Static storage assigns fixed locations to inventory, simplifying tracking but potentially wasting space and reducing flexibility. Dynamic slotting continuously reorganizes products based on demand, optimizing space utilization and improving picking efficiency. Warehouses that implement dynamic slotting can adapt to seasonal fluctuations and varied order profiles more effectively than those relying solely on static storage.

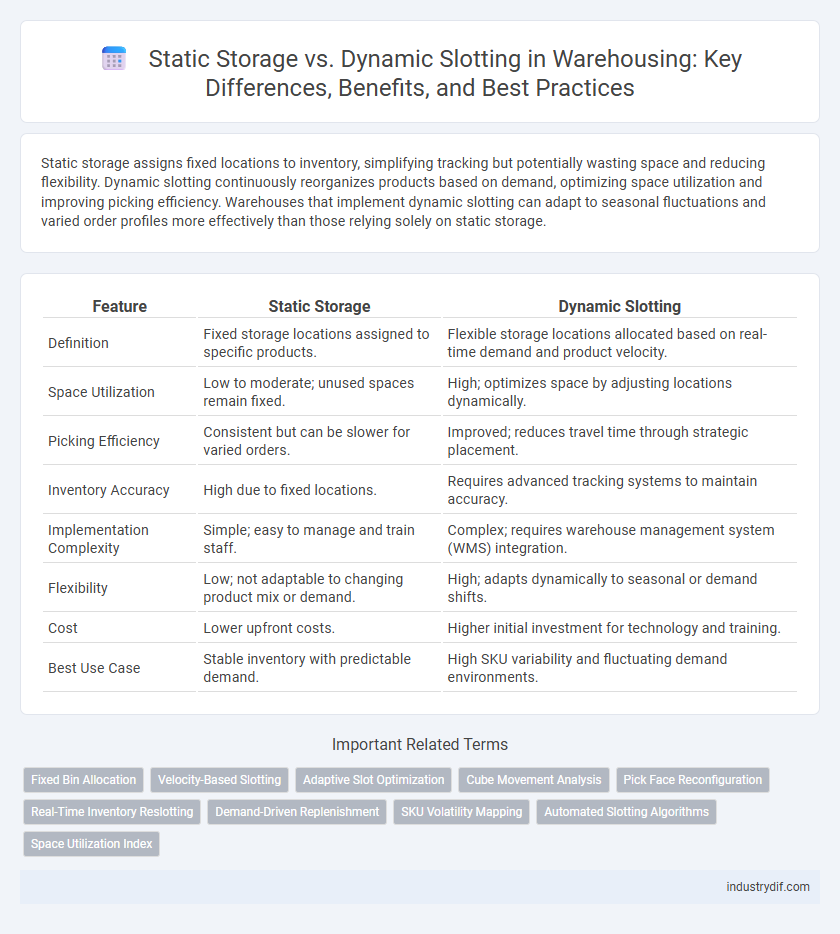

Table of Comparison

| Feature | Static Storage | Dynamic Slotting |

|---|---|---|

| Definition | Fixed storage locations assigned to specific products. | Flexible storage locations allocated based on real-time demand and product velocity. |

| Space Utilization | Low to moderate; unused spaces remain fixed. | High; optimizes space by adjusting locations dynamically. |

| Picking Efficiency | Consistent but can be slower for varied orders. | Improved; reduces travel time through strategic placement. |

| Inventory Accuracy | High due to fixed locations. | Requires advanced tracking systems to maintain accuracy. |

| Implementation Complexity | Simple; easy to manage and train staff. | Complex; requires warehouse management system (WMS) integration. |

| Flexibility | Low; not adaptable to changing product mix or demand. | High; adapts dynamically to seasonal or demand shifts. |

| Cost | Lower upfront costs. | Higher initial investment for technology and training. |

| Best Use Case | Stable inventory with predictable demand. | High SKU variability and fluctuating demand environments. |

Introduction to Static Storage and Dynamic Slotting

Static storage allocates fixed locations for inventory items, simplifying picking processes but potentially leading to inefficient space utilization when item demand fluctuates. Dynamic slotting regularly adjusts product locations based on real-time demand, enhancing storage density and reducing travel time during order fulfillment. Implementing dynamic slotting systems leverages warehouse management software to optimize slot assignments and improve operational efficiency.

Key Differences Between Static and Dynamic Storage

Static storage assigns fixed locations for inventory, ensuring predictability and simplifying space management but potentially leading to inefficient space utilization during fluctuating demand. Dynamic slotting adapts storage locations based on real-time inventory levels and product velocity, maximizing space efficiency and reducing picking time through continuous optimization. Key differences include flexibility, with static storage offering consistent placement and dynamic slotting providing adaptive storage solutions tailored to changing warehouse activity.

Advantages of Static Storage in Warehousing

Static storage in warehousing offers several advantages, including simplified inventory management and consistent product placement that reduces errors and speeds up picking processes. Fixed locations streamline training for warehouse staff, leading to increased operational efficiency and reduced labor costs. This method also allows for more predictable space utilization, making inventory control more reliable and warehouse layouts easier to optimize.

Benefits of Dynamic Slotting Systems

Dynamic slotting systems optimize warehouse space utilization by continuously adjusting product locations based on real-time demand and inventory turnover rates. This approach enhances picking efficiency, reduces travel time for warehouse staff, and minimizes operational costs compared to static storage models. Improved order accuracy and faster fulfillment cycles are direct benefits of implementing dynamic slotting in modern warehousing operations.

Operational Efficiency: Static vs Dynamic

Static storage assigns fixed locations for inventory items, simplifying retrieval but potentially leading to underutilized space and longer travel times. Dynamic slotting adjusts storage locations based on real-time demand and item velocity, optimizing space utilization and reducing picker travel distance. Implementing dynamic slotting systems enhances operational efficiency by improving order accuracy and throughput in high-volume warehouses.

