Bulk storage maximizes space by stacking large quantities of similar items without individual containment, ideal for uniform goods and high-volume inventory. Cube-based storage optimizes warehouse efficiency by organizing items within specific cubic volumes, enhancing accessibility and inventory management for diverse product ranges. Choosing between bulk and cube-based storage depends on product type, handling requirements, and warehouse layout to balance space utilization and operational efficiency.

Table of Comparison

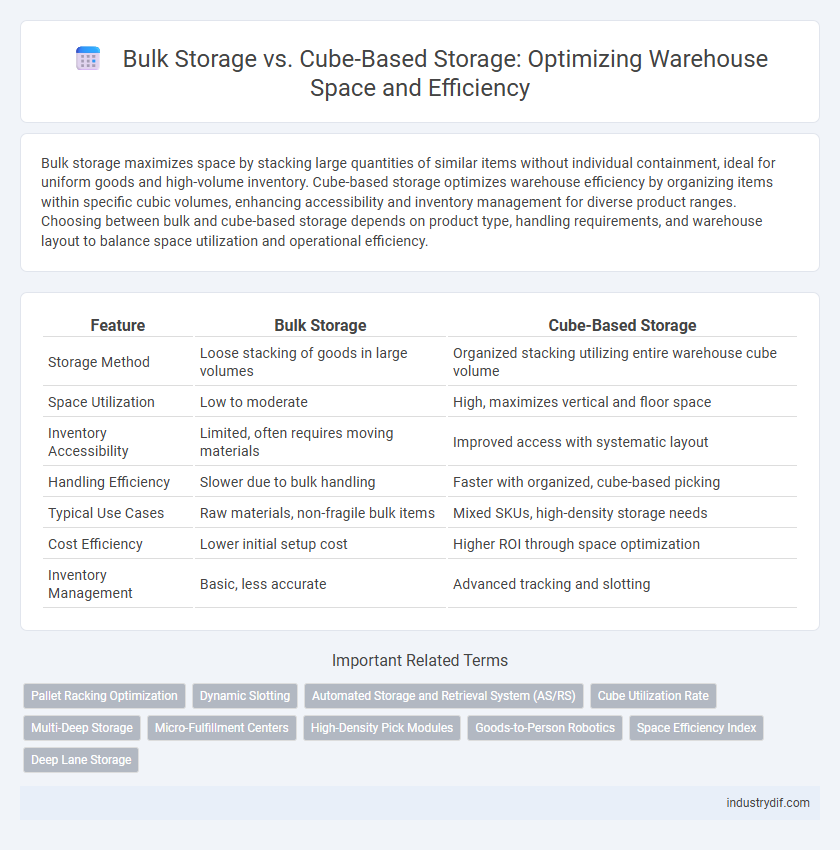

| Feature | Bulk Storage | Cube-Based Storage |

|---|---|---|

| Storage Method | Loose stacking of goods in large volumes | Organized stacking utilizing entire warehouse cube volume |

| Space Utilization | Low to moderate | High, maximizes vertical and floor space |

| Inventory Accessibility | Limited, often requires moving materials | Improved access with systematic layout |

| Handling Efficiency | Slower due to bulk handling | Faster with organized, cube-based picking |

| Typical Use Cases | Raw materials, non-fragile bulk items | Mixed SKUs, high-density storage needs |

| Cost Efficiency | Lower initial setup cost | Higher ROI through space optimization |

| Inventory Management | Basic, less accurate | Advanced tracking and slotting |

Introduction to Bulk and Cube-Based Storage

Bulk storage involves storing large quantities of homogeneous goods without the need for individual packaging, maximizing space utilization by stacking items directly on the warehouse floor or pallets. Cube-based storage, alternatively, optimizes the use of cubic space by organizing inventory based on the three-dimensional volume of storage units, often incorporating shelving systems or modular containers to enhance accessibility and density. Both methods play crucial roles in warehouse management strategies, influencing storage efficiency, retrieval speed, and inventory control.

Defining Bulk Storage in Warehousing

Bulk storage in warehousing refers to the method of storing large quantities of homogeneous products without individual packaging, typically placed directly on the floor or in large containers. This storage type maximizes space utilization by stacking items vertically and is ideal for high-volume, low-variety inventory such as grains, coal, or raw materials. Bulk storage enhances operational efficiency by reducing handling time and simplifying inventory management for goods that require minimal selectivity.

What is Cube-Based Storage?

Cube-based storage optimizes warehouse space by utilizing the entire volume, including height, rather than just floor area. This method employs tall shelving units and automated systems to maximize cubic capacity, improving inventory density. Cube-based storage enhances efficiency by enabling better organization and faster retrieval of goods within a fixed warehouse footprint.

Key Differences Between Bulk and Cube-Based Storage

Bulk storage in warehousing involves stacking large quantities of goods without individual containerization, maximizing space for uniform items but limiting accessibility. Cube-based storage optimizes space by organizing inventory according to three-dimensional volume, improving space utilization for irregularly shaped items and enhancing retrieval efficiency. Key differences include the trade-off between storage density in bulk systems versus precise spatial organization and ease of inventory management in cube-based storage solutions.

Space Utilization and Efficiency Comparison

Bulk storage maximizes space utilization by stacking goods without individual compartmentalization, ideal for homogeneous products but limiting accessibility and inventory control. Cube-based storage optimizes warehouse efficiency by using modular compartments or bins tailored to product dimensions, enhancing organization and retrieval speed at the expense of some cubic space. Warehouses prioritize bulk storage for high-density items, while cube-based systems suit diverse inventories requiring precise handling and faster turnover.

