Density Mobile Racking

High-Density Mobile Racking maximizes storage capacity by minimizing aisle space, offering greater density compared to traditional pallet racking systems, which typically require fixed aisles for manual access. Unlike robotic picking systems that emphasize automation and speed, high-density mobile racking optimizes space utilization and is ideal for warehouses prioritizing storage volume over rapid item retrieval.

Collaborative Picking Robots (Cobots)

Collaborative picking robots (cobots) enhance pallet racking systems by increasing picking accuracy and reducing labor costs through seamless human-robot interaction in warehouse environments. Unlike traditional robotic picking systems, cobots work safely alongside humans, optimizing space utilization and boosting operational efficiency in high-density storage facilities.

Real-Time Inventory Synchronization

Pallet racking systems provide organized, static storage solutions but often require manual updates for inventory tracking, leading to delays in real-time data accuracy. Robotic picking systems utilize automated sensors and integrated software to synchronize inventory instantly, ensuring up-to-date stock levels and minimizing errors in warehouse operations.

Pallet Racking vs Robotic Picking System Infographic

industrydif.com

industrydif.com