Impact on Inventory Accuracy and Management

Static storage systems maintain fixed locations for inventory, simplifying tracking and enhancing inventory accuracy by reducing errors in item placement. Dynamic slotting optimizes space utilization by continuously adjusting storage locations based on demand patterns, improving inventory turnover but requiring advanced warehouse management systems to maintain accuracy. Effective inventory management depends on balancing the organizational simplicity of static storage with the flexibility and efficiency gains provided by dynamic slotting strategies.

Space Utilization in Static and Dynamic Schemes

Static storage assigns fixed locations for inventory, often leading to underutilized space due to varying product sizes and demand fluctuations. Dynamic slotting optimizes space utilization by continuously reallocating inventory slots based on real-time data and product velocity, maximizing warehouse density. This adaptive approach reduces wasted space and improves overall storage efficiency in warehousing operations.

Technology Requirements for Dynamic Slotting

Dynamic slotting requires advanced warehouse management systems (WMS) equipped with real-time data analytics and AI-driven algorithms to continuously optimize inventory placement. Integration with automated material handling equipment such as conveyors and robotics enhances responsiveness and throughput. Cloud-based platforms and IoT sensor connectivity enable seamless data exchange, supporting agile decision-making and efficient space utilization.

Selecting the Right Storage Method for Your Warehouse

Choosing between static storage and dynamic slotting depends on inventory turnover and product variety in your warehouse. Static storage is ideal for stable SKUs with low movement, maximizing space through fixed slot assignments. Dynamic slotting enhances picking efficiency by constantly adjusting locations based on real-time demand patterns, making it suitable for high-velocity and seasonal inventory.

Future Trends in Warehouse Storage Optimization

Future trends in warehouse storage optimization emphasize dynamic slotting, leveraging AI and machine learning to adapt storage locations based on real-time demand and product velocity, dramatically improving space utilization and picking efficiency. Static storage remains relevant for stable, slow-moving inventory due to its simplicity and predictability but is increasingly integrated with dynamic systems to balance efficiency and control. Advanced robotics and IoT sensors facilitate dynamic slotting by providing accurate inventory data and automated material handling, driving the future of warehouse storage toward highly flexible and responsive solutions.

Related Important Terms

Fixed Bin Allocation

Fixed bin allocation in static storage assigns specific inventory items to predetermined locations, enhancing consistency and reducing retrieval errors. Dynamic slotting optimizes space utilization by frequently reallocating inventory based on demand patterns, but fixed bin allocation offers stability that supports streamlined picking processes in warehouses.

Velocity-Based Slotting

Velocity-based slotting optimizes warehouse efficiency by categorizing inventory based on picking frequency, placing high-velocity items in accessible static storage locations to reduce travel time. This dynamic slotting approach enhances order fulfillment speed compared to traditional static storage, which assigns fixed locations without regard to item turnover rates.

Adaptive Slot Optimization

Adaptive slot optimization enhances warehouse efficiency by dynamically adjusting product locations based on real-time demand patterns, surpassing the limitations of static storage where items remain fixed. This dynamic slotting approach reduces picking times and increases throughput by continuously analyzing order data to optimize slot assignments for maximum space utilization and workflow efficiency.

Cube Movement Analysis

Static storage involves fixed slot assignments, resulting in limited cube movement analysis opportunities, whereas dynamic slotting constantly rearranges inventory locations based on cube utilization, enhancing space optimization and reducing travel time. Cube movement analysis in dynamic slotting leverages real-time data to maximize volumetric efficiency and improve throughput in warehouse operations.

Pick Face Reconfiguration

Static storage maintains fixed locations for inventory, creating predictable but less flexible pick face configurations that can lead to inefficiencies as demand patterns change. Dynamic slotting continuously adjusts pick face arrangements based on real-time data and order trends, optimizing space utilization and reducing travel time for warehouse workers.

Real-Time Inventory Reslotting

Real-time inventory reslotting enhances dynamic slotting by continuously analyzing order patterns and replenishment cycles to optimize product placement and reduce travel time in warehouses. Static storage, with fixed slot assignments, lacks the flexibility to adapt quickly to demand changes, resulting in less efficient space utilization and slower picking processes.

Demand-Driven Replenishment

Static storage allocates fixed locations for inventory, while dynamic slotting adjusts storage positions based on real-time demand patterns to optimize picker efficiency. Demand-driven replenishment leverages dynamic slotting to prioritize high-turnover items, reducing travel time and improving inventory accuracy.

SKU Volatility Mapping

Static storage allocates fixed locations for SKUs regardless of demand fluctuations, while dynamic slotting constantly adjusts SKU placements based on real-time SKU volatility mapping to optimize inventory accessibility and reduce handling time. SKU volatility mapping tracks frequent changes in order patterns, enabling warehouses to prioritize high-turnover items for dynamic positioning, enhancing operational efficiency and space utilization.

Automated Slotting Algorithms

Automated slotting algorithms optimize warehouse efficiency by dynamically assigning storage locations based on product demand, reducing travel time and improving space utilization compared to static storage that relies on fixed slot assignments. These algorithms analyze real-time data to adjust slotting, enhancing picking speed and inventory accuracy in high-volume warehousing environments.

Space Utilization Index

Static storage allocates fixed locations for inventory, resulting in lower Space Utilization Index due to inefficient use of available space. Dynamic slotting continuously rearranges products based on demand, maximizing the Space Utilization Index by optimizing slot occupancy and minimizing wasted storage areas.

Static Storage vs Dynamic Slotting Infographic

industrydif.com

industrydif.com