Impact on Inventory Management

Bulk storage enhances inventory management by maximizing floor space for large quantities of homogeneous products, reducing handling time but limiting product accessibility. Cube-based storage improves space utilization by optimizing vertical volume, enabling denser stacking and better organization of diverse SKUs, thus facilitating quicker retrieval and accurate stock control. Effective inventory systems leverage cube-based methods to improve picking efficiency and minimize stock discrepancies, crucial for maintaining supply chain responsiveness.

Cost Implications: Bulk vs Cube-Based Storage

Bulk storage minimizes initial capital expenditure by utilizing large, open floor areas for high-density stacking of homogeneous products, reducing racking costs. Cube-based storage, while involving higher upfront investment in specialized racking and automation systems, optimizes cubic space utilization and improves inventory accessibility, leading to lower operational labor costs over time. Evaluating cost implications requires balancing bulk storage's lower infrastructure expenses against cube-based storage's efficiency gains and reduced handling times.

Flexibility and Scalability in Storage Solutions

Bulk storage offers high flexibility by accommodating irregular and oversized goods without the need for specialized racking, making it ideal for variable inventory sizes. Cube-based storage maximizes space utilization through vertical stacking and modular racks, enabling scalable solutions that adapt to increasing inventory volume efficiently. Prioritizing flexibility and scalability in storage solutions optimizes warehouse operations by balancing storage density with easy access and quick reconfiguration.

Industry Suitability and Application Areas

Bulk storage systems excel in industries handling large volumes of homogeneous materials, such as agriculture, mining, and raw material manufacturing, where maximizing storage capacity for loose or palletized goods is crucial. Cube-based storage solutions are ideal for sectors like retail, e-commerce, and pharmaceuticals, where optimizing storage density and accessibility of diverse, smaller inventory items enhances order fulfillment efficiency. The choice between bulk and cube-based storage depends on factors like product type, storage space, and operational workflow requirements in various industrial applications.

Choosing the Right Storage Method for Your Warehouse

Selecting the appropriate storage method for your warehouse depends on inventory type, space utilization, and handling efficiency. Bulk storage maximizes volume capacity by stacking large quantities of homogeneous items directly, ideal for high-density, low-variety goods. Cube-based storage optimizes space using modular units and shelving, enhancing accessibility and organization for diverse SKUs with varied sizes.

Related Important Terms

Pallet Racking Optimization

Bulk storage maximizes space by stacking goods directly but often limits access and inventory visibility, while cube-based storage employs pallet racking systems to enhance vertical space utilization and improve accessibility. Optimizing pallet racking involves selecting configurations such as selective, drive-in, or push-back racks to balance storage density and retrieval efficiency, crucial for warehouse throughput and inventory management.

Dynamic Slotting

Dynamic slotting enhances bulk storage efficiency by continuously reorganizing inventory based on real-time demand and product velocity, reducing retrieval time and maximizing storage density. In cube-based storage, dynamic slotting optimizes space utilization by assigning products to locations that best fit their dimensional volume, improving accessibility and minimizing wasted cubic space.

Automated Storage and Retrieval System (AS/RS)

Bulk storage in Automated Storage and Retrieval Systems (AS/RS) maximizes warehouse capacity by stacking large quantities of homogeneous goods, optimizing space utilization and reducing handling time. Cube-based storage in AS/RS focuses on efficiently organizing diverse items based on volume, enhancing retrieval speed and inventory accuracy through precise spatial allocation.

Cube Utilization Rate

Cube-based storage maximizes warehouse efficiency by optimizing cube utilization rate, ensuring that every cubic foot of storage space is effectively used to accommodate inventory. Bulk storage, while suitable for large, homogeneous products, often results in lower cube utilization due to less precise spatial organization and higher aisle space requirements.

Multi-Deep Storage

Multi-deep storage in warehousing maximizes space utilization by stacking products multiple layers deep, significantly increasing storage density compared to single-depth or cube-based storage methods. This approach enhances inventory capacity without expanding footprint but requires advanced warehouse management systems to ensure efficient retrieval and minimize picking errors.

Micro-Fulfillment Centers

Bulk storage maximizes capacity by stacking large quantities of similar products, ideal for high-volume, low-variety inventory in micro-fulfillment centers focused on fast replenishment. Cube-based storage optimizes space utilization by storing discrete SKU units within defined cubic volumes, enhancing order accuracy and retrieval speed critical for micro-fulfillment operational efficiency.

High-Density Pick Modules

High-density pick modules maximize warehouse efficiency by utilizing bulk storage methods that prioritize volume over individual unit accessibility, allowing for increased storage capacity within a limited footprint. Cube-based storage optimizes space utilization by organizing inventory based on cubic volume, which enhances picking speed and accuracy in high-density environments through structured compartmentalization.

Goods-to-Person Robotics

Goods-to-person robotics enhances bulk storage efficiency by minimizing space through high-density stacking, enabling rapid retrieval without human movement. Cube-based storage maximizes vertical space utilization and inventory density, optimizing automated picking speed and accuracy in warehouses using robotic systems.

Space Efficiency Index

Bulk storage maximizes the Space Efficiency Index by utilizing large, open floor areas for storing homogeneous products with minimal handling, leading to high volumetric utilization but limited accessibility. Cube-based storage improves space efficiency through optimized vertical utilization and organized compartmentalization, enhancing inventory density and retrieval speed while maintaining a balanced Space Efficiency Index.

Deep Lane Storage

Deep lane storage maximizes warehouse density by stacking pallets multiple levels deep, prioritizing volume utilization over immediate accessibility. This bulk storage method suits high-volume, uniform inventory, enhancing space efficiency compared to cube-based storage that optimizes individual pallet access.

Bulk Storage vs Cube-Based Storage Infographic

industrydif.com

industrydif